Medical devices are subject to strict quality requirements and must conform to an array of legal regulations. In addition, there is a shortage of contract manufacturers able to fulfil these conditions. To mitigate the situation, TÜV SÜD has drawn up a range of checklists for production processes and is providing them to manufacturers. The company is also involved in numerous initiatives.

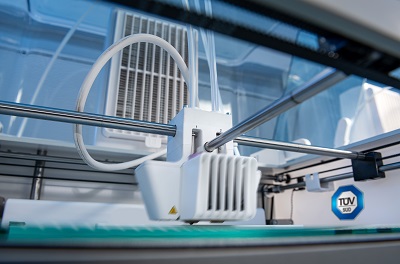

“When borders are closed to stop the spread of COVID-19, companies are forced to adjust their supply chains”, says Gregor Reischle, Head of Additive Manufacturing at TÜV SÜD. Additive manufacturing sites using 3D printers quickly reacted by concentrating resources and reducing the pressure on supply chains. 3D printing technology was one area of focus as an option for filling gaps in supply chains, most urgently concerning nasal swabs, ventilator components and personal protective equipment (PPE). At present, additive manufacturing is also boosting supplies of key products such as face visors, ventilator valves, filters, pressure sensors and X-ray tubes for applications ranging from general healthcare to high-precision personalised devices for even the most niche markets.

The benefits of additive manufacturing in a growing market

Even before the current pandemic, analysts had forecast that the market for additive manufacturing in the medical sector would grow to be worth at least US$ 20 billion. The market for AM in dentistry is set to reach US$ 9.7 billion by 2027 with impressive annual growth of 35 per cent.

Additive manufacturing offers the significant advantage of being able to close supply chain gaps by promptly ramping up capacities in series production when needed. The technology enables complex fully functional designs to be manufactured as a single piece, eliminating the need for subsequent assembly of individual parts. This can often result in higher-quality products. It also offers the capability of creating cost-effective prototypes while shortening development lead times. The pandemic has proved that both these methods can succeed – but also revealed the extensive array of device-specific provisions and regulatory requirements which apply to the products.

Medical devices must be high-quality, high-performance and safe. Proof of their compliance with numerous conformity and safety standards must be furnished before they can be placed on the market. The products may also be subject to further specific purpose-related requirements. Personal protective equipment must protect the wearer from particles, droplet aerosols and similar (Regulation (EU) No. 2016/425). Particularly rigorous conformity and safety standards apply to face masks and visors for use in hospitals and clinics. The necessary conformity assessment takes time, which is at a premium during a pandemic.

Checklists smooth the way for market access

Guidelines help manufacturers to implement regulatory requirements reliably and promptly. To assist them in this, TÜV SÜD has drawn up checklists for the main requirements addressing additive manufacturing, both general and specific, in key standards and regulations, and has been supplying these checklists free of charge to manufacturers in the coronavirus crisis. The lists are a boon for testing laboratories, healthcare specialists and the public. In addition, international standards organisations such as ASTM International and ISO provide free access to the relevant standards concerning the manufacture and testing of personal protective equipment and medical devices.

Additive manufacturing therefore is playing a useful role in battling the pandemic and is fostering willingness to innovate, which is impacting positively on the medical and healthcare sector in general. “There are many indications that fast, integrated supply chain networks with local production operations will become the new normal”, says Gregor Reischle. But the support provided by TÜV SÜD as an impartial third party is not confined to checklists. The technical service provider also develops specific tests for additive manufacturing operations which assure the quality and consistency of industrial additive series manufacturing. With the help of the tests, contract 3D printing companies can verify their conformity with the requirements set forth in the MDD and MDR.

Initiatives and projects for combating the pandemic

Governments and industry associations, multinational companies and start-ups are turning to platforms aimed at closing knowledge gaps in the industry. Siemens has provided its 3D printers to doctors, hospitals and manufacturers in need of development of medical devices or components. In addition, the company is networking its entire supply chain from the design and simulation phases through to production.

Singapore’s AM accelerator, National Additive Manufacturing Innovation Cluster (NAMIC), has set up a website containing a comprehensive list of COVID-19 resources for medical institutions, hospitals and medical device suppliers, which can then work with 3D printing hubs to design, optimise and print parts for vital healthcare equipment.

3Yourmind, an agile production software provider, created a platform for efficiently coordinating and organising supplies of essential products during the pandemic. The company has embedded TÜV SÜD’s checklist in its workflow, integrating evaluation of the manufactured products in the process.

3D printer manufacturer Ultimaker uses the COVID-19 online portal to assist healthcare centres in sourcing local production capacities. In addition, the company provides assistance with the design, pre- and post-printing and application of the printed products. Ultimaker worked with TÜV SÜD on the first checklist.

Mobility Goes Additive (MGA) is a user-oriented network that supports its members in developing medical devices and sharing technical expertise. The network is building a database of use cases, links and FAQs on face visors, masks and ventilators. TÜV SÜD is a member and supports manufacturers in implementing regulatory requirements.

In Singapore, TÜV SÜD participated in an inter-agency collaboration between the Health Science Authority, Nanyang Technological University (NTU) and NAMIC, aimed at guiding manufacturers through testing requirements to fulfil them reliably and rapidly. Checklists for face visors and nasal swabs are available free of charge from NAMIC’s COVID-19 response platform.

Last year the Centre for Additive Manufacturing at the National University of Singapore (AM.NUS) signed a Memorandum of Understanding (MoU) with TÜV SÜD which addresses research and development activities in additive manufacturing of biomedical metal implants with the aim of improving healthcare. Manufacture of these implants requires ISO 13485 certification as evidence of a comprehensive quality management system for medical devices. TÜV SÜD is contributing expertise in the form of training courses.

For more information, visit

https://www.tuvsud.com/de-de/branchen/produzierende-industrie/maschinen-geraeteausruestung/additive-fertigung/zertifizierte-unternehmen

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login