Rockwell Automation, Inc., the world’s largest company dedicated to industrial automation and digital transformation, released the new Allen-Bradley FLEX 5000 analog safety I/O modules to help process operators meet fail-safe requirements and minimize related downtime risks in a wide range of process applications.

Rockwell Automation, Inc., the world’s largest company dedicated to industrial automation and digital transformation, released the new Allen-Bradley FLEX 5000 analog safety I/O modules to help process operators meet fail-safe requirements and minimize related downtime risks in a wide range of process applications.

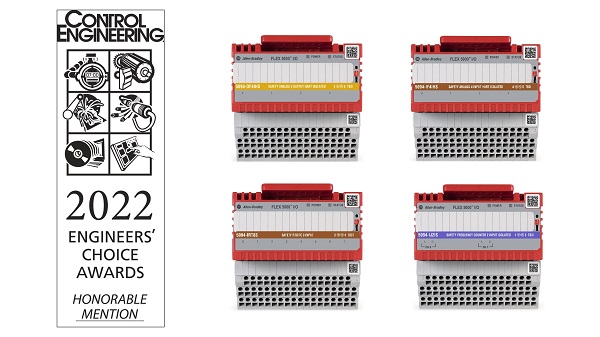

The analog safety I/O modules