In 2021, Sumitomo (SHI) Demag was enjoying its peak, with revenue and profit at historic highs. However, faced with complex market conditions in 2022, Sumitomo (SHI) Demag, long known for its solid position in the global market for injection moulding systems, came to realise that it’s time to make some adjustments.

"Sumitomo (SHI) Demag was doing fine in 2022, but we have noticed that some profound changes are taking place in the injection moulding machine market, such as the growing significance of medical market, the rapid rise of electric injection moulding machines, and enhancing trust with customers amid epidemic prevention and control. For Sumitomo (SHI) Demag, this is not just a challenge for now and for the next few years, but also an opportunity!” said Pietro Scattarreggia, CEO of Demag Plastics Machinery (Ningbo) Co., Ltd.

Rising market share of electric injection moulding machines

Mr. Scattarreggia began his analysis with the closely-watched European energy crisis as he believes that energy shortages are not limited to Europe as the energy trends in the Chinese and European markets are quite similar. “Carbon peaking and carbon neutrality goals are popular concepts around the world and a massive energy transition is underway. If we dig deeper into the current situation, we can see that the share of electric injection moulding machines and hydraulic ones on the market is about 25%:75%. However, in the last three years, we noticed that the market share of electric injection moulding machines has doubled. In going forward, we expect faster development of the electric injection moulding machines sector and estimate that by 2030, the market share of electric injection moulding machines and hydraulic machines will reach 50%:50%,” according to Mr. Scattarreggia.

Mr. Pietro Scattarreggia, CEO of Demag Plastics Machinery (Ningbo) Co., Ltd.

The reason for this change, first of all, is that most users care about their own energy bills. Energy consumption of an electric machine is lower than that of a hydraulic machine. But energy cost is not the main reason why customers should buy an electric machine as such machine type has other benefits such as higher product stability and better production efficiency, which will enable the customer to achieve higher profitability. In the end, all these advantages are converted into opportunities for the customer, making them more competitive in the market. “This is my point of view, the reason why electric machines will continue its growth in the coming years and how they will drive customers to greater success in the marketplace,” Mr. Scattarreggia stressed.

From precision parts to packaging: expanding the application of electric injection moulding machines

In the past, the main markets for electric injection moulding systems were concentrated to IT or electronic applications because of the stability and precise dimensions of their shot weight. In these applications, the size of the parts produced is usually very small, thus many cavities are formed in one shot.

The past few years also saw increasing demand for electric injection moulding machines in the medical field, as Mr. Scattarreggia stressed. This was further strengthened by the Covid-19 pandemic which required massive production of medical supplies to meet the medical emergency. Not to be forgotten is the automotive industry, which according to Mr. Scattarreggia, has taken tremendous strides in technological development. “We have seen more developments in the automotive industry, especially in the connector segment due to the surge in EV production.”

Last but not the least, the packaging industry is increasingly demanding electric injection moulding technology. “For different reasons, the energy-saving impact of electric injection moulding machine to the final product in the packaging market has risen by as much as 30%. This is a substantial saving for a packaging operation. But there is a limit because not all electric machines can process packaging products on the long run due to the technical requirements for this type of products. But going by this trend, there must be more technical solutions that can replace hydraulic systems,” explained Mr. Scattarreggia.

Born at the right moment: The Energy-Saving Packaging Machine PAC-E

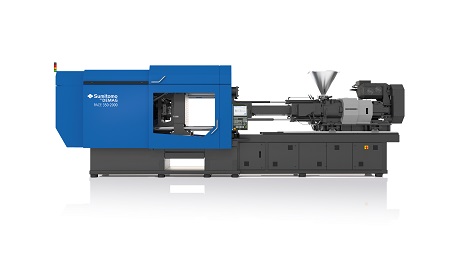

Sumitomo (SHI) Demag’s first all-electric machine lineup premiered at K 2022, exhibiting solutions for packaging, automotive, medical and other industries. The energy-saving packaging machine PAC-E with a clamping force of 350T attracted much attention at the show.

