THE GLOBAL beer market was valued at USD530 billion in 2016. It is expected to reach USD 750 billion by 2022, growing at a CAGR of 6% between 2017 and 2022. The forecast comes from Zion Market Research, which reports the Asia Pacific region as accounting for the biggest share of the market in 2016. Meanwhile, global trends are forcing brewers elsewhere to rethink their strategies to boost growth.

Big help from AI

In Japan, Kirin Brewery will use artificial intelligence (AI) in beer-making which is mostly performed by professionals. According to a report in the Nikkei Asian Review, Kirin Holdings has partnered with the Mitsubishi Research Institute to make this automation scheme a reality.

The brewery has set its sights on a machine-learning program that can determine desired flavor, aroma, color, alcohol content, and then produce a recipe based on these – something that a brewer can perform well only after more than a decade of professional experience. The machine will discover beer formulas based on 20 years of test data. With AI, Kirin expects to cut product development, speed training, and enhance its efficiency.

Designed for SMEs

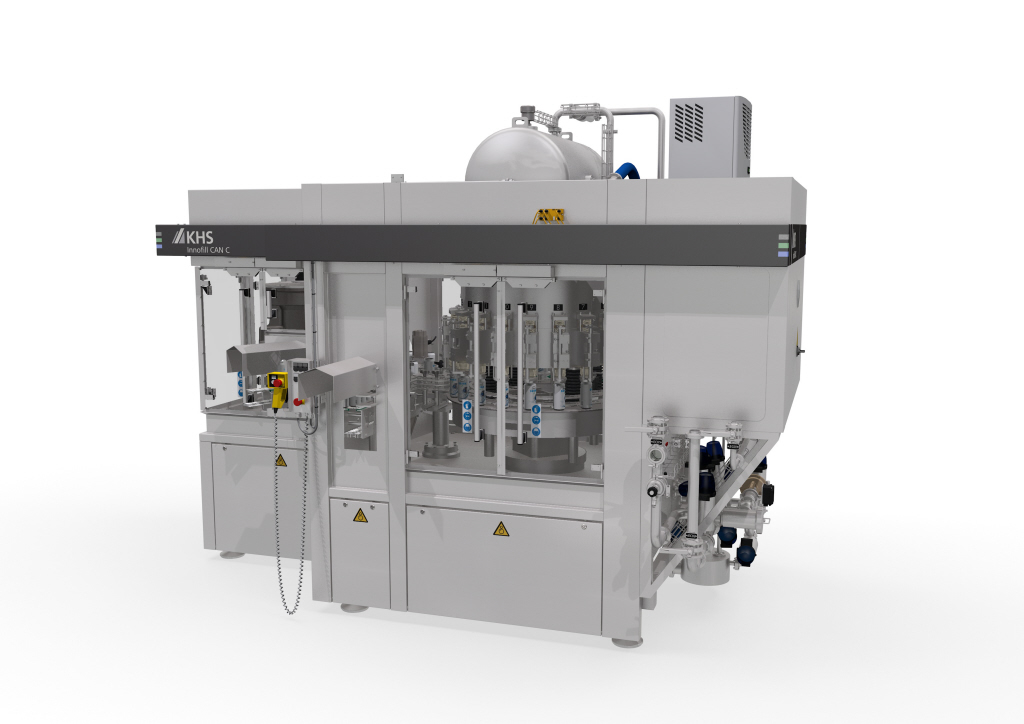

SMEs and craft-brewing companies don’t necessarily need big can fillers. For this market, KHS Group introduces a model for outputs ranging from 10,000 to 48,000 cans per hour.

The Innofill CAN combines a filler and seamer and is shipped to the customer as a complete machine in a single container and commissioned on site on a plug-and-produce basis without any need for complicated installation processes.

The hygienic design ensures there is no flavor carryover during changeovers. A gapless bell guide with PTFE expansion joints (Teflon) and bells are lifted and positioned fully electropneumatically to seal the cans – without any mechanical action from cams and rollers. This does away with the need for water lubrication, simplifies cleaning and promises a service life which is up to twice as long as before. PTFE materials are used in the filling valve, for example to seal the filling valve piston and in the gas membranes.

