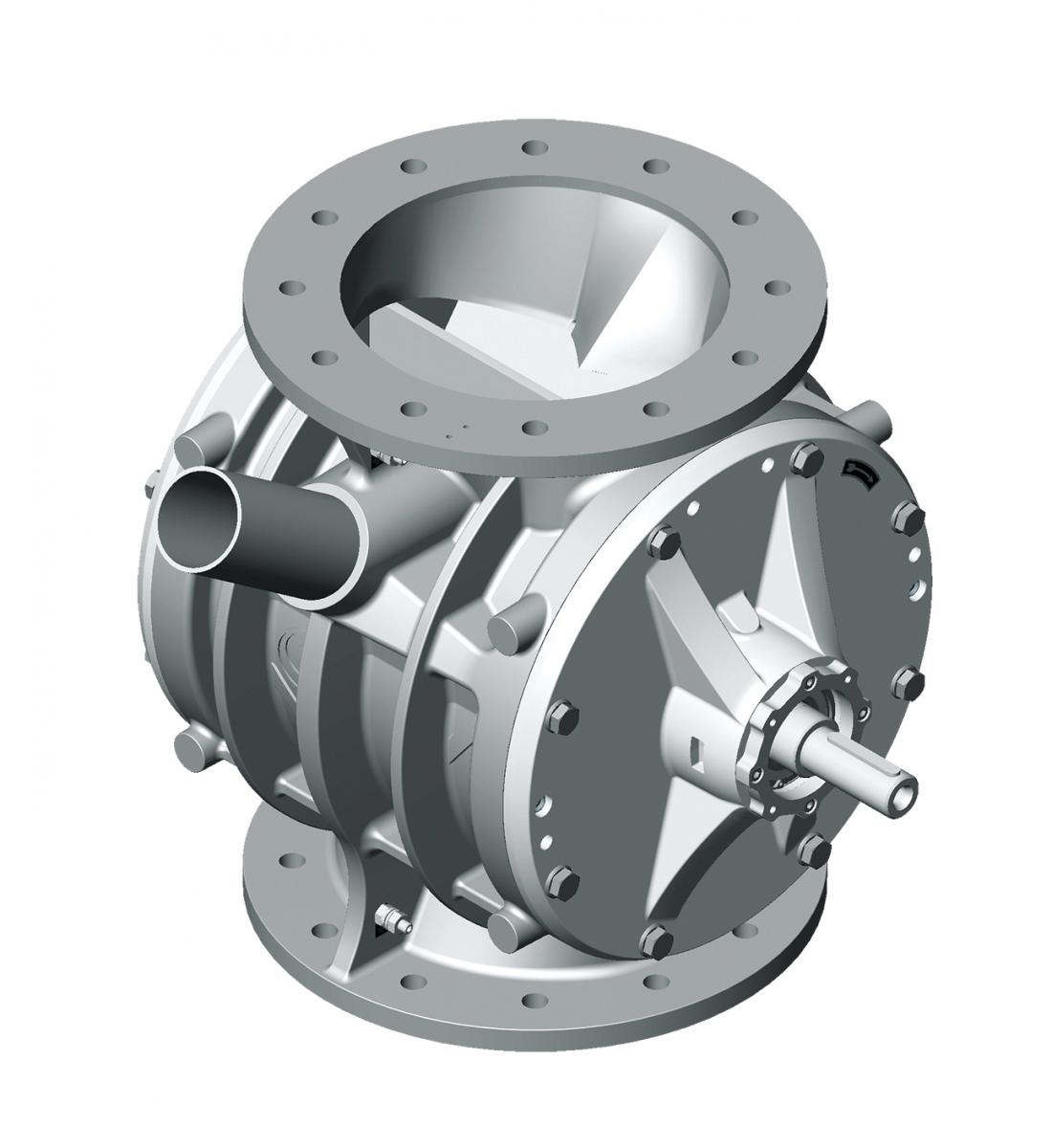

COPERION made improvements to its ZVB rotary valve design, making sure to provide the gentlest mode of material handling as well as meeting the sanitary standards of the food and pet food industries. The rotary valves now feature a lower overall weight while maintaining the same robust design, optimisation of the housing wall thicknesses, increased inlet cross section, and especially an optimised inlet geometry for fragile food materials such as pet food kibbles, roasted coffee and finished cereals.

The Coperion ZVB rotary valve is a stainless steel rotary valve for gentle handling of the most fragile food and pet food materials. (Photo: Coperion, Weingarten/Germany)

This unique combination results in a much gentler handling and introduction of product to the rotary valve. The increased “anti-chopping” inlet deflects the product into the rotating rotor chambers of the rotary valve and avoids that the product is damaged by the metering vanes. Several tests with customers have shown a significant reduction in product degradation of fragile and sensitive materials such as pet food kibbles, compared to common rotary valves with standard inlet geometries. Furthermore, an improved overall capacity through the valve is realized by the larger, optimised inlet cross section.

Ideal applications include positioning the rotary valve to meter and load finished product into big bags or supersacks, or for filling of finished product packaging lines. All automated transfer of product is then done without degradation or “chopping” of the finished product or ingredient.

In addition to the modifications outlined above, the Coperion ZVB rotary valves are also available in Coperion’s innovative design for wet cleaning (e.g. Clean in Place). The overall design is engineered to provide optimum operational reliability for sanitary production. In addition to including materials of construction and design for use with cleaning agents or hot water flushing, the valve can be equipped with flush end sealing at the inlet and outlet and between side covers and the housing.

Artículos deportivos para ni?os