OMRON Corporation’s Color Mark Photoelectric Sensor E3S-DC Series (E3S-DC) and Color Fiber Amplifier Unit E3NX-CA Series (E3NX-CA) are designed to detect color marks (*1) printed on diversified food and beverage packages including glossy or colorful materials with subtle differences in colors and those previously difficult to detect. This capability will allow companies to cut back on time necessary to start production and maintenance work, contributing to an overall productivity increase in the packaging process.

Addressing an issue in food and beverage industry

The food and beverage industry, which has to meet varying consumer demands, develop new products almost on a daily basis, diversifying packaging materials and designs in the process. Given such circumstances, manufacturers have been looking for a sensor that can easily detect color marks printed on all sorts of materials in order to keep their plant running well. The sensor and amplifier will be showcased at the FOOMA JAPAN 2016 at Tokyo Big Sight from June 7 to 10.

With its customers, OMRON which is based in Kyoto, Japan, developed the E3S-DC and E3NX-CA which incorporate its proprietary sensing technology and algorithm to detect “differences in colors” under various conditions. Together the E3S-DC and E3NX-CA not only reliably detect color marks on a variety of packaging materials but also optimize initially set parameters to adjust to changes in manufacturing lots, contributing to a stable operation of the production plant.

The Super High Dynamic Range function requires only a simple setting to detect color differences between marks and the background printed on glossy materials including aluminum vapor deposition film. - The Low Noise, High S/N Ratio Light Receiving System detects subtle differences in similar types of color often used on colorful packaging with little color differences.

Color information detected by a sensor will be transmitted to upper layer equipment such as a programmable logic controller via EtherCAT (R). Color variations resulting from various lots can be easily managed in a database and sensors can be adjusted for optimal settings to keep the plant from an abrupt shutdown and maintain a high operational ratio.

OMRON brings innovation to manufacturing sites through automation with integrated, intelligent and interactive concepts. OMRON will continue to work with manufacturing partners to innovate manufacturing processes at the workplace with one of the world's most sophisticated Input-Logic-Output-Robotics + Safety (ILOR+S) technology including proprietary sensing technology.

Key features

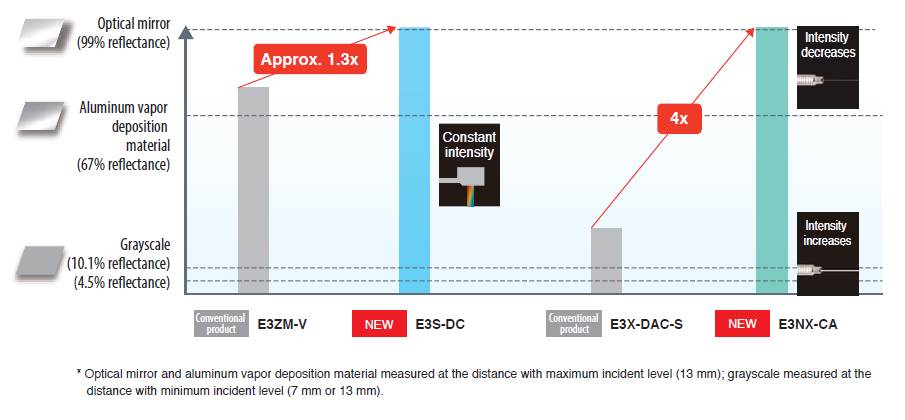

1. High Dynamic Range for No Saturation Even with 99% Reflective Optical Mirrors In order to detect highly-reflective glossy packaging, the installation angle of a sensor needed to be adjusted to avoid saturation of the sensor's incident level. The new Color Mark Sensor has a greatly widened incident light range. This allows for the stable detection of glossy aluminum vapor deposition packaging without saturation even if the Sensor is installed directly above it.

2. High S/N Ratio System Design to Identify Even Minor Color Differences With designs becoming more colorful, there are times where there is little difference in color between the color mark and the design elements (background), and it possibly causes false detection of color marks. The new Color Mark Sensor provides a high S/N ratio to stably detect subtle color differences.

3. RGB Data Transmission Function for Visualization of Color Variation There are cases where colors of packaging materials vary from lot to lot, which may cause production downtime due to false detection of color marks. The new Color Mark Sensor enables RGB information for color marks and backgrounds for each lot to be transmitted to a host device, and the RGB information can be quantified. The Sensor helps reduce downtime due to false detection of color marks caused by variation in colors printed on packaging and also the time required for measures taken against it.

*1 Marks which indicate the cutting positions of film packaging. The marks are printed on the film at regular intervals in colors varying with packaging design.

Adidas