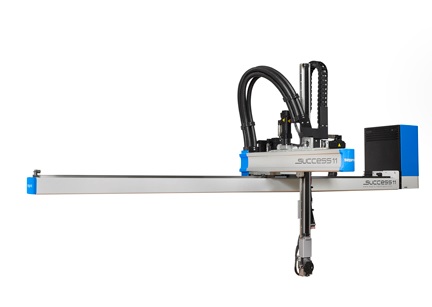

Demonstrating the productivity-improvement potential of cell automation in plastics injection molding, Sepro America exhibited at Plastec West 2019 (Feb. 5 – 7, Convention Center in Anaheim, CA). The company demonstrated a Sepro 6X-90L 6-axis articulated-arm robot and a Sepro Success 11 Cartesian beam robot with telescoping arm collaborate in insert loading and part removal, along with an S5 Picker.

In the demonstration cell, the two robots took turns picking parts from a simulated injection mold, placing them on a conveyor and then picking them off the other end of the conveyor and placing them back on the “mold” cores. It illustrated capabilities like insert pick-up and placement, part removal and accurate positioning for post-mold operations.

“For years we have been saying that robots should be expected to do much more than simply replacing a machine operator for part removal,” says Jim Healy, Vice President, Sales & Marketing. “Today, as interest in Industry 4.0 grows, more and more of our customers are discovering that they can, in fact, make added-value parts and improve productivity, by harnessing the potential of automation.”

A key component is Sepro’s proprietary Visual control platform. Developed specifically for plastics injection molding, the control can be customized to control the simplest sprue picker or the most advanced 3-, 5- or 6-axis robots. It can control one robot or an entire automation cell, including robots and pre- and post-mold peripheral equipment like insert feeders, vision systems, assembly and palletizing equipment. Several different levels of integration with one or more molding machines are available. These include full integration with the IMM control. When fully integrated, the robot application program runs in the IMM control and all application data, including robot programming and possibly other auxiliary equipment like mold temperature controls, are filed in one place in the IMM control memory.

Sepro’s display also features the S5 Picker, a versatile beam-mounted Cartesian sprue picker with 3 servo-driven axes. Based on the same basic mechanical design as the Sepro Success range of economical, general-purpose robots, it is compact and fast cycling, with take-out times as quick as 0.7 second and overall cycle times as short as 3 seconds. Sized for IMMs from 20 to 200 tons, S5 Pickers are fitted with a simple sprue gripper, but it can be supplied optionally with an R1 wrist rotation and can operate simple end-of-arm tooling. At the show, the picker operating space is protected by a laser light curtain. If a person approaches the robot while it is operating, the sensors will signal the Sepro control, which will first slow the robot and eventually stop its motion entirely to prevent operator injury or damage to the equipment.

Sepro showed off a total of five robots at Plastec West 2019.

Test running, chaussures, montres cardio gps et habits sports