Spot welding inspection robot (ultrasound inspection probe)

Find out how Toshiba's recent development of a system allows testing to be carried out automatically by robots in a non-destructive manner, and is poised to spark a massive revolution in manufacturing in the automotive industry.

The Move Towards Smart, Automated and Non-Destructive Inspection

As cars become lighter and stronger in recent years, high-strength steel sheets known as 'high-tension materials' are increasingly being used. The properties of these high-tension materials make it hard for chisels to be inserted and returned to normal once they are deformed. The welded spots are often destroyed in the course of inspection.

Tapping on technology for medical use and power generation plants, Toshiba developed an ultrasonic testing device known as Matrixeye™, the world's first 3D SAFT (Synthetic Aperture Focusing technique) inspection equipment with phased array function. Matrixeye™ allows welds to be inspected non-destructively and inspection to be performed automatically by robots.

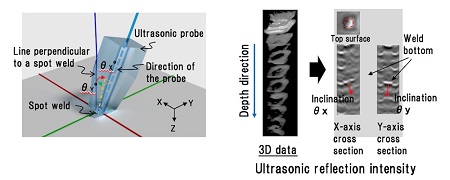

The challenge in non-destructive inspection technology was creating structures for automating spot welding inspections through robot control. The tilt estimation engine is a new technology that automatically adjusts the measurement angle of the inspection probe. Based on the ultrasound reflection data measured by the Matrixeye™, it estimates the tilt of the welded part and then a robot automatically corrects the angle of the inspection probe. Through this, inspection time is shrunk from 30-40 seconds for human beings to approximately 7 seconds.

As the concept of Mobility-as-a-Service (MaaS) develops in the future, the number of public vehicles will most likely increase as well. To support this coming era, factories will be expected to put structures in place to enable them to provide high-quality vehicles in a speedy fashion. Toshiba is carrying out verification tests with a goal of launching this spot welding inspection technology within a year, and for the technology to be adopted in other fields of manufacturing too.

Spot welding inspection robot (ultrasound inspection probe)

Automatic tilt adjustment

From left to right: Akira Ushijima, Masahiro Saito, Yasunori Chiba and Hiromasa Takahashi, members of the spot welding inspection robot development team of the Mechatronics Engineering Solution Department, Corporate Manufacturing Engineering Center, Toshiba Corporation.

Adidas Adilette Slides