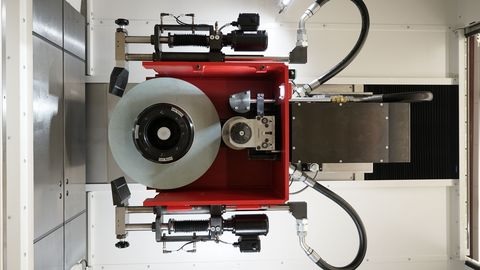

Industry projections point to upcoming growth in the light and heavy-vehicle sectors, along with oil and gas extraction, mining, medical equipment and supplies, and civilian aircraft, all of which can offer profit-expansion opportunities for shops. The BLOHM PROFIMAT XT heavy-duty continuous dress creep feed grinder from UNITED GRINDING makes an ideal addition to the production of parts for these industries. For components such as vehicle hydraulic pumps and steering racks, gas turbine blades and shrouds, knee joints, bone saws, knives, punches, hirth couplings and more, the machine combines outstanding rigidity and power with fast axis speeds for exceptional grinding productivity, especially on parts that require burr-free results on high depths of cut, all without constant tool replacements.

For such components, the machine’s table speeds of over 1500 in/min, (38,100 mm/min), along with a quick changeover wheel-dresser system and enhanced acceleration/deceleration rates, translate to optimal positioning speeds and short cycle times. Optional features include table dresser systems, HSK wheel flanges and a linear drive table to produce reciprocal grinding speeds up to 3,000 in/min (76,200 mm/min) for fine surface finishes. Additional grinding advances include dual left and right coolant nozzles with the RazorTec® wheel cleaning system.

The machine is available in five sizes, with grinding ranges from 15.75" x 31.5" (400 x 800) to 23.62" x 78.74" (600 x 2000 mm). With spindle power up to 84 hp (62 kW) and 8000 rpm, and grinding wheels up to 20" (500 mm) diameters and 6" (160 mm) widths, the BLOHM PROFIMAT XT excels at machining large parts with high stock-removal requirements. The machine can accommodate maximum workpiece weights of 1764 lbs (800 kg) on a 31.4" x 23.6" (800 x 600 mm) table. For improved stiffness, the BLOHM PROFIMAT XT incorporates a ribbed base and column casting with dual ballscrews for Z-axis cross-grinding stability.

The machine is equipped with a Siemens SINUMERIK 840D sl control that features a touch screen monitor and Windows-based graphical user interface. UNITED GRINDING customized this advanced human-machine interface (HMI) to provide grinding process data, machine health monitoring, operational efficiency and graphical product information.