The new central product tank, which is installed at the top of the filler carousel and has a working volume of 50 to 200 liters, holds 300 liters less than the product tank on the big machines. Unlike in the latter plant technology, the tank does not rotate with the filler carousel on the Innofill CAN Compact. The beverage to be canned is supplied to the filling stations by a rotary distributor.

Electromagnetic inductive flow meters upstream of each filling valve permit exact filling volumes in the cans. The entire machine is very clearly structured and thus hygienic and easy to maintain.

The Innofill CAN from KHS is a filler and seamer that can be shipped directly to the customer in a single container

A tank cleaning machine for breweries

Scanjet Systems recently launched a new addition to their range of tank cleaning jets. The company which is an expert in advanced tank cleaning products and systems says its new Bio 25B is uniquely designed for the brewery process.

A tank cleaning jet usually sits inside a tank and is used to spray water or other cleaning liquids to clean the tank’s interior surfaces. Apart from this, the Bio 25B is also suited for the brewing process since it has the ability to run dry for short periods, to blow air or other gases into the brewing tanks. This function is useful in many ways, one of which is in blowing sterile air into the brewery fermentation tank to force out the CO2 in the tank before starting the cleaning process. This has the major benefit of avoiding chemical reaction of CO2 with cleaning agents, which would otherwise dilute the effectiveness of the detergents used and reduce the cleaning efficiency. Additionally, after the cleaning process is finished and before the new brewing cycle starts, the tank can be pressurised by blowing air into it through the Bio 25B.

To achieve the same functionality, a separate gas handling system is required, which presents its own operational and maintenance problems, not to mention extra cost. Using the Bio 25B can therefore reduce the financial investment as well as simplifying operations.

The Bio 25B was developed in collaboration with Handtmann Armaturenfabrik, a leading manufacturer of tank top plates for breweries.

Going for gluten-free beer

Most beers contain gluten, making it a no-no for people with celiac disease or on gluten-free diets. In patients with celiac disease, gluten can trigger the immune system to attack the small intestine, and to date there is no medical cure except to stay away from gluten. In beer, gluten comes from barley which is the usual grain for malting and brewing.

A recent study published in the Journal of Agricultural and Food Chemistry says that beers made with Witkop teff grains, a native to Ethiopia, may be a good alternative to brewed barley beers.

The gluten-free grain was tested by Valeria Sileoni and colleagues for its potential as a raw material for malting and brewing. In the process, the grains were steeped, germinated and dried, to determine the optimum conditions. Witkop teff took longer to malt than barley, and the team found that the teff had different enzymes to break down sugars than barley. The researchers concluded that Witkop teff grains have potential as a raw material for beer production but would likely require custom malting equipment on an industrial scale.

Associate Professor Liu Shao Quan (left) and Miss Chan Mei Zhi Alcine (right) from the Food Science and Technology Programme at NUS created a novel probiotic beer that boosts immunity and improves gut health.

Credit: National University of Singapore

Kind to the gut

Researchers from the National University of Singapore (NUS) made interesting headlines when they unveiled a specialty beer containing Lactobacillus paracasei L26, a probiotic strain that can neutralize toxins and viruses, and regulate the immune system. This first-ever beer infused with a functional ingredient was the idea of Chan Mei Zhi Alcine, a fourth-year student from the Food Science and Technology Programme under the NUS Faculty of Science, who spent nine months developing a recipe that would meet the standards of the International Scientific Association for Probiotics and Prebiotics, which recommends a minimum of 1 billion probiotics per serving in order to attain the maximum health benefits.

With Associate Professor Liu Shao Quan from the NUS Food Science and Technology Programme, Miss Chan conducted the production, first propagating the probiotic and yeast in pure cultures, and modifying conventional brewing and fermentation processes “For this beer, we used a lactic acid bacterium as a probiotic micro-organism. It will utilize sugars present in the wort to produce sour-tasting lactic acid, resulting in a beer with sharp and tart flavors. The final product, which takes around a month to brew, has an alcohol content of about 3.5%,” she said. The NUS research team has filed a patent to protect the recipe for brewing the probiotic sour beer.

Hombre