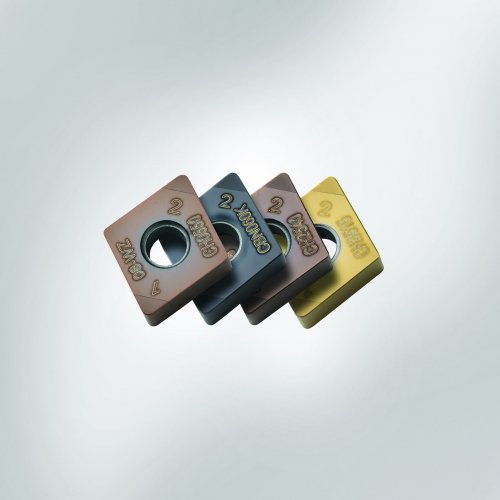

The addition of three grades to join the existing Secomax™ CBN060K completes the company’s premium offering for precision machining of hardened steel workpiece materials for continuous to heavy interrupted cuts.

The product range now includes CH0550, CBN060K, CH2540 and CH3515 to cover a wide range of applications from ISO H05 to H35. The grades use a new bimodal substrate with coarser grains to maximize toughness and wear resistance for high productivity and long tool life in various machining conditions. They are well suited for the automotive segment for components such as gears, shafts, rings, CV-joints and pinions that go in the gearbox and driveline of motorcycles, cars and trucks. Other application areas are in the mold and die and bearing segments.

CH0550 for ISO H05 is a completely new low-CBN grade designed for continuous cuts with smooth entries and exits. It consists of the new 40%-CBN substrate topped with a completely new, patent pending nanolaminate coating with a much higher Ti-content than other TiAlN coatings. This gives extra wear resistance to withstand crater wear and high temperatures at high cutting speeds and generates good surface finishes.

The existing CBN060K for ISO H15 is a tough grade used for continuous and light interrupted cuts at low and moderate cutting speeds. It also handles high feeds very well. CBN060K contains 60 percent CBN and has a TiCN binder with metal super alloy additives. The coating is a Seco unique and patented nanolaminate coating consisting of TiAlN and TiSiN.

With chamfered entries to prolong tool life, the new CH2540 for ISO H25 has a CBN content of 65% and is designed for interrupted cuts and for mixed operations with both interrupted and continuous cuts. Its substrate design, which is based on the new grade platform with bimodal grain distributions, improves wear resistance and enables it to handle moderate to high cutting speeds. Common uses include machining of gear teeth and over drilled holes.

CH3515 for ISO H35 is the toughest grade in this new PCBN grade chain and recommended for heavy interruptions when machining hardened steels. The grade contains 90 percent CBN with grain sizes of 2-4 µm in an AlN binder and has a TiAlN coating, which improves tool life. This grade can also be used for powder metallurgy (PM) materials with good results thanks to its high CBN content and toughness.