PAC-E is a new all-electric, high-speed injection moulding machine engineered specifically for manufacturers of beverage closures and thin-walled packaging applications. Combining all of Sumitomo (SHI) Demag’s know-how, the machine features toggle levers, plates, tie bars and plasticizing elements, including the screws and cylinders that were developed in Germany; while the electric drives and the newly developed injection unit with excellent injection performance were derived from the Japanese parent company.

The energy-saving packaging machine PAC-E with a clamping force of 350T debuted at K 2022.

“Sumitomo (SHI) Demag is currently doing very well in the packaging market. Normally we focus on applications below 5 seconds and sometimes we run applications with a cycle time of 3 or 2 seconds. For that application range, it's quite tough to run these applications with standard electric machines. This is why we developed an injection moulding system with a specific drive technology that can easily cover the demands within this range. And as a result of many years of experience in the packaging industry and in electric machine technology, we designed the PAC-E machine and we took advantage of the opportunity at K 2022 to introduce this really interesting product to our customers,” according to Mr. Scattarreggia.

The market launch of PAC-E is set in mid-2023 starting with the 350T, with plans to roll out remaining clamp force sizes in succession. Mr. Scattarreggia expressed that they already know the excellent performance of the PAC-E during the design and testing phase. “The story can only be written by the machine itself and by the experience of our customers. So I`m convinced this machine will have a great future ahead, with story to tell in terms of performance and benefits to our customers,” Mr. Scattarreggia explains.

Medium- and large-sized hydraulic presses retain market advantages

Although the development of electric injection moulding machines is in full swing, medium- and large-sized hydraulic presses still have their unique advantages. In the packaging field, for instance, when running applications with a certain cycle time, the hybrid machine is still the technology of choice. Sumitomo (SHI) Demag has an excellent product – the Systec SP which has become popular in China. “We still offer hydraulic machines in bigger range, for applications from 300T up to 1,500T. This kind of machines are focused on the automotive and the consumer goods markets,” said Mr. Scattarreggia.

The Sumitomo (SHI) Demag team at K 2022.

And for this tonnage, the electric machine will play a less significant role. “I expect the tonnage below 250T will be nearly completely converted to electric driven machines. By 2030, the share of electric machines in the range up to 250T will be about 80%. But this means also that we still need to continue to offer to our customers our hydraulic and also hybrid driven injection moulding machines for the tonnage above this range.”

Looking for the next business opportunity

With anticipated robust growth in the China market in the future, Sumitomo (SHI) Demag is currently increasing capacity at its Ningbo plant as one of the strategies to meet growing demand in the Chinese market. It has also been walking with "multiple legs." Looking back over the past three years, packaging, medical and automotive markets were the company’s best-performing application markets, keeping the balance in terms of revenue contribution.

A few years ago, Sumitomo (SHI) Demag made considerable investment in healthcare. The company has designed and launched suitable injection moulding machine models for medical applications. Over the past three years, Sumitomo (SHI) Demag has seen a surge in medical needs, which to a large extent compensated for the slowdown of the automotive business. "For us now, medical and packaging businesses remain at a relatively stable level. We will focus more on the electric vehicle market, especially in China, because the demand in this area is growing rapidly," Mr. Scattarreggia pointed out.

He predicts that the injection moulding market will be more stable in the next few years. “Everyone has experienced huge logistics fluctuations over the past three years, along with severe shortages in the supply chain. It seems to me that we now have an opportunity to go back to a more normal and stable level. That’s why I’m very optimistic about the future.”

In Mr. Scattarreggia’s eyes, customers and suppliers are the key elements in Sumitomo (SHI) Demag’s success. “We currently use very common online tools to communicate with customers and suppliers. We also visit some clients if possible. Then, we have frequent phone calls with our customers as part of establishing good relationship with them. We also exchange ideas and communicate with them regarding our future plans and expectations.”

Even with the slowdown in the economy, many customers are still optimistic. More orders are coming in, a case in point is the automotive industry with the focus on increase production of electric vehicle. Next year, Demag Plastics Machinery (Ningbo) Co., Ltd will celebrate its 25th anniversary – reflecting how it has quietly established its strength and gradually developed into one of the most successful models of localization in China's injection moulding machine industry.