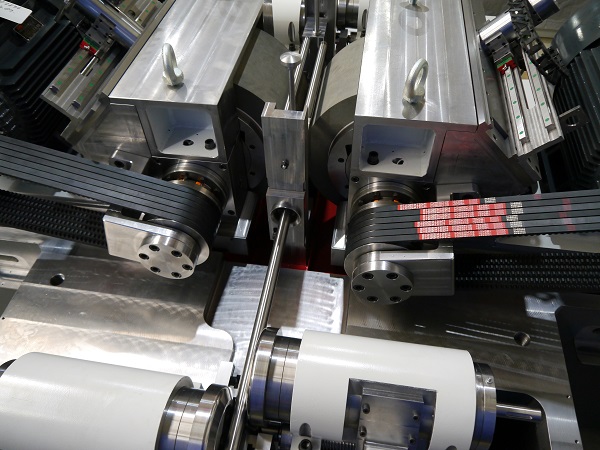

The pull-in gripper moving by a ball screw is pulling in the wire, which is then taken over by the chaintrack drawing system.

At WIRE 2022, EJP will introduce three new developments that make the production of bars and tubes easier and more efficient. The new 12.5 ton chaintrack drawing unit now makes it possible to draw products with sensitive surfaces at even higher speeds. With its new center less grinding machine, EJP increases precision and flexibility of bar grinding. And, finally, the new-generation laser-optical straightness measuring system for bars enables optimization of the two-roll straightener in an inline process.

New: Higher productivity when drawing wire and tubes

Before now, drawing lines using a chaintrack unit, instead of the traditional drawing method based on drawing cams and drawing carriages, have usually been built for drawing forces of up to 2.5 tons, up to 10-mm-dia. materials and maximum drawing speeds of 250 m/min.

At the trade fair, EJP will, for the very first time, introduce a chaintrack unit for drawing lines with a drawing force of up to 12.5 tons for starting material up to 28 mm in diameter. The machine is a further development of the patented solution by EJP. Compared to the two-carriage principle, it has the advantage of working at a very even speed throughout the entire drawing process. This results in a significant increase in productivity, especially for stainless steel.

In contrast to conventional systems, the new machines can now also be used for finished material or pre-drawing copper tube because, despite the high drawing force, they process the material very gently. No pressure is applied to the chains of the chaintrack unit because the drawing is decoupled from the opening and closing of the drawing jaws. As the jaws always run parallel to the direction the material is moving in, they protect the surface of the wire or tube.

The new design also means that significantly less tool changing is required for material dimension changes.

New: Solutions for the entire process

At WIRE 2022, EJP will also present a center less grinding machine for bars for the first time. This means that the company now offers solutions for the entire process from a single source: From drawing to peeling and straightening to grinding.

The new machine, which was developed from the ground up, has four powered polishing discs. In contrast to conventional systems, the relationship between the feed rate and speed of the bar during ongoing operation can be changed at the push of a button. Because of this, production does not have to be stopped – as was previously the case – to adjust the height of the guide lineals of the polishing discs. The result: Less downtime and a higher throughput overall.

New: Straightness measurement with feedback to the process

In collaboration with the Italian producer of measurement systems, Q-Tech, EJP has developed the second generation, laser-optical 3D straightness measurement system, TQC 2.0. What is new is that bars with diameters down to 5 mm can now also be measured.

Furthermore, it not only measures the straightness of thin bars and tubes but also saves the measurement data on a server. These form the basis for the optimum setting of the two-roll-straightening machine virtually in real time.

The system measures both straightness overall as well as individual, freely definable reference lengths. This allows bars that do not meet the specifications of the client to be identified and graded or sorted out. Using linear transducers to detect the position of the bar, EJP achieves a higher measurement accuracy compared to other systems.

With the driven polishing discs (below), the ratio between feed and speed of the bar can be changed during operation.