The decision on how to embark on or expand a smart factory initiative should align with the specific needs of an organization. The reasons that companies embark or expand on the smart factory journey are often varied and cannot be easily generalized. However, undertaking a smart factory journey generally addresses such broad categories as asset efficiency, quality, costs, safety, and sustainability. These categories, among others, may yield benefits that ultimately result in increased speed to market; improved ability to capture market share; and better profitability, product quality, and labor force stability. Regardless of the business drivers, the ability to demonstrate how the investment in a smart factory provides value is important to the adoption and incremental investment required to sustain the smart factory journey.

Asset efficiency

Every aspect of the smart factory generates reams of data that, through continuous analysis, reveal asset performance issues that can require some kind of corrective optimization. Indeed, such selfcorrection is what distinguishes the smart factory from traditional automation, which can yield greater overall asset efficiency, one of the most salient benefits of a smart factory. Asset efficiency should translate into lower asset downtime, optimized capacity, and reduced changeover time, among other potential benefits.

Quality

The self-optimization that is characteristic of the smart factory can predict and detect quality defect trends sooner and can help to identify discrete human, machine, or environmental causes of poor quality. This could lower scrap rates and lead times, and increase fill rates and yield. A more optimized quality process could lead to a better-quality product with fewer defects and recalls.

Lower cost

Optimized processes traditionally lead to more cost-efficient processes—those with more predictable inventory requirements, more effective hiring and staffing decisions, as well as reduced process and operations variability. A better-quality process could also mean an integrated view of the supply network with rapid, no-latency responses to sourcing needs—thus lowering costs further. And because a better-quality process also may mean a better-quality product, it could also mean lowered warranty and maintenance costs.

Safety and sustainability

The smart factory can also impart real benefits around labor wellness and environmental sustainability. The types of operational efficiencies that a smart factory can provide may result in a smaller environmental footprint than a conventional manufacturing process, with greater environmental sustainability overall.25 Greater process autonomy may provide for less potential for human error, including industrial accidents that cause injury.26 The smart factory’s relative self-sufficiency will likely replace certain roles that require repetitive and fatiguing activities. However, the role of the human worker in a smart factory environment may take on greater levels of judgment and on-the-spot discretion, which can lead to greater job satisfaction and a reduction in turnover.

Impacts of the smart factory on manufacturing processes

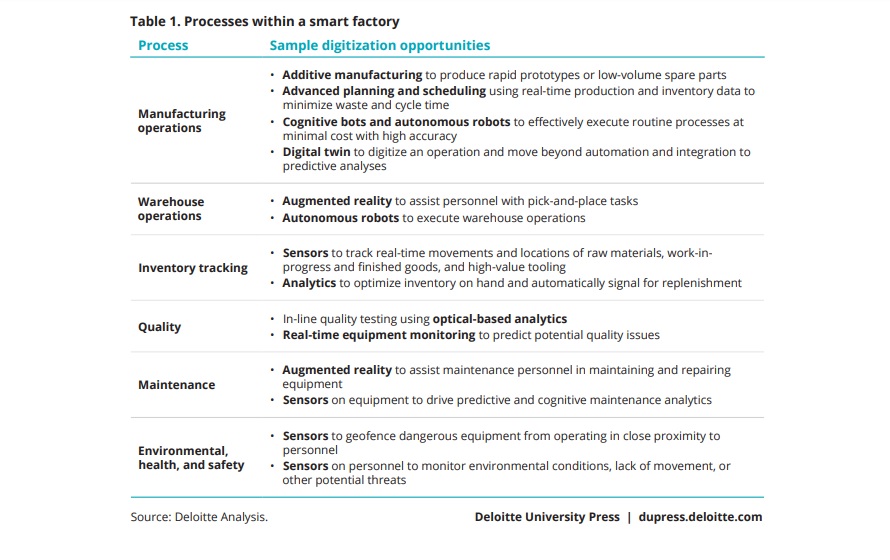

Manufacturers can implement the smart factory in many different ways—both inside and outside the four walls of the factory—and reconfigure it to adjust as existing priorities change or new ones emerge.28 In fact, one of the most important features of the smart factory—agility—also presents manufacturers with multiple options to leverage digital and physical technologies depending on their specific needs. The specific impacts of the smart factory on manufacturing processes will likely be different for each organization. Deloitte has identified a set of advanced technologies that typically facilitate the flows of information and movement between the physical and digital worlds.29 These technologies power the digital supply network and, by extension, the smart factory—creating new opportunities to digitize production processes. Table 1 depicts a series of core smart factory production processes along with a series of sample opportunities for digitization enabled by various digital and physical technologies.

The smart factory

It is important to note that these opportunities are not mutually exclusive. Organizations can—and likely will—pursue multiple digitization opportunities within each production process. They may also phase capabilities in and out as needed, in keeping with the flexible and reconfigurable nature of the smart factory.

It is important for manufacturers to understand how they intend to compete and align their digitization and smart factory investments accordingly. For example, some manufacturers could decide to compete via speed, quality, and cost, and may invest in smart factory capabilities to bring new products (and product changes) to market faster, increase quality, and reduce per-unit costs. Others may choose to focus on “lot size of one” product customization and fulfillment models, and invest in other technologies to fulfill those goals.