FROM the ubiquitous hand-pump for ketchup on French fries or cheese on nachos to peristaltic pumps for ice cream and slushies, types of food and beverage dispensing equipment vary. Products dispensed by this equipment also vary and include everything from alcohol to soft drinks from dairy to juice and from coffee to condiments. Many of these product categories also feature highly specific and often diverse characteristics. For instance, wine and beer products contain ethanol – a solvent – which can be harmful to many materials. Yogurt, ice cream and milk can accelerate bacterial growth on tubing surfaces if not properly sanitized with cleaning chemicals.

Therefore, resistance properties, such as chemical, corrosion, abrasion and pressure – in varying degrees – are critical to the performance of food and beverage dispensing tubing as well the equipment as a whole. And because dispensing equipment is used under varying levels of pressure as well as extreme temperatures, the durability of components is significantly important. Dispensing tubing, though a small component, can have a major impact on the overall effectiveness of both dispensing equipment and an operation. As a result, determining, designing and implementing the appropriate food and beverage dispensing tubing solutions is a critical step to ensuring the quality, consistency and safety of a product – not to mention it can help to reduce operational downtime and offer long-term savings.

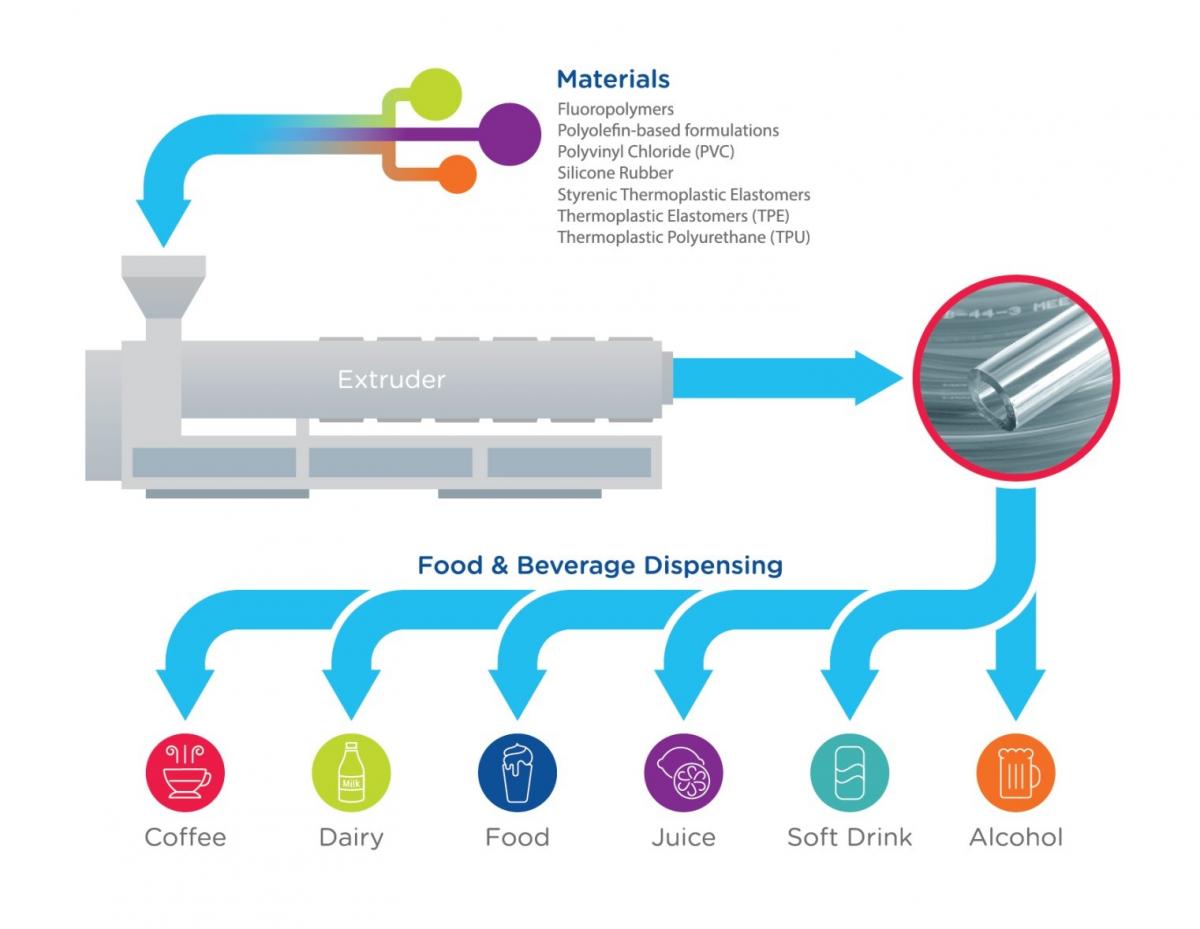

Dispensing tubing materials must be carefully selected based on criteria for the specific application to ensure the tubing performs well over its useful product lifecycle. Tubing solutions made from a variety of high-performance polymers and other enhanced materials can offer a wide range of attributes – making them ideally suited for various applications.

