2020 could be remembered as a transformative year for electric cars. It’s difficult to ignore Covid-19 and its societal effects. As various economies around the world rush to contain the spread of the pandemic, it has become apparent that the global automotive industry has been significantly affected, especially the development of electric vehicles (EV). Despite the setback, the EV industry has been rising above the grim scenario as the global demand for electric vehicles is projected to rise from US$ 121.8 billion in 2020 to US$ 236.3 billion in 2027, to post a CAGR of 10.6%, according to a report by Bluewave Consulting. A McKinsey report estimates 130 million EVs on the road by 2030.

According to IHS Markit, global sales of battery electric vehicles (BEVs) and other electric vehicles (EVs) is estimated at 2.5 million in 2020, rising by around 70% by 2021. By far the highest market shares will be held by China and Europe in 2021, with China accounting for approximately 44% and Europe for about 28%. North America, with a 16% share, and Japan and South Korea, with an 11% share, are in second and third place, respectively.

Solar roof as future trends

The move to utilise solar roof for automotive application has gained ground. Teijin Limited and its joint development partner Applied Electric Vehicles (Applied EV) have developed a polycarbonate solar roof for future mobility applications.The green solution marks another major step towards the companies’ shared vision of zero-emission mobility.

The new solar roof uses Teijin’s Panlite® polycarbonate resin glazing for its surface. Teijin used its proprietary knowhow in polycarbonate resin glazing and technologies to integrally mould the roof’s curved surface into an ideal shape, an extremely challenging process in the case of using

glass. Not only is the Panlite® glazing roof ideally shaped, it achieves the strength and rigidity required for the vehicle roof.

Conventional polycarbonate resin offers excellent impact resistance, but it must be specially processed to realise the level of weather resistance needed for long-term outdoor use. Teijin’s Panlite® glazing, however, can easily be given a proprietary hard coating to achieve the 10-year weather durability required for automobiles.

Tei j in and Appl ied EV deployed the solar roof on a prototype EV passenger pod that was installed on the Blanc Robot - a zero-emission robotic vehicle platform developed by Applied EV using materials and technical support from Teijin. In testing conducted by Applied EV in Australia,

the solar cells mounted on the Panlite® roof achieved output of about 330W, which is equivalent to a conventional solar panel housed under glass.

Because the vehi c le i s l ight and ver y energy efficient, the benefits of solar charging the Blanc Robot are much greater than the results that can be achieved on a typical EV. Applied EV tests suggest that the solar array can contribute up to 30% of the vehicle’s energy budget in ideal conditions and around 15-20% on a typical day. Under the right conditions, this could extend vehicle range for the Blanc Robot by between 30 and 55 kilometres compared to the same vehicle without a Panlite® roof.

Teijin and Applied EV continue to collaborate on the use Teijin’s various material technologies in the development of further EV components, including structural elements, glazing and exterior body panels, with the intention of commencing high volume production in the latter half of 2022.

The field of mobility is undergoing a significant transformation propelled by new concepts such as

connected, autonomous, shared and electric (CASE) vehicles and Mobility as a Service (MaaS). Electrification and autonomous technologies are rapidly being developed for next-generation mobilities that will reduce environmental impact and address new needs in society, such as transportation for aging societies. Teijin and Applied EV, who commenced their joint-development in 2019, are committed to establishing a technological foundation to support practical multipurpose zero-emission vehicles for future society. As Julian Broadbent, CEO of Applied EV, explained: “Carbon reduction and energy efficiency is central to our design philosophy. Businesses around the world are seeking ways to reduce their carbon footprint from transport. Our collaboration with Teijin is helping Applied EV to reduce the energy used per transport mile and also increase the proportion of energy that is sourced from renewables, which is good for business and good for the environment. Now that we have proven the technology on a passenger EV, it is easy for us to roll out solar charging for a range of other vehicle types.”

“Through our collaboration with Applied EV, we are addressing strong demands in society by applying our advanced materials and structural-design knowhow in innovative solutions for next-generation EVs,” said Toshiaki Hotaka, General Manager, Mobility Division of Teijin Limited.

“Aiming to become a company that supports the society of the future, we have positioned environmental-value solutions as priority field in which Teijin can contribute to circular economies and sustainability.”

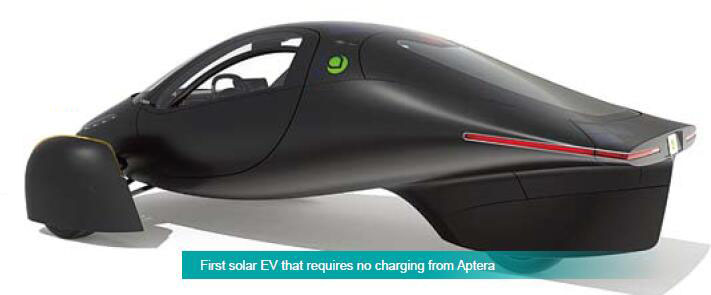

First never charge solar vehicle

Aptera Motors has introduced the first solar electric vehicle (sEV) that requires no charging for most daily use and boasts a range of up to 1,000 miles per full charge, shattering industry performance achievements to date. Aptera leverages breakthroughs in lightweight structures, low-drag aerodynamics and cooling, material science, and manufacturing processes to deliver the most efficient vehicle ever made available to consumers.

The solar cells mounted on the Panlite® roof achieved output of about 330W. “With Aptera’s Never Charge technology, you are driven by the power of the sun. Our built-in solar array keeps your battery pack topped off and anywhere you want to go, you just go,” says Co-Founder Chris Anthony. Never Charge is built into every Aptera and is designed to harvest enough sunlight to travel over 11,000 miles per year in most regions. The Aptera vehicle is made of lightweight composites that are many times stronger than steel, allowing its unique body shape to slip through the air with an unheard-of drag coefficient (Cd) of .13.

Aptera key breakthroughs and features include a recordbreaking range where Aptera’s low drag gives it the longest range of any production vehicle ever created – achieving up to 1,000 miles per charge and unburdening drivers from frustrating range anxiety. Its integrated solar can be configured to provide up to 45 miles of range per day with over 3 square metres and 180 efficient solar cells designed into the body structure. This makes Aptera the first vehicle capable of meeting most daily driving needs using solar power alone. Liquid-cooled electric motors propel Aptera from 0-60 in as fast as 3.5 seconds, with a top speed of 110 mph. All-wheeldrive and vectorised torque control give Aptera comfort, stability control, and the ability to handle inclement weather.

The adjustable settings built into Aptera’s user interface keep drivers updated with ways they can conserve energy and extend range in real time. Aptera has also solved key challenges allowing for rapid, high-volume, and cost-efficient vehicle production – having just four main pieces.