Environmental protection has been at the core of Chang Woen Machinery Co. Ltd’s business since it was established more than four decades ago. With its years of experience and technological expertise, the company is collaborating with manufacturers from different industries in embracing sustainability.

Chang Woen has been working with Indorama Ventures, one of the largest PET material supply enterprises, providing the latter with recycling equipment and technology for its PET requirements for F&B packaging.

FoodPacific Manufacturing Journal recently talked to Chang Woen Marketing Manager Ted Kao and Indorama Senior Manager for Recycling Division Henry Swaters on how their partnership enables both companies to achieve recycling goals and how recycling is reshaping food packaging.

From left, Indorama Senior Manager for Recycling Division Henry Swaters and Chang Woen Marketing Manager Ted Kao.

How are recycling and other sustainable practices penetrating the F&B industry?

Mr Kao: PET recycling has been going on for long, even before 2015. But in the early years, the majority of recycled materials went into the textile industry. Most PET recycled materials, for instance, were used as staple fibre in the textile industry, with big brands in the textile and sportswear segments having up to 12.6 million tonnes capacity per year.

But since 2016, trends in rPET started shifting to food packaging. As total PET bottle collection increased, the share of blow moulding also grew over the years. Demand for rPET in food-grade packaging is expected to reach 2.85 million tonnes to 3 million tonnes by 2020. In fact, big brands have set their goals for using plastic in the circular economy. For example, Evian is looking to use recycled plastic for 100% of its plastic bottles by 2025. Coca Cola hopes to collect and recycle 100% of its bottles by 2030 while PepsiCo aims to recycle 75% of its packaging wastes by 2030.

So, I see this as something that is irreversible. For food packaging, there will definitely be greater demand for recycled material, for quality recycle material.

Mr Swaters: There is increasing demand from consumers and end-users to recycle and to reuse material, especially for packaging. So, we can say that the packaging industry is also a little forced to do it by the public opinion. They will not accept nonrecycled products so you see bigger companies are more or less forced to use recycled materials.

What opportunities do you see in terms of rPET use in food packaging here in the ASEAN region, particularly in Vietnam?

Mr Kao: I see great potential. With the plastic waste import ban in China, there has been a shift in recycling opportunities and business. Other countries such as Japan, Taiwan and Hong Kong are looking to improve their in-house capability to handle waste domestically instead of exporting to China. Companies in these countries and in other areas of the world are therefore looking for high-quality machines to meet international regulations. But beyond obtaining the right machinery, they have to learn the process. They have to make sure quality is achieved; they have to improve the process of the washing line and the entire recycling system for that matter.

In Vietnam, we have observed that a growing number of recyclers are looking for good machines whilst at the same time increasing their flexibility production-wise. These are essential to ensure good quality, especially in much more value-added applications, and to achieve better margins.

For rPET used in food contact packaging applications, food safety is a top priority. How difficult is it to achieve food grade certification?

Mr Swaters: Obtaining food approval is not a difficult thing as long as you have the right machines, the right process and good manufacturing. And yes, every machine must have an approval certificate.

But that said, it’s a three-step system: There’s recycling, there’s washing and then there’s the extruder and a vacuum system. Then you must have a solid-state process behind. All these help reduce the risk that something will go wrong and boosts the chances of securing approval. In Asian countries, however, not all governments are used to or as open to using recycled products in food packaging. This means it might take some time for these governments to explore, learn and be convinced about the benefits of recycling for food applications and then subsequently change the regulations in the country.

Mr. Kao, at the Asia Manufacturing: Food, Beverages and Packaging Summit 2019 in Vietnam, you mentioned PVC and stickers as the most difficult contaminants to control in the washing line and may have harmful effects on end-users. Please expound on this.

Mr Kao: There are many impurities inside the bottles. In terms of food packaging, there are seven items in the quality and food safety parameters that we have to monitor. Two of these are the PVC and the sticker.

