Image courtesy of Mitsubishi Electric Factory Automation

The global automation industry is at a turning point. Manufacturers are under increasing pressure to improve efficiency, meet sustainability goals, and strengthen digital resilience. Against this backdrop, two leading companies — Emerson and Mitsubishi Electric — have announced groundbreaking solutions that highlight the diverse strategies driving industrial transformation.

While Emerson prepares to showcase its intelligent Floor-to-Cloud automation ecosystem at Automatica 2025, Mitsubishi Electric has introduced its MELSEC MX Controller, an advanced motion-control platform designed for next-generation production environments. Taken together, these announcements reflect not just technological innovation, but a shared momentum toward smarter, data-driven, and more sustainable manufacturing.

Emerson: Floor-to-Cloud Automation in Action

Image courtesy of Emerson

At Automatica 2025 in Munich, Emerson will spotlight a series of live demonstrations that embody its Floor-to-Cloud vision. This approach connects machine-level components to enterprise-wide dashboards, helping companies translate operational data into actionable insights.

Highlights include:

• Plug-and-play feeding solutions for micro-part applications, adaptable across industries.

• A global dashboard that unifies performance and energy data across multiple factories.

• A high-speed pick & place system designed to reduce energy usage while increasing throughput.

• An automated pen assembly line, showcasing how Emerson’s portfolio integrates seamlessly to deliver full-system productivity.

Emerson’s narrative is about modularity, connectivity, and sustainability — enabling manufacturers to achieve carbon-neutral operations while boosting worker productivity.

Mitsubishi Electric: Pushing Motion Control to the Next Level

Mitsubishi Electric’s MELSEC MX Controller is built for speed, precision, and secure digital transformation. Capable of controlling up to 256 axes with cycle times as fast as 1.2 ms, the controller is aimed at industries where precision and scalability are paramount — including lithium-ion batteries, semiconductors, EVs, and electronics production.

Key innovations include:

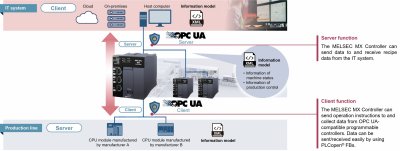

• CC-Link IE TSN Ethernet and OPC UA server integration, ensuring seamless connectivity across multi-vendor systems.

• AI-assisted, no-code programming that reduces engineering complexity and accelerates deployment.

• Cybersecurity by design, with IEC62443-4-2 compliance for robust protection of industrial systems.

• Digital twin compatibility, supporting virtual simulation and faster system commissioning.

With its MX Controller, Mitsubishi Electric positions itself as a leader in high-performance automation that is both flexible and secure.

Comparison at a Glance

|

Aspect |

Emerson (Automatica 2025 Showcase) |

Mitsubishi Electric (MELSEC MX Controller) |

Shared Connection |

|

Core Focus |

Floor-to-Cloud integration; modular, plug-and-play automation solutions |

High-speed, high-precision motion control |

Both target digital transformation in manufacturing |

|

Key Technologies |

Afag feeding & handling, Movicon SCADA, PACEdge, PACSystems |

CC-Link IE TSN, OPC UA, AI-supported tools |

Emphasis on connectivity and interoperability |

|

Target Applications |

General manufacturing, energy-efficient production, assembly automation |

EV, semiconductors, LiB batteries, LCD/food packaging |

Both enable smarter, data-driven operations across industries |

|

Sustainability |

Carbon-neutral operations; energy dashboards; efficient plug-and-play systems |

Precision to reduce waste; optimized throughput and control cycles |

Automation as a driver of sustainable production |

|

Workforce Empowerment |

Dashboards and modular tools for productivity |

AI-assisted, no-code programming for engineers |

Human + machine collaboration for efficiency |

|

Security/Resilience |

Predictive maintenance, proactive monitoring |

Cybersecurity compliance (IEC62443-4-2) |

Shared focus on reliable, secure operations |

The Connection: Different Angles on the Same Challenge

Though Emerson and Mitsubishi Electric focus on distinct aspects of automation, their announcements are deeply connected by shared industry imperatives:

• Digital Transformation (DX): Emerson emphasizes Floor-to-Cloud integration, while Mitsubishi enables real-time connectivity with CC-Link IE TSN and OPC UA. Together, these reflect the growing demand for data visibility from the factory floor to the enterprise level.

• Sustainability & Efficiency: Emerson ties its solutions directly to carbon neutrality, while Mitsubishi optimizes precision and throughput to reduce energy waste. Both approaches demonstrate how automation can become a lever for greener, more responsible production.

• Empowering the Workforce: Emerson highlights productivity gains through modular solutions and dashboards, while Mitsubishi offers AI-driven, no-code programming tools that simplify engineering workloads.

• Resilience & Security: Emerson integrates predictive maintenance and proactive monitoring, while Mitsubishi embeds certified cybersecurity standards, underscoring the need for secure, always-on operations.

The connection lies in their complementary strategies: Emerson provides broad, plug-and-play integration across the factory ecosystem, while Mitsubishi delivers deep precision at the control level. Together, these visions illustrate how the automation landscape is converging on flexible, connected, and secure smart factories.

Competing Visions, Shared Future

Ultimately, Emerson and Mitsubishi Electric are not direct competitors in every product category, but their announcements represent two sides of the same coin. Emerson’s modular Floor-to-Cloud strategy and Mitsubishi’s high-performance motion-control platform both serve the larger industry goal of transforming manufacturing into a more connected, efficient, and resilient enterprise.

Their shared direction points toward a future where automation is no longer just about machines — it’s about ecosystems: ecosystems that connect people, processes, and data into a unified vision of the smart factory.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login