成立于1987年的Sawawada公司是世界级的熔模铸造生产商,同时还可提供一流的粗铸件及成品部件。Sawawada还在质量、成本效率、准时交货及优质服务方面具有较高声誉。

You don't have to be a big international brand, or have subsidiaries and representatives in every far flung corner of the earth, to bask in an international reputation and with orders to keep your investment casting and CNC machines purring through one year into the next. Perhaps all you need is the gutsy and confident approach of Taiwan's Sawawada Corp. that started out in 1987 as a private company and that twenty three years later is still a private company but a "world-class" manufacturer of precision metal parts made to customer specifications on an OEM and ODM basis. International Sales Manager Celine Chou took time out to chat with International Metalworking News for Asia (IMNA) reporter David Monson at the company's administrative headquarters in Jhongshan District of Taipei in late May.

IMNA: Many companies make metal parts but not many can speak about the range and variety you can. Give us some idea of how broad this is? Chou: Well I have to say first and foremost that, as Taiwan Company's go, we're a small to medium sized OEM company with a single factory about an hour's drive from Taipei city. We have about a 60 strong workforce and, as you will note from our product range, a quite large industrial footprint. Being relatively small means that we're flexible and able to adapt very nimbly to the demands of our customers.

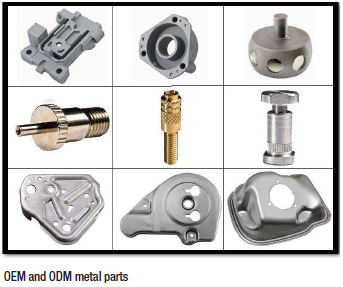

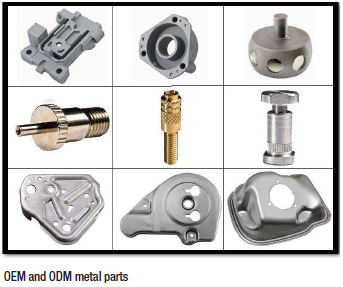

IMNA: So a broad range of industries too. Which of them would you consider the most profitable at the present time? Chou: We don't quite look at it like that. No one industry or type of product is more important or profitable than the other for us. Our products cover a wide range of industries and commercial applications. We make to order everything from stainless steel architectural hardware and electronic component parts to those for the automotive industry. It all depends on the material we use for any particular line of products whether they're cast in tool steel, alloy steel, stainless steel or carbon steel. You name it and we're able to do it. And you have to remember that we're also into secondary operation - that means everything that comes after initial casting like machining, tapping, heat treating, polishing, vibratory, plating, sub-assembly and finishing. It all depends on the customer's requirements. You could say, in a nutshell, that although we don't make a complete product as such we are able to make a 'complete metal part' - a part that the client is able to immediately drop into place, whether it is being used in a building or a car.

IMNA: What industries have undergone growth surges in recent years or months that have given a special boost to your production? Chou: Without hesitation I would say mechanical parts. To get some idea of the demand you only have to think of the automotive industry and all the parts you use in get around on four wheels - from disc brakes, wheel spacers and water pumps to spark plugs and thermostats. The list is almost endless.

IMNA: To do this you have a full house of state of the art machinery and technology - investment casting, and CNC machining and so on. Does this also suppose a high level of automation then in your production process?

IMNA: To do this you have a full house of state of the art machinery and technology - investment casting, and CNC machining and so on. Does this also suppose a high level of automation then in your production process? Chou: One thing any company that intends to stay competent and profitable these days has