These two have to be managed well in the washing line because we have to [keep it down to] less than 10ppm after wash. The PVC should have less than 10ppm. The same goes for the sticker. The technology that we have—the hot washing reactor and the lever remover—are able to get rid of the contaminants and keep them down to less than 10ppm. It is quite a challenging task but with well-developed technology, years of experience and the line design itself, we are glad to be able to keep contaminant levels down and deliver to our commitment to Indorama.

A company invested in a Chang Woen washing line for HDPE bottle cleaning and recycling while a PET PCR Recycler was installed in a customer in Bangkok. What are the advantages of using these equipment for food and beverage manufacturers?

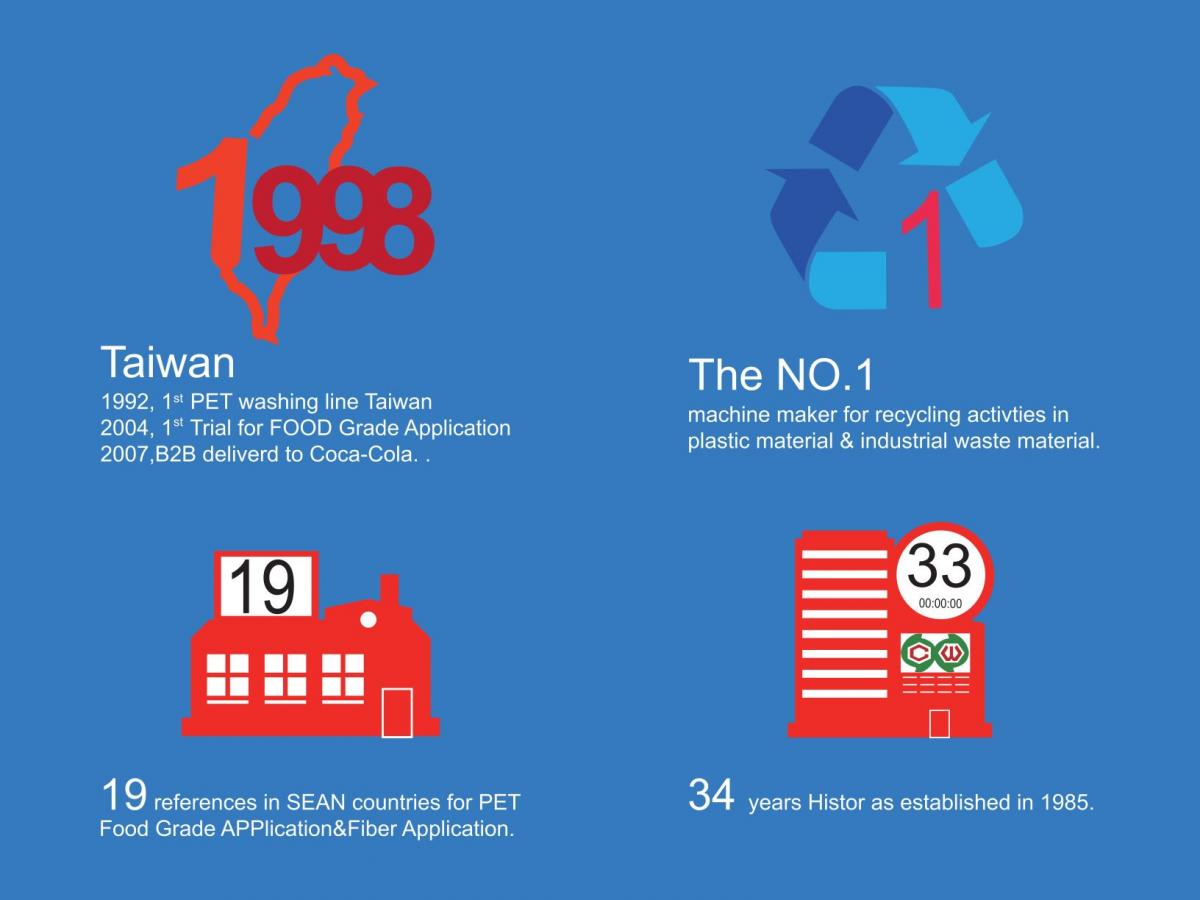

Mr Kao: We have been conducting recycling activities since 1992. The many years of experience and the know-how that we’ve built for the past decades are definitely useful, especially as we build on our reputation here in Asia, be it for HDPE recycling or PET recycling.

