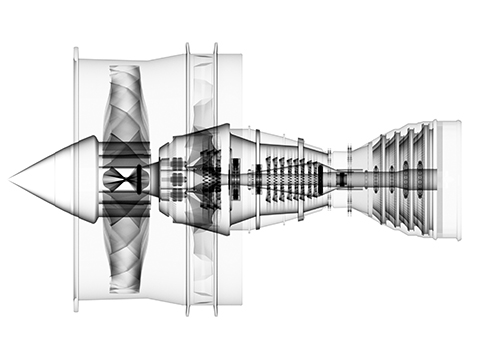

SKF continues to push the boundaries of intelligent and sustainable motion technologies with the development of ARCTIC15, an innovative temperature-resistant and corrosion-tolerant steel designed specifically for aeroengine bearings. This breakthrough material marks a major step toward enabling the next generation of high-efficiency aircraft engines, supporting the aerospace sector’s ambitious goal of achieving net zero emissions by 2050.

SKF continues to push the boundaries of intelligent and sustainable motion technologies with the development of ARCTIC15, an innovative temperature-resistant and corrosion-tolerant steel designed specifically for aeroengine bearings. This breakthrough material marks a major step toward enabling the next generation of high-efficiency aircraft engines, supporting the aerospace sector’s ambitious goal of achieving net zero emissions by 2050.

As the aviation industry advances toward more efficient architectures, new engine designs are targeting 20–25% reductions in fuel consumption and emissions. To achieve these goals, bearings must withstand higher power densities, greater loads, and extreme operational temperatures. SKF’s ARCTIC15 addresses these challenges directly, offering a new level of material performance that empowers engineers to design smaller, lighter, and more durable bearing systems.

“As aviation moves toward designing engines that aim to cut fuel consumption by up to 25%, SKF is innovating to match that ambition. Our new alloy, ARCTIC15, is a breakthrough material enabling compact bearing solutions capable of handling higher loads and speeds. This drives efficiency across the entire engine lifecycle, with repairability and sustainability at the core,” says Gregory A. Zimmerman, Director of the Aerospace Business Unit at SKF.

The journey to this innovation builds upon SKF’s deep expertise in bearing technology and materials science. The performance leap begins with replacing traditional steel rolling elements with ceramic counterparts, followed by pairing them with the advanced ARCTIC15 steel. This combination delivers higher load and temperature capacity than existing solutions, unlocking new engine architectures and improving energy efficiency.

“Through cross-functional collaboration and sustainability-driven programs aligned with global industry trends, we are helping accelerate the climate transition. As both a supplier and a customer, SKF transforms insight into practical solutions that reduce friction, cut emissions, and extend equipment life—driving industries toward a more sustainable future,” adds Hans Landin, President of Specialized Industrial Solutions at SKF.

The patented ARCTIC15 technology will be made commercially available and featured at SKF’s Patent Bay, a platform designed to accelerate sustainable innovation by offering select patents openly to companies aiming to advance environmental technologies.

The development of ARCTIC15 was sparked nearly a decade ago when SKF’s Aerospace team began engineering and testing a case-carburized stainless steel tailored for next-generation aeroengine bearings. The project drew inspiration from the EU-funded Clean Sky initiative (HEAVEN | Clean Aviation), focusing on enhancing fuel efficiency and sustainability. Extensive testing—from elemental analysis to full-scale tribological trials—validated the material’s superior endurance and resistance to severe operating conditions, including oil starvation scenarios.

SKF Aerospace factories have since produced demonstrator and full-scale bearing prototypes integrating ARCTIC15 with ceramic balls, confirming the material’s exceptional performance in real-world conditions. A ground test demonstration with a leading aeroengine OEM is scheduled for early 2026, marking a key step in achieving full Technology Readiness Level (TRL) certification.

With ARCTIC15, SKF is not only redefining bearing performance in aerospace applications but also reinforcing its commitment to innovation that drives sustainability, performance, and reliability across industries.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login