ExxonMobil has commercialised Exceed™ S performance polyethylene (PE) resins, which deliver industry leading combinations of stiffness and toughness while being easy to process. Utilising the company's latest innovations in polymer science, the new PE platform provides opportunities to reduce the complexity of film formulations and designs while improving film performance, conversion efficiency, and packaging durability versus current market references.

Modern film design is a story of increasing complexity and compromise between performance and processability that is accepted to ensure durable packaging and high customer satisfaction. Multi-component resin blends in coextruded and laminated films with high layer counts are common-place. Every step of producing and converting printed film into durable packaging is prone to complexity-induced inefficiency, scrap and human mistakes. What if your resin could help simplify all of this?

“Exceed™ S performance PE resins deliver simplicity without compromise,” said Tom Miller, Exceed™ S Marketing Manager, ExxonMobil. “Now converters can get high performance with easy processing, stiffness and toughness with less blending, and resin solutions that can simplify operations and improve package durability. It is a platform of performance polyethylene grades designed to do so much, so simply.”

Innovative converters can rethink film design by: utilising Exceed™ S functional layers to maximise performance; leveraging increased performance to help facilitate solutions with sustainability benefits; reducing the need to add HDPE for stiffness or LDPE for easy processing; creating flatter, less extensible films to increase print and package line efficiency; and delivering more durable flexible packaging contributing to consumer satisfaction and helping to reduce food waste.

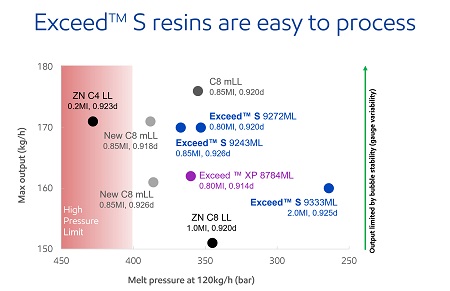

The first three commercially available grades are designed to ensure low melt pressure and high output on blown film lines. The combined benefits of Exceed™ S resins allow the creation of a broad range of packaging and film applications.

Large format heavy duty sacks used in industry and agriculture along with silo bags for farming benefit from increased puncture, impact and tear resistance. The resin’s combination of low melt pressure and high extrusion output can help increase converter’s production capacity.

In primary packaging, non-laminated coextruded films used in pouches and bags containing liquid, food, or other goods can benefit from improved toughness and are less likely to break when transported or dropped. Multi-wall bladders used in hot-filled bag-in-box packaging exhibit exceptional resistance to heat-induced blocking and flex cracking.

PE//PE laminates with improved stiffness, toughness and bag drop survival help facilitate larger pouch sizes and accommodate more aggressive contents, helping to expand market usage of mechanically recyclable packaging.

In these types of applications, the outstanding mechanical properties of Exceed™ S resins can be used to increase film performance, maintain comparable performance at a thinner gauge, produce more durable mono-material products, or incorporate high percentages of recycled content. Providing such solutions are a focus within ExxonMobil’s four-pronged approach of using performance polymers to help facilitate solutions with sustainability benefits.

“ExxonMobil has been at the forefront of polyethylene innovation for nearly thirty years. The new Exceed™ S platform embodies our most advanced product and process development informed by deep, long-standing partnerships with our customers,” said David Hergenrether, Vice President Polyethylene, ExxonMobil. “The innovation opportunities that Exceed™ S performance polyethylene offers has already resulted in successful collaborations with over 75 customers globally working on over 100 different applications. We look forward to collaborating with our customers on new opportunities to advance their products.”

To learn more about how ExxonMobil’s Exceed™ S solutions can help converters rethink and simplify film design, please visit: https://www.exxonmobilchemical.com/en/products/pe