As for the benefits of using our equipment … You know, the contaminants inside any kind of container or food packaging will differ depending on the country. With our experience, not only can we deliver but we are also able to educate the customer. The other [thing] we bring to the table is that we are fully capable of any kind of engineering tasks. Let’s take Japan, for example. For Japan bottles we use OPS for contaminants. OPS is very different from OPP. We can come up with solutions for different contaminants with different characteristics.

Mr Swaters: I think it is also important to be mindful about the fact that when a company buys a recycling line, it cannot be just about CAPEX costs. There are also operation costs to think about. There’s energy and water consumption. There’s also waste generation. All these are very important in this recycling industry, and Chang Woen manages all these well.

As you continue to expand your machinery line for recycling, what can be expected of Chang Woen in terms of new technology and services given the current drive towards achieving a circular economy?

Mr Kao: We continue to work on new technology and innovation because, you know, packaging changes from time to time, the contaminants change from time to time and so, of course, we have to improve the technology all the time to be able to stay on top of the market. We complement this with after-sales service. We have more people. We’ve opened our own office in Japan and soon we will have our office in Vietnam. These are to be able to respond quickly to the needs of the customer so that they do not need to wait for 48 hours and can just place a call to have a local assistant guide them or address their concerns.

When is this unit in Vietnam going to be operational?

Kao: I think by 2020 we’ll have a new office in Vietnam with at least one after-sales service engineer.

How does Chang Woen respond to ASEAN customers’ demand and requirements in terms of after-sales technical services?

Mr Kao: We are looking to get more people, although of course that will depend on sales and how fast the business is growing. In Japan, for instance, we’ve established a warehouse and a factory. If business growth in Southeast Asia continues on its positive trajectory, we might even set up a hub in the region, maybe in Thailand or Vietnam.

Mr Swaters: I think in this business it is important to know that when you do not have good after-sales, you will not survive. Simply because this market is changing. For the recycler, the market is changing every month, every year as new developments emerge or are adopted, so you need the company beside you to develop new systems. Otherwise you cannot work together for a long time.

Mr Kao: One time, Indorama observed the levels are getting thinner. We anticipated problems at the washing line stage. So, they asked me to do some surveys and figure out another solution. This tells us how important after-sales service is.

For Indorama, what targets have you achieved in terms of PET recycling?

Mr Swaters: We are now able to make pellets for bottle-to-bottle recycling. There was a set of one line five years ago that’s running on capacity now. We’ve also received a big request for these pellets to use for duplication.

How does Chang Woen technology apply to your existing washing line?

Mr Swaters: It’s running pretty well. Every washing line in every country will always have small, minor problems as regards the setup. It is because the market in every country is different so you cannot copy a line used in one country for use in another. In many instances we need to customise the washing line to suit the country and company. This requires a lot of cooperation between the company and the equipment manufacturer.

What factors are driving this rising demand for use of recycled materials in more industries, especially food packaging?

Mr Kao: The top reasons for the increase in recycling activities, especially among big brands, are concerns about carbon dioxide emissions, trend for closed loop or sustainability, consumer consciousness and pursuit of what is good for the Earth. Recycling a tonne of plastic bottles saves 1.5 tonnes of carbon dioxide. Using recycled materials enables industry players to adopt sustainable practices.

Also, consumers are more conscious nowadays. Many believe products with recycled materials such as packaging have a positive impact on the environment. A growing number of consumers feel more positive about a product or manufacturer that uses recycled plastic in their packaging, with more than 80% willing to adopt a brand if the packaging is more eco-friendly.

adidas Mutator