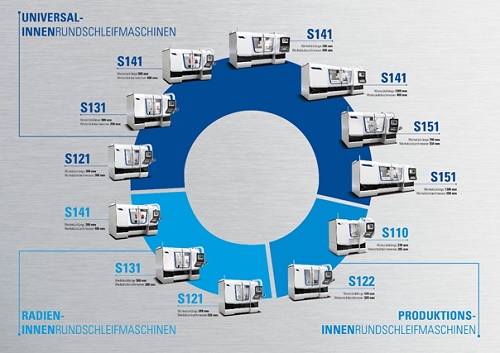

85 years later STUDER offers what is probably the world's largest portfolio in internal cylindrical grinding, with a range of 12 machines.

Kptec Components GmbH from Schorndorf (Germany) is a component manufacturer for the machine tool industry. The focus is on spindles, rotors, spindle housings, draw rods and flange parts. The core competence is grinding. "Achieving micrometer precision in series is the great challenge in grinding", states Walter Wiedenhöfer, Managing Director of Kptec Components. In the manufacture of spindle components, coaxialities of one micrometer are state-of-the-art. It is often necessary to grind an H6 fit into bores up to 400 mm deep for the clamping mechanisms of the interface. In addition, the machine must produce as economically as possible. In other words: You should only pick up the component once and then produce it completely, if possible. But a good machine must also be flexible and capable of performing unusual operations, such as relief grinding of a spindle, for instance. A machine that fulfils such requirements is the S151 universal internal cylindrical grinding machine. When fully equipped, it has three internal and one external grinding spindle, as well as a measuring probe. Kptec was convinced by it. Today, Wiedenhöfer comments: "This machine is the best we have in the company – it was absolutely the right decision to buy a STUDER machine.

The universal machines

STUDER has the right machine for every requirement in internal cylindrical grinding. In the universal range these are the S121, S131, S141 and the S151. The affordable universal S121 is the ideal machine for internal, surface and external grinding of chuck components. The S131, S141 and S151 form a series for every conceivable application in internal cylindrical grinding. They are used wherever the highest precision and efficiency are required – for example, for flange parts, spindle shafts, spindle housings, rotor shafts, bushes and much more. The maximum workpiece weight is 250 kg, and the maximum length is 1300 mm.

For production

The S110 is a very flexible and compact internal cylindrical grinding machine, ideal for chuck applications for individual components through to small batch production. Thanks to its small footprint it can fit in any workshop. The S122 is specialized for small bores and has a swing diameter of 220 mm. It offers cutting-edge technology for machining small to medium-sized workpieces in small to large-scale production. Both types have up to three grinding spindles in a parallel arrangement, which enable external and internal grinding in a single clamping. "Price, quality, technical requirements – these were our selection criteria for a new machine. The biggest advantage is the high production capacity", Miroslav Martinek, Production Manager at Sellier & Bellot, explains his decision to invest in an S110.

Three sizes for radii

The S121, S131 and S141 are the experts for high-precision internal cylindrical grinding of radii, spheres, balls, cones and diameters. The maximum swing diameter is 400 mm and the maximum workpiece weight is 100 kg. The main fields of application are in the manufacture of die plates from carbide and ceramic and the production of hydraulic components such as axial pump pistons, guide plates and housings from hardened steel, cast iron and copper. The application range also includes workpieces made of industrial ceramic, sapphire and carbide for the manufacture of human implants. The automatic B-axis with direct drive allows grinding with interpolation for high-precision machining of radii. The radius grinding machines are supported by the StuderSIM software. AKS Hartmetalltechnik GmbH in Schwäbisch Gmünd has an S131 – with radius grinding option. "The sophisticated CNC technology, the ability to execute several work steps in a single clamping whilst achieving absolute precision. These criteria convinced us. Set-up times, maintenance costs and failure times can now be calculated. We also benefit from the fast response times of STUDER Customer Care", explains Production Manager Edgar Feifel.

Solid construction

The internal cylindrical grinding machines are based on the Granitan® machine bed with its excellent damping behavior and StuderGuide® guideway system. This system's big advantage in comparison with hydrostatic guides is the damping component in the direction of movement. The dressing process can be flexibly and optimally adapted to the workpiece, tool and material-specific characteristics - according to the customer's requirements. A further STUDER speciality is the grinding wheel reference points (T-numbers). These enable programming with normal dimensions, which considerably facilitates the development of grinding programs. The workhead can be moved in a longitudinal direction on the swiveling B-axis, has a high roundness accuracy and is low-maintenance. The airlift simplifies adjustment when setting up or resetting the workhead.

Sophisticated sensor technology monitors the process during grinding and dressing and offers simple registration of grinding wheel and workpiece. The air-gap elimination serves for reducing the cycle time. The modular spindle concept enables optimal adaptation to the grinding task. The direct drive in the grinding spindle turret offers minimal positioning ranges on the radius and universal grinding machines (except S110/S122). On the S122 the high-precision machining of minimal diameters can also be done efficiently, thanks to the proven arbor deflection compensation.

Different loading systems are available for automation. Thanks to their modular design, these can be precisely adapted to the machine application and machining processes. Appropriate peripheral devices guarantee seamless integration into the respective production process.

Anyone can be a grinding expert

It is no longer necessary to be a grinding expert to operate the machine. You only need to know what the workpiece is made of and what the surface quality of the workpiece must be at the end of the process. StuderTechnology suggests the optimal grinding parameters and generates the program. StuderWIN offers the possibility of fully integrating the in-process gauging and sensor technology for process monitoring, including contact detection and automatic balancing systems in the operator interface. This enables standardized programming of the different systems. StuderWIN is supplemented by the StuderPictogramming grinding software. The operator strings the individual grinding cycles together – the control unit generates the ISO code. The machine's functionality is enhanced by the software option for thread and form grinding. The StuderSIM software has been specially developed for the internal grinding of radii. The operating system enables programming of all basic cycles for grinding, dressing and process-supporting measurement. This type of programming guarantees high flexibility together with maximum user-friendliness. After programming, the process can be simulated and optimized. This ensures reliability, as well as guaranteeing short programming times and increased cost effectiveness.

Conclusion

There is hardly a workpiece that cannot be machined with the STUDER internal cylindrical grinding machines. The Swiss grinding machine manufacturer offers the right machine for all conceivable applications. The excellent ergonomics of the machines ensures comfort for the operator and also enhances the machine value.

Air Max 95 VaporMax