Located in Taiwan, Diing Kuen Plastic Machinery Co., Ltd. has been dedicated to the research, development, manufacturing, and sales of monofilament extrusion machines. With over 40 years of experience, expertise, and active collaborations with foreign partners, Diing Kuen's monofilament extrusion machines incorporate the latest technology and feature automated control systems, offering user-friendly operation and efficient production of high-quality monofilament yarn, leading the international market.

As a 100% Taiwan-made product, Diing Kuen machinery is exported to over 99% of overseas markets. With a global network of technical agents and service centers, Diing Kuen provides customers with immediate technical support. The company maintains excellent cooperative relationships with international enterprises in countries such as Vietnam, the Philippines, Turkey, Portugal, Morocco, Mexico, Peru, and others.

Meeting the Demands of High Tensile Strength and High Elasticity Applications

Diing Kuen's monofilament extrusion equipment not only produces monofilaments with a range of 8-12 GPD, but their special machinery can even achieve 15 GPD. Each fiber's tensile strength is enhanced, surpassing the previous pursuit of a 7-8 times elongation ratio to perform 10 times or even 15 times. When comparing two ropes of the same size, a typical rope can withstand 5 tons, while Diing Kuen's equipment can produce a special rope capable of withstanding 10 tons, highlighting its superior quality advantage in terms of high tensile strength.

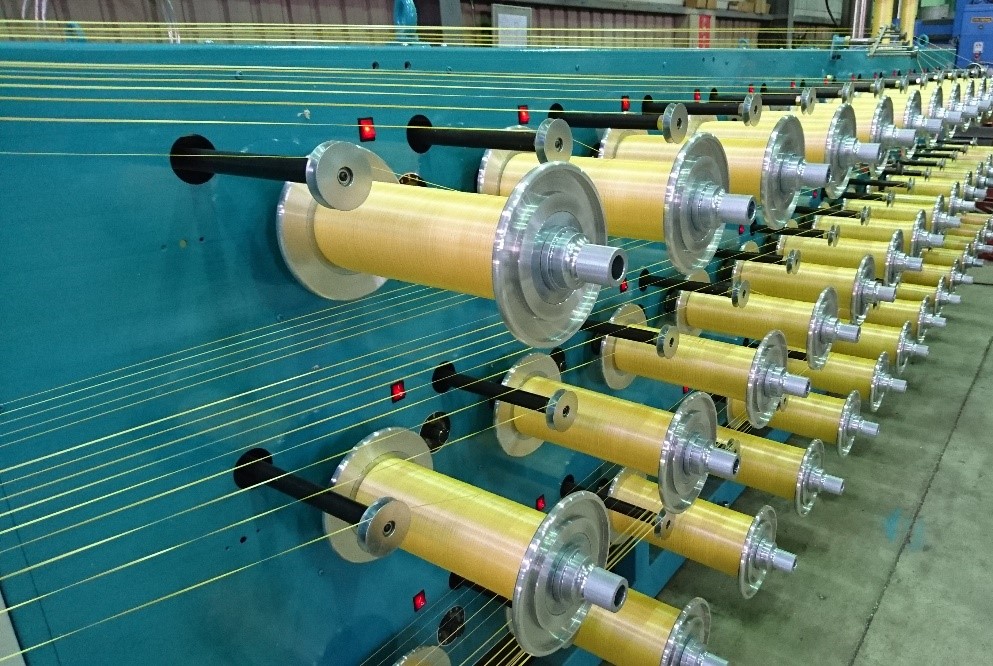

Continuous Yarn Production at 400 m/min High Speed

Through well-coordinated machine structure design and auxiliary equipment, Diing Kuen meets the requirements of 24-hour non-stop production. During the monofilament production process, Diing Kuen's equipment can operate at high speeds of 200-250 m/min or even 400 m/min, significantly reducing material waste and saving time costs for customers.

Aquaculture Nets / Long-Distance Shipping Container Nets / Textile Industry

After undergoing various processing and auxiliary equipment, the monofilaments exhibit excellent elasticity, toughness, tensile strength, and durability. They can be applied in industries such as aquaculture, fishing, long-distance shipping for nets, fishing lines, fish farming cage nets, ropes, and more.

In the fashion and textile industry, the use of fine and elongated monofilaments allows for the weaving of lightweight, soft, comfortable, and highly stretchable fabrics. When the monofilaments are delicate enough, they can be used to create high-end textile products such as premium suits, lace and embroidery, bed sheets, curtains, carpets, automotive accessories, and more.

Environmentally Friendly and Economical, 30% Increase in Production Capacity

With the global increase in environmental awareness and challenges such as power restrictions and carbon footprints, Diing Kuen provides diverse solutions to overseas customers, successfully overcoming power limitations and increasing production capacity by 30%. As the Asian market emphasizes the circular economy and countries implement plastic reduction policies, Diing Kuen embarked on the development of environmentally friendly industrial product lines years ago. Today, they possess mature and innovative technologies to meet customers' specific precision requirements for high-quality product lines.

Pioneering Digital Transformation in the Market

Diing Kuen has implemented an automated system to control temperature, pressure, equipment monitoring, equipment lifespan, and repair reporting. Through IoT technology, they collect large-scale data, providing real-time feedback to customers' mobile devices, enabling them to monitor production progress and reduce human error rates.

Long Service Life and High Production Stability

Diing Kuen dispatches a professional commissioning team to assist customers with assembly, calibration, and testing on-site. They also arrange proper education and training, guiding customers' production teams in correct operation and maintenance methods, ensuring excellent after-sales service and product durability. With superior manufacturing quality and Diing Kuen's guided operating procedures, the equipment can have a lifespan of over 20 years.