There is an appropriate dispensing tubing material for the type of food or beverage

Materials

There are several factors to consider when specifying dispensing tubing materials. For example, tubing designed specifically for use with solvents requires special properties in the inner bore to withstand negative effects to taste, odor and product purity caused by extraction from the tubing. Dispensing equipment that utilizes a pressurized pump to dispense the product requires a different material formulated to withstand higher pressure. Oftentimes a multi-material toolset is needed to deliver the best solution.

The list of materials used in food and beverage dispensing tubing as well as their key properties include:

Polyvinyl chloride (PVC)

This material can be used for aqueous foods, dairy and low alcohol (<10%) beverages but should not be used for products with high fat or alcohol content. PVC offers sealability, high flexibility, high clarity and some moderate resistance to pressure and cleaning chemicals, but may be prone to leaching, which may impact taste/odor. With the addition of an optimized formulation type and concentration, it can offer a long pump life (50-1000 hours).

>> Saint-Gobain’s Tygon B-44-3 is an example of PVC tubing.

Polyolefin-based formulations

This type of tubing can be used for aqueous foods, dairy and both low and high alcohol content (100%) products, but it should not be used for foods with high fat content. Polyolefin-based formulations have limited leachables and offer a high resistance to any impact on taste/odor. However, they usually do not withstand extended dynamic deformations associated with peristaltic pumping – resulting in pump life of 25-100 hours. Nevertheless, this material offers sealability, good flexibility and moderate resistance to pressure and cleaning chemicals. Clarity is typically good for this class of materials.

>> Tygon 2375 and Versilon 2001 are examples of polyolefin-based tubing.

Thermoplastic polyurethane (TPU)

Though suitable for fat and aqueous foods, dairy and low alcohol (<10%) products, these formulations should not be used for foods with high alcohol. Thermoplastic polyurethane tubing products offer sealability and good clarity as well as some resistance to pressure, but may impart some undesirable taste/odor if not designed properly. Likewise, its flexibility is determined by its material design.

>> Saint-Gobain’s Tygon B-44-FF is an example of TPU tubing.

Thermoplastic elastomers (TPE)

This material can be used for aqueous foods, dairy and low alcohol (<10%) beverages but should not be used for foods with fat or high alcohol content. TPV offer high flexibility, sealability and a long pump life (1000 hours); however, it has a low resistance to pressure and is opaque. The polymer also offers some resistance to cleaning chemicals but may have an adverse impact on taste/odor if not designed properly.

>> Tygon A-60-F is an example of TPV tubing.

Styrenic thermoplastic elastomers

Though nonpolar thermoplastic elastomers are suitable for aqueous foods, dairy and low alcohol (<10%) products, this polymer should not be used for foods with fat or high alcohol content. These materials offer sealability, high flexibility and a long pump life (500-1000 hours); however, it has low clarity and a low resistance to pressure. It also offers some resistance to cleaning chemicals.

>> Saint-Gobain’s Tygon XL-60 is an example of styrenic thermoplastic tubing.

Silicone rubber

This polymer should not be used for products with fat or high alcohol content, but is suitable for aqueous foods, low alcohol (<10%) and dairy products. Silicone rubber offers high flexibility and limited leachables resulting in limited impact on taste/odor; however, it offers no sealability, limited resistance to pressure or cleaning chemicals and possesses poor optical clarity attributes. Given its flexibility is can withstand moderate dynamic deformations associated with peristaltic pumping and offers 25-500 hours of pump life.

>> Tygon 3350TF and Versilon SPX-50 are examples of silicone rubber tubing.

Fluoropolymers

These materials are suitable for products with fat and high alcohol content as well as aqueous foods and dairy. Typically semi-rigid, fluoropolymers offer some limited flexibility and clarity, as well as high resistance to pressure and temperature, cleaning chemicals and leaching to offer a high resistance to any impact on taste/odor. They do not offer sealability.

>> Versilon FEP, Versilon PFA-F and Versilon PTFE-F are example of fluoropolymer tubing.

Saint-Gobain solutions

Though dispensing tubing solutions can go a long way in meeting performance objectives, not all OEMs or brand owners have the expertise or resources necessary to determine the best tubing solution for a dispensing application. Therefore, choosing the right supplier to provide high-performance and high-quality solutions will help ensure that the right food and beverage dispensing tubing is used for the right dispensing application.

Key is a tubing solutions supplier with comprehensive design capabilities and materials science know-how to help OEMs design high-performance dispensing equipment that not only also protects the consumer and the food and beverage brand’s integrity but also achieves reduced downtime and long-term cost-savings.

Saint-Gobain Performance Plastics, Process System’s mission is to assist customers through customization and co-developed fluid management solutions using our multi-materials expertise and comprehensive production capabilities. These capabilities include compounding (silicone and TPE to customize and optimize materials for specific properties, performance and applications), injection molding (silicone, 2K, micro, thermoplastic and fluoropolymer) and extrusion (single and multi-material/layered thermoplastic and fluoropolymer tubes and profiles).

Saint-Gobain’s food and beverage dispensing tubing solutions and products are designed to support critical performance requirements. With our extensive testing capabilities, R&D centers, application and regulatory compliance expertise and flexible, global manufacturing footprint – our customers can successfully address any challenges and achieve most any performance goals.

*JACKIE FIOCCA is a marketing specialist, Process Systems at Saint-Gobain Performance Plastics.

Kids Running Shoes