To expand sustainable production, west African blown film manufacturer Asahel Benin Sarl.

has ordered a second Coperion compounding system specifically for manufacturing bio-based

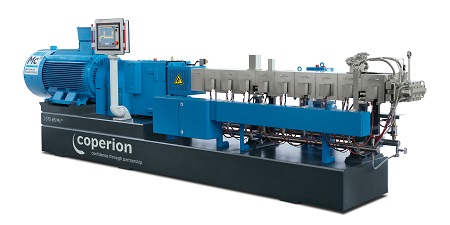

compounds. This system, built around an STS 65 Mc11 twin screw extruder with side feeder, includes four Coperion K-Tron feeders for high-accuracy feeding of powders, pellets and liquids, as well as an SP 220 treasure strand pelletizer with a water bath and an air wipe.

This new compounding equipment serves to expand upon Asahel Benin’s pilot system from Coperion which the company has successfully used to manufacture biocompounds since Benin’s July 2018 prohibition of plastic bags and packaging.

Asahel Benin processes these biocompounds on its blown film machines into biodegradable bags and packaging, making the company a pioneer among west African manufacturers of more environmentally friendly short-life plastic products.

The new STS 65 Mc11 extruder and its peripheral equipment are currently being installed on site. Asahel Benin will begin production on this machine in spring 2021.

Biocompounds production enhanced

Coperion designed Asahel Benin’s compounding machine to be very flexible in order to achieve maximum freedom in the production of biocompounds. For example, thanks to the highly accurate Coperion K-Tron feeders, the system can handle a variety of raw materials, depending on the recipe.

The four loss-in-weight feeders include two T35 twin screw feeders, one S60 single screw feeder as well as a liquid feeder.

While the S60 single screw feeder offers an optimal delivery of free-flowing materials such as base resin pellets or granulates, the self-cleaning action of the T35 twin screw feeders makes them ideal for feeding particularly difficult powder additives, such as starch or calcium carbonate. Both T35 twin screw feeders are equipped with Coperion K-Tron’s unique ActiFlow™ smart bulk solid activator which reliably prevents the formation of material bridges or ratholes in the hopper. All four feeders are mounted on platform scales which feature patented Smart Force Transducer (SFT) single wire weighing technology. These scales provide accurate, stable and reliable digital load measurement under a broad range of operating conditions. Together with the fast sampling rate of the KCMIII feeder controller this advanced weighing technology results in extremely high short-term accuracy, which is particularly important in continuous extrusion processes.

The biodegradable polymers are melted in the process section of the STS 65 Mc11 extruder, and non-meltable components, such as starch, are plasticized. Intensive dispersion and devolatilisation of the melt results. After passing through the die head and nozzle the extrudate goes through a water bath for strand cooling, the strand surfaces are then dried using an air The STS 65 MC11 twin screw extruder from Coperion Access Code wipe, and the compound is finally pelletised in an SP 220 treasure strand pelletiser.

Coperion ensured that all of the product-contact machine parts have high wear protection, further

increasing operational flexibility.

Asahel Benin will be able to process various raw materials, even highly corrosive andabrasiveones, on this compounding system for many years to come.

Sustainable corporate strategy

Since 2018, the import, household products and in shopping bags for supermarkets. The new law was at once both a challenge and an opportunity for Asahel Benin. The company switched its production completely to bio-based plastics. Following a successful test and training phase at Coperion’s Test Lab in Stuttgart, Asahel Benin Sarl. began manufacturing biodegradable compounds using a laboratory system built around a ZSK 26 Mc18 in its home country. The company then processes these materials into biodegradable bags and packaging on its blown film machines.

Increased throughput

With its investment in another Coperion compounding system, Asahel Benin will significantly increase its production capacity. David Romaric Tinkou, Head of Development at Asahel Benin Sarl., is very satisfied with his company’s strategy: “We have succeeded in completely converting our production to the manufacture and processing of biodegradable compounds. Thanks in no small measure to the reliable technology and process engineering support from Coperion, today we are successfully combining high production technological demands and environmental compatibility. We will continue to follow this sustainable course and we look forward to being able to expand our production capacity significantly with this new compounding system in the near future.”

production, sale, and possession of petroleum-based plastic bags and packaging has been banned in Benin. Prior to that time, Asahel Benin Sarl. had used both new PE pellets as well as recyclates for manufacturing the films that were then used predominantly in Wi th i t s specifi c torque of 11.3 Nm/cm3 STS Mc11 compounders sets new standards: it features up to 27% higher throughput rates than the preceding model, while the higher degree of screw fill results in a decrease of melt temperature, thus improving compound quality. It incorporates the full process and quality know-how of Coperion.

The STS Mc11 series is exclusively equipped with European, Coperion branded gearboxes. Maximum screw speed has been increased from 800 to 900 rpm. To improve cleaning and facilitate quick changeovers for masterbatch applications, the STS twin screw extruder also features hoppers with inserts and a redesigned die head. The screw shaft coupling is similar to the one long proven in the ZSK Mc18 series. The optimised base frame withstands torsion under maximum stress. The STS Mc11 compounder covers most standard applications in process technology. It offers high productivity at an attractive price-performance ratio. Production of the STS Mc11 is in Nanjing, China, in compliance with CE directives. The result: A high-performance compounding system with low investment costs which ensures a fast return on investment. The modular design of the process section allows maximum flexibility in production at process lengths of 24 to 68 D.

For the Non-European market Coperion has designed a STS Mc11 two-stage compounding system specifically for the production of temperature and shear sensitive plastics.

This two-stage processing system with the STS Mc11 twin screw extruder and a single discharge screw ensures both high product quality and maximum economic efficiency in the processing of PVC, cables and special compounds. Thanks to Coperion’s high standard manufacturing know-how this two-stage compounding system ensures consistency and repeatability of product quality, high throughput rates, more rentability and flexibility.

Coperion is the international market and technology leader in compounding and extrusion systems, feeding and weighing technology, bulk materials handling systems and services.

Coperion designs, develops, manufactures and maintains systems, machines and components for the plastics, chemicals, pharmaceutical, food and minerals industries. Within its three divisions – Polymer, Equipment & Systems, and Service – Coperion has 2,500 employees and nearly 30 sales and service companies worldwide. Coperion K-Tron is part of the Equipment & Systems division of Coperion.