The convenience of plastic is hard to give up, and for the past half-century, it has been closely intertwined with human life. However, over time, plastic has been widely criticized as an environmental hazard. Take plastic bags as an example. Although they are convenient, they cause significant harm to the environment and have been labeled as ecological killers. As a result, food manufacturers have started to change their packaging methods, and "material unification" has become the focus of research and development for various manufacturers.

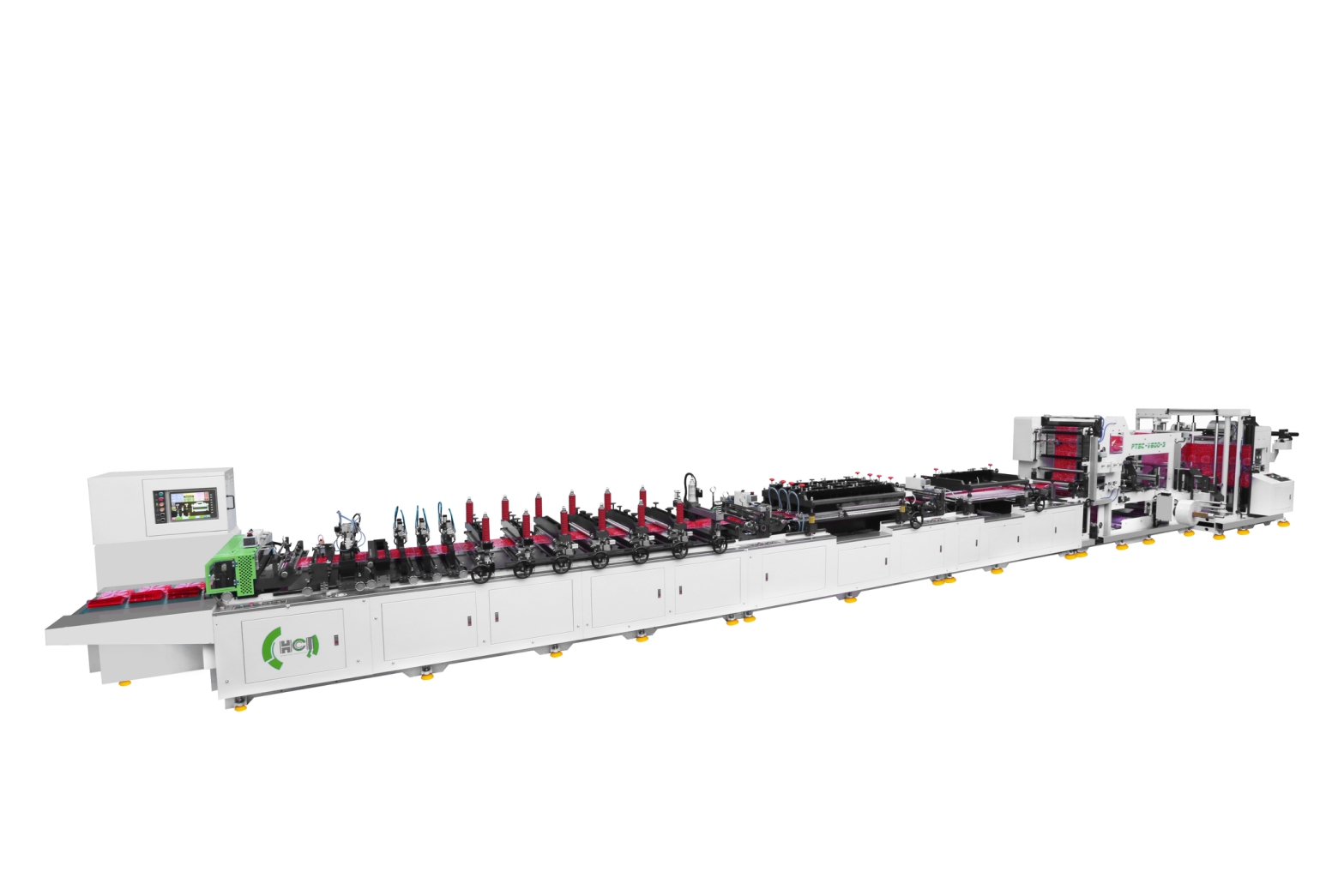

FTSC-V Three-Side Seal Bag / Standing Bag / Zipper Bag / Four-Side Seal Bag Making Machine. Courtesy of HCI

HCI Converting Equipment Co., Ltd. has pointed out that flexible packaging products are typically made from composite film packaging materials consisting of various materials. These materials pose a challenge when separating and recycling them for reuse.

In response to the demand for a circular economy and easy recycling, packaging material manufacturers have developed "mono-material composite films (e.g. BOPET)" to replace the current heterogeneous composite film (e.g. PET+PE) as the raw material for food packaging bags. However, the company stated that the melting point temperatures of the sealing and outer layers of the mono-material composite film are relatively close to each other. As a result, when using traditional bag-making machines to seal the film under high-temperature conditions, it often results in the melting through of the inner and outer layers of the material or serious wrinkles at the sealing point.

The company collaborated with the Plastics Industry Development Center (PIDC) to improve the heat-sealing seat structure and control system of the bag-making machine. This adjustment allowed for more precise temperature control and pressure adjustment, making it suitable for the new generation of materials used in the bag-making industry. As a result, the company has successfully produced single-material PET sustainable packaging plastic bags.

As a manufacturer of flexible packaging processing equipment, HCI is committed to developing green technologies, utilizing recycled or recyclable materials whenever feasible, and producing more durable, long-lasting equipment. These efforts will not only help reduce carbon emissions but also assist customers in optimizing their processing operations, enhancing efficiency, and minimizing energy consumption and waste generation. "By working together, we aim to protect the Earth's environment in a sustainable manner," the company stated.

Please scan the QR code above to watch HCI’s latest solution video.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login