MANUFACTURERS looking to expand their share of the filled chocolate market are keen to explore new ingredients and efficient processes capable of giving consumers the exciting, moreish sensation they expect every time they eat a piece of snack. A good place to start that search is with the fat – around 30% of every filling is the filling fat, which has a key influence on the stability, melting properties, texture and flavor release.

Vegetable fats often hold the key to meeting consumer requests for new, indulgent products. One strong indulgence trend favors the special cooling sensation that gives filled chocolates a fresher feel and accentuates flavors – a sensation closely linked to the vegetable filling fat and influenced by the process, overall fat composition and the recipe as a whole.

At the same time, demand is growing for healthier products with a lower content of saturated fat per serving. This fat is an important structure builder, so developing a more indulgent, specialty filling with less saturated fat is a challenge. However, nothing is impossible provided that the optimal vegetable fat is identified.

The fats in the filling

Generally, 35% to 50% of a fat-based chocolate filling is a mixture of vegetable fat, milk fat, cocoa butter, nut oil and oils from other ingredients. While vegetable fat dominates the characteristics of the total fat phase, it is still influenced by the other fats that are present. This is why the choice of vegetable fat is so important to achieving the desired sensory quality, shelf life and process behavior.

For indulgent fillings, specialty fats can contribute stable aeration during processing, add an appealing melting profile and give impeccable bloom stability. They can also give a differentiating cooling effect. Specialty fats for healthier fillings must be free of trans fatty acids and non-hydrogenated. Equally important, they must enable a reduction in saturated fats without compromising the texture.

A cool sensation

Cool-melting filling fats belong to one of two triacylglycerol groups (TAGs):

I. A lauric-based oil made from palm kernel oil and/or coconut oil or their fractions, or

II. An oil blend dominated by symmetric monounsaturated triacylglycerols

Both groups are characterized by a high content of the same or similar melting TAGs. These interact with the rest of the fats in the recipe to form a narrow melting profile, which melts primarily below 30°C.

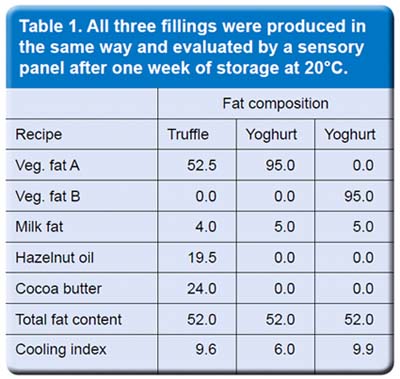

Table 1 shows the close connection between the fat phase and cooling sensation. The fat phase in the truffle recipe seems to have the right composition to obtain the fast melting properties that secure a high cooling sensation – a cooling index of 9.6. Here, vegetable fat A has been mixed with a high content of cocoa butter and diluted with nut oil. In the yoghurt recipe, however, vegetable fat A reduces the cooling sensation by around 35 %. When vegetable fat B is used instead of vegetable fat A, the cooling sensation in the same yoghurt recipe is recovered.

This clearly illustrates the importance of the vegetable fat in optimizing the cooling sensations.

Total fat impact The cooling sensation occurs when the fat melts and heats up from room temperature to body temperature. In the mouth, specialized sensory receptors – thermoreceptors – code absolute and relative changes in temperature. The faster the melting process and the more energy required, the more distinctive the cooling sensation experienced by the consumer. The total fat content at room temperature is, therefore, directly connected to the potential for a cooling sensation in the mouth, where the filling melts almost entirely.

The speed and ease with which a filling can be melted and manipulated in the mouth depends on the properties of the suspension. Low viscosity and, especially, a low yield value, created by the addition of polyglycerol polyricinoleate (PGPR), speed up the distribution of the filling in the mouth, increasing the surface area. This, in turn, increases the melting rate and the number of activated thermoreceptors.

