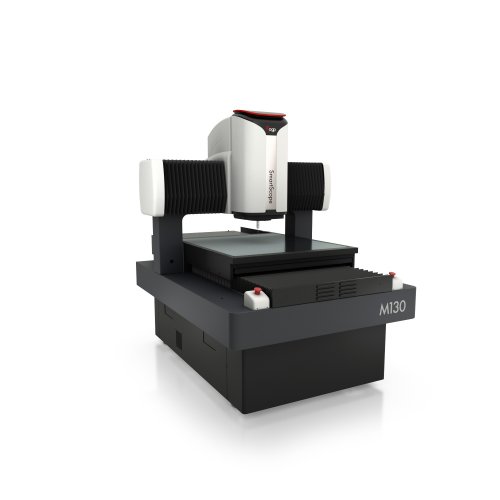

Optical Gaging Products (OGP®), a global leader in optical and multisensor metrology systems, has unveiled the SmartScope® M130, the latest evolution in its renowned SmartScope M-Series. Engineered to meet the demands of manufacturers producing large and heavy components, the new M130 delivers next-generation performance in image accuracy, optics, and throughput — setting a new benchmark in 3D multisensor measurement technology.

Optical Gaging Products (OGP®), a global leader in optical and multisensor metrology systems, has unveiled the SmartScope® M130, the latest evolution in its renowned SmartScope M-Series. Engineered to meet the demands of manufacturers producing large and heavy components, the new M130 delivers next-generation performance in image accuracy, optics, and throughput — setting a new benchmark in 3D multisensor measurement technology.

Since the introduction of the SmartScope line in 1992, OGP has been at the forefront of precision measurement, helping manufacturers worldwide achieve confidence and consistency in quality control. With the SmartScope M130, the company expands its capabilities to accommodate larger, more complex parts while maintaining the high precision and repeatability that define the SmartScope brand.

“The SmartScope M-Series has quickly become the preferred choice for manufacturers seeking unrivaled repeatability and reliability,” said Tim Fantauzzo, Vice President of North American Sales at OGP. “Larger parts often include many intricate features. The M130’s optical system is truly telecentric, eliminating distortion and enabling manufacturers to achieve accurate measurements even at low magnification — with more features captured in each field of view.”

At the heart of the SmartScope M130 lies OGP’s patented IntelliCentric-M Optical System, featuring fixed optics, a 20-megapixel camera, and the company’s proprietary VIRTUAL ZOOM™ technology. Built at OGP’s headquarters in Rochester, New York, this innovative system provides instant magnification changes across a zoom range equivalent to that of a traditional mechanical system — but without moving parts. The result is faster inspection cycles, reduced maintenance, and consistent optical stability across all magnification levels.

At the heart of the SmartScope M130 lies OGP’s patented IntelliCentric-M Optical System, featuring fixed optics, a 20-megapixel camera, and the company’s proprietary VIRTUAL ZOOM™ technology. Built at OGP’s headquarters in Rochester, New York, this innovative system provides instant magnification changes across a zoom range equivalent to that of a traditional mechanical system — but without moving parts. The result is faster inspection cycles, reduced maintenance, and consistent optical stability across all magnification levels.

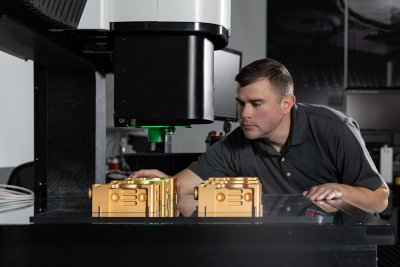

The SmartScope M130’s large measurement volume — with a standard XYZ travel of 790 x 815 x 200 mm and optional Z-axis extensions of up to 400 mm — accommodates substantial workpieces weighing up to 75 kg (165 lbs). Its redesigned base offers a lower stage height, simplifying loading and unloading of large or heavy parts and improving workflow efficiency.

“With SmartScope M130, we’ve applied the latest advancements in optics, software, and machine design to create the next generation of metrology solutions for large-scale manufacturing,” said Steve Flynn, President of OGP. “This system combines our most advanced optical innovations with the proven capabilities of ZONE3® Metrology Software, delivering unmatched throughput and accuracy across industries.”

The M130 leverages ZONE3 software’s advanced edge detection, parallel processing, and optimization features to maximize productivity and measurement precision. Combined with a full suite of advanced sensors, illumination options, and accessories, the system provides class-leading speed and versatility for complex inspection tasks — from aerospace and automotive components to precision tooling and heavy industrial parts.

With the SmartScope M130, OGP continues to push the limits of multisensor measurement technology, reaffirming its mission to provide manufacturers with intelligent, accurate, and efficient quality assurance solutions for today’s most demanding production environments.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login