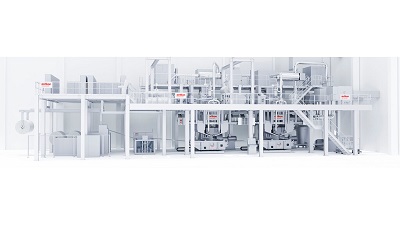

Oerlikon Nonwoven has commissioned a further high-performance meltblown system with ecuTEC+ electro-charging unit at NOWOtex GmbH & Co. KG in Eichenzell, Germany. The Hesse-based company specialises in needled nonwovens and – with the new system – now also has meltblown nonwovens manufacturing capacities, allowing NOWOtex to expand its product portfolio. As of now, the company is producing polypropylene filter nonwovens, which are particularly suitable for protective masks. The coronavirus pandemic has not only increased demand for protective masks, the domestic manufacture of these products is now also be promoted and supported by the German Government.

Using the new meltblown system, NOWOtex will in future be manufacturing first-class filter nonwovens that can be used to produce up to 600 million operating room filter masks or 300 million highly-effective FFP2 masks per year. The system has been optimally equipped with the ecuTEC+ electrocharging unit for the production of mask nonwovens.

The system is also ideal for manufacturing other high-end filtration nonwovens for industrial applications. The Oerlikon Nonwoven system offers maximum flexibility, NOWOtex to not just manufacture nonwovens for mask but also launch new NOWOmelt product range, providing its clients with an even broader range of innovative nonwovens

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login