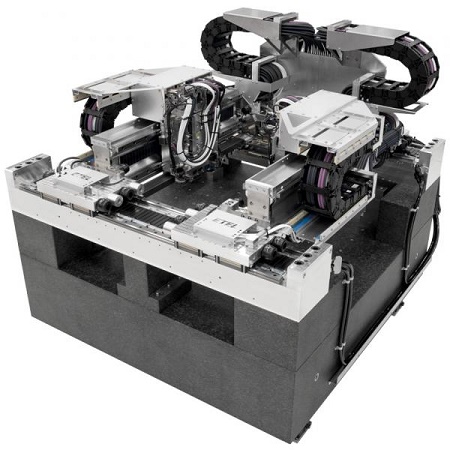

ETEL launches TELICA, its new multi-axes platform primarily dedicated to semiconductor back-end applications. Its dual gantry architecture provides motion along 3 degrees of freedom, X, Y and Z, for a total number of 8 controlled axes. It is designed to fulfill the most challenging requirements of advanced die bonding processes (Flip-chip, Fan-out, 3D stacked packages), µ-LED bonding, dispensing applications and more.

By design, conventional motion system architectures are EITHER optimized for high positioning accuracy OR high throughput. Thanks to a very innovative motion system architecture, TELICA meets BOTH SIMULTANEOUSLY with ±1 µm global placement accuracy (blind move) at a throughput of 10 kUPH for a typical flip chip die bonding application and up to 180 kUPH for µ-LED bonding.

TELICA is available in two standard variants: variant 1 for Wafer Level Packages (WLP) with X410 x Y445 x Z30 mm travels and variant 2 for Panel Level Packages (PLP) with X750 x Y800 x Z30 mm travels.

TELICA introduces a new metrology approach drastically reducing the Abbé errors as well as the relative positioning mismatch between process tool and substrate. Multi-dimensional encoders ensure the high placement accuracy while water cooled ironcore motors allow extreme duty cycles.

Coupled with ETEL's state-of-the-art AccurET controllers, the TELICA platform benefits from multiple control features such as: zero settling time, non-linear control, advanced feedforward and trajectory filters, full synchronization of all axes with nanosecond jitter, a specific gantry control algorithm, multidimensional mapping, advanced triggering capabilities based on real mapped position, advanced software diagnostic and system identification tools for control optimization.

KD VIII Elite High