Air Max You don't have to be a big international brand, or have subsidiaries and representatives in every far flung corner of the earth, to bask in an international reputation and with orders to keep your investment casting and CNC machines purring through one year into the next. Perhaps all you need is the gutsy and confident approach of Taiwan's Sawawada Corp. that started out in 1987 as a private company and that twenty three years later is still a private company but a "world-class" manufacturer of precision metal parts made to customer specifications on an OEM and ODM basis. International Sales Manager Celine Chou took time out to chat with International Metalworking News for Asia (IMNA) reporter David Monson at the company's administrative headquarters in Jhongshan District of Taipei in late May. IMNA: Many companies make metal parts but not many can speak about the range and variety you can. Give us some idea of how broad this is? Chou: Well I have to say first and foremost that, as Taiwan Company's go, we're a small to medium sized OEM company with a single factory about an hour's drive from Taipei city. We have about a 60 strong workforce and, as you will note from our product range, a quite large industrial footprint. Being relatively small means that we're flexible and able to adapt very nimbly to the demands of our customers. IMNA: So a broad range of industries too. Which of them would you consider the most profitable at the present time? Chou: We don't quite look at it like that. No one industry or type of product is more important or profitable than the other for us. Our products cover a wide range of industries and commercial applications. We make to order everything from stainless steel architectural hardware and electronic component parts to those for the automotive industry. It all depends on the material we use for any particular line of products whether they're cast in tool steel, alloy steel, stainless steel or carbon steel. You name it and we're able to do it. And you have to remember that we're also into secondary operation - that means everything that comes after initial casting like machining, tapping, heat treating, polishing, vibratory, plating, sub-assembly and finishing. It all depends on the customer's requirements. You could say, in a nutshell, that although we don't make a complete product as such we are able to make a 'complete metal part' - a part that the client is able to immediately drop into place, whether it is being used in a building or a car. IMNA: What industries have undergone growth surges in recent years or months that have given a special boost to your production? Chou: Without hesitation I would say mechanical parts. To get some idea of the demand you only have to think of the automotive industry and all the parts you use in get around on four wheels - from disc brakes, wheel spacers and water pumps to spark plugs and thermostats. The list is almost endless.

You don't have to be a big international brand, or have subsidiaries and representatives in every far flung corner of the earth, to bask in an international reputation and with orders to keep your investment casting and CNC machines purring through one year into the next. Perhaps all you need is the gutsy and confident approach of Taiwan's Sawawada Corp. that started out in 1987 as a private company and that twenty three years later is still a private company but a "world-class" manufacturer of precision metal parts made to customer specifications on an OEM and ODM basis. International Sales Manager Celine Chou took time out to chat with International Metalworking News for Asia (IMNA) reporter David Monson at the company's administrative headquarters in Jhongshan District of Taipei in late May. IMNA: Many companies make metal parts but not many can speak about the range and variety you can. Give us some idea of how broad this is? Chou: Well I have to say first and foremost that, as Taiwan Company's go, we're a small to medium sized OEM company with a single factory about an hour's drive from Taipei city. We have about a 60 strong workforce and, as you will note from our product range, a quite large industrial footprint. Being relatively small means that we're flexible and able to adapt very nimbly to the demands of our customers. IMNA: So a broad range of industries too. Which of them would you consider the most profitable at the present time? Chou: We don't quite look at it like that. No one industry or type of product is more important or profitable than the other for us. Our products cover a wide range of industries and commercial applications. We make to order everything from stainless steel architectural hardware and electronic component parts to those for the automotive industry. It all depends on the material we use for any particular line of products whether they're cast in tool steel, alloy steel, stainless steel or carbon steel. You name it and we're able to do it. And you have to remember that we're also into secondary operation - that means everything that comes after initial casting like machining, tapping, heat treating, polishing, vibratory, plating, sub-assembly and finishing. It all depends on the customer's requirements. You could say, in a nutshell, that although we don't make a complete product as such we are able to make a 'complete metal part' - a part that the client is able to immediately drop into place, whether it is being used in a building or a car. IMNA: What industries have undergone growth surges in recent years or months that have given a special boost to your production? Chou: Without hesitation I would say mechanical parts. To get some idea of the demand you only have to think of the automotive industry and all the parts you use in get around on four wheels - from disc brakes, wheel spacers and water pumps to spark plugs and thermostats. The list is almost endless.  IMNA: To do this you have a full house of state of the art machinery and technology - investment casting, and CNC machining and so on. Does this also suppose a high level of automation then in your production process? Chou: One thing any company that intends to stay competent and profitable these days hasAir Max

IMNA: To do this you have a full house of state of the art machinery and technology - investment casting, and CNC machining and so on. Does this also suppose a high level of automation then in your production process? Chou: One thing any company that intends to stay competent and profitable these days hasAir Max

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login