Filling processing The final cooling sensation also depends on how the filling is cooled during processing, whether based on a group I or group II vegetable fat. The optimal cooling temperature of a group I fat is 5-10°C, while a group II fat is best cooled at 10-15°C. Because of the impact of the final fat composition, application and air velocity in the cooling tunnel, the optimal temperature must be evaluated for each application and filling. As group II fats are rich in polymorphic TAGs, they must be tempered or pre–crystallized before use. If not, they will crystallize in a lower polymorphic form and, consequently, transform to a higher form during storage, with a significant negative impact on the cooling sensation.

Lowering saturates

Altering the saturated fat without changing texture or melting properties is a very big challenge in the development of healthier confectionery products. It is important to look beyond the saturated fatty acid content of the vegetable fat to the saturated fats in the entire fat phase. Maintaining all the characteristics of a filling is very difficult if the fat composition undergoes considerable change.

Opportunities for altering the total fat composition include:

1. Adjusting the ratio between different components, for example by incorporating more wafer, nuts and filling and using less coating

2. Replacing fats from ingredients and substituting with a vegetable fat, giving more structure for each % of saturated fatty acid

3. Slightly lowering the total fat content

4. Replacing the vegetable fat with another that contains less saturated fat but has the same texture.

In most cases, the best approach is to start by optimizing the first three points. This will ensure that the final solution is closer to the original product in terms of taste and production settings.

It will also maximize the reduction in saturated fat.

Fats with different textures Different fats produce different textures, even though their content of saturated fat is the same. This is important to bear in mind when reducing saturated fats. A main influencing factor is the chain length of the fatty acids – a shorter chain length has a lower melting point. One example is milk fat which, despite its content of saturated fat, contributes very little structure.

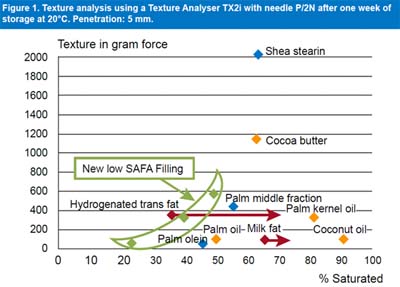

Figure1 shows how texture can vary from fat to fat. All measurements are based on the same filling recipe with the same particle size and the optimal process for each fat system. The only variant is the type of fat used.

The two red points indicate the presence of trans fatty acids. These produce a texture similar to saturated fats and, consequently, much higher than indicated by their saturated fat content.

The three green points are all examples of low saturated filling fats, where the target is to maximize the texture obtained from the saturated fat. These vary from very soft to semi-hard, covering most of the existing filling range today. They are all non-hydrogenated and do not require tempering, making them easy to use.

The four yellow points are examples of well-known confectionery fats, while the three blue points show three fractions of well-known fats.

25% reduction in saturates These texture analyses correlate perfectly with the findings of a sensory panel regarding filling hardness, whereas the correlation with solid fat content varies from fat to fat.

They also show that it is possible to cut saturated fats by 25% by switching from milk fat to palm oil, for example, without any significant change in texture at 20°C. An even higher reduction can be achieved by replacing milk fat with one of the new low saturated fats.

Fat interactions A typical filling comprises several fats which interact in different ways. One well-known example is the combination of lauric fat and cocoa butter. Although the content of saturated fat is unchanged when the two fats are mixed, the incompatibility of the two fats makes the mixture much softer.

Such fat interactions are important to consider when developing new low saturated fillings. The compatibility of vegetable fats with milk fat and cocoa butter is particularly important because of the wide use of these fats in filling recipes.

New opportunities

Optimizing a filling is easier said than done. But when it is done right, there are many opportunities to bring new, exciting products to the market – in line with today’s trends. Choosing the right vegetable filling fat is the first step towards a fresh, cool-melting filling or a healthier filling reduced in saturated fat. With the appearance of new vegetable fat solutions, it has become possible to produce new indulgent fillings that overcome texture challenges with comparative ease.

* Bjarne Juul is Product & Technology specialist at AAK, the world's largest supplier of specialty fats to the chocolate and confectionery industry

Air Jordan XX9 Low