The plastic pipes industry continues to grow despite the impact of Covid-19 on economies around the world. As the global market moves to recover from the pandemic, the plastic pipes market is projected to grow by $8.2 billion, at a compounded annual growth rate (CAGR) of 3.5% during the period 2020-2025, according to a report by ResearchAndMarkets.com.

PVC, one of the segments analysed in this report on the global pipes market, is forecast to grow at over 4.4% yearly to reach a market size of $14.5 billion by the end of the period. As the global economy moves to recover from the detrimental effects of the coronavirus pandemic that have impacted industrial production, the PVC market will be reset to a new normal which going forward in a post COVID-19 era will be continuously redefined and redesigned, according to the report. Staying on top of trends and accurate analysis is paramount now more than ever to manage uncertainty, change and continuously adapt to new and evolving market conditions.

As part of the new emerging geographic scenario, the United States is forecast to readjust to a 2.2% CAGR. In Europe, Germany will add over $198.5 million to the region's size over the next 7 to 8 years. In addition, over $200.8 million worth of projected demand in the region will come from the rest of the European markets. In Japan, the PVC segment will reach a market size of $604.7 million by the close of the analysis period.

Amid the growing push for decoupling and economic distancing, the changing relationship between China and the rest of the world will influence competition and opportunities in the plastic pipes market, according to the report. Against this backdrop and the changing geopolitical, business and consumer sentiments, the world's second largest economy will grow at 6.9% over the next couple of years and add approximately $2.7 billion in terms of addressable market opportunity.

But what defines the pipes market in the post-pandemic screnario is the preference for efficient and cost-saving solutions, especially in the production of large diameter pipes. Recent innovations point towards solutions for high volume output and reliable performance.

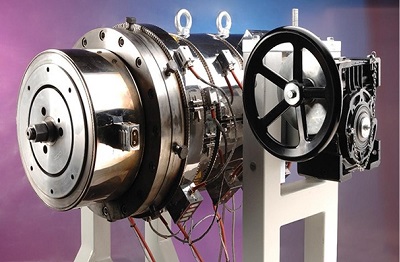

Complete pipe extrusion line

Aiming at a larger share of the equipment market for extruded PVC and polyolefin plastic pipe, Conair introduces a cost-effective solution for processing extruded plastic pipe over 2 feet in diameter. The PipeMaster™ is a complete line of downstream processing equipment and tooling that offers rugged, reliable, and cost-efficient performance in six size ranges for pipe diameters from 0.4 to 24.9 inches (10 to 630 mm) in up to 5-layer construction.

The line represents a big change for Conair, whose range of pipe processing equipment has, until now, served sizes of 8 in (200 mm) or less, says Ernie Preiato, Vice President, Extrusion for Conair and a 33-year veteran of the extrusion field. “We understand that extruded pipe processors compete in a very robust and cost-conscious market and can choose equipment from all over the world, with various levels of quality and price points. Our feedback from processors was that they wanted a reliable U.S. source for equipment that delivers high-end quality, output, service and support, but without the huge price tag.”

Mr. Preiato explains that the key to Conair’s new, competitively priced PipeMaster line is found in its simplicity and attention to the fundamental needs of processors: “This equipment – spray tanks, puller/haul-off units, saw cutters, and drop-off tables – combines very rugged construction with simple, but well-engineered controls. It is complemented by an extensive range of the extruder tooling, including pipe dies and calibration sleeves, that most processors need but often have difficulty finding or building at a competitive price. And, the entire PipeMaster line is backed by Conair’s factory service and support.”

The PipeMaster line includes monolayer and multilayer pipe extrusion dies optimised to different material types (PE/PP, PVC and others), and for pipe diameter ranges of 2.5, 4.3, 6.2, 9.8, 15.7 and 24.9 in (63, 110, 160, 250, 400 and 630mm). Each die is mounted on a movable, height-adjustable stand and features polished, heat-treated internal surfaces. Interchangeable die pins and nozzles allow dies to produce multiple sizes of pipe. Multilayer extrusion dies can extrude up to five layers in a single pipe. The machine’s output rates range from 550 to 3520 lb/hr (250 to 1600kgs/hr) and it comes with a full range of pipe calibration tools, with options for dry sizing or water-ring cooling and sizing.

Vacuum immersion, vacuum-spray, or immersion-only cooling tanks with single or dual chambers are integrated. All tanks feature 304 stainless steel construction on internal/wetted surfaces, durable painted-steel exterior surfaces, simple frame-mounted controls and fully-adjustable stands. Cleated puller/haul-off units that automatically synchronise speed with extruder screw speed control and integrate with gravimetric material dosing for stable production and consistent pipe unit weight. Inside each puller’s fully-enclosed safety cabinet, brushless AC vector motors provide steady pulling force using soft, non-marking cleated pads. Also included are servo-driven pipe cutting units, also synchronised to line speed, which measure and cut pipe in a variety of lengths to meet application requirements. Multiple cutter types accommodate different pipe sizes and application requirements, including rotating disc cutters for chipless displacement cuts and planetary cutters for milled or chamfered cuts. It also features pneumatically operated pipe tilting/dump off tables synchronise with line speed to receive and automatically dump finished pipe lengths into stacks for easy removal, packaging, shipment or storage.

According to Mr. Preiato, Conair is building a new 6-inch plastic pipe extrusion line at its extrusion laboratory and pilot plant in Pinconning, Michigan, and plans a live demonstration of the new line and its PipeMaster downstream processing equipment in early June. Conair will also highlight PipeMaster equipment at a customer open house in Pinconning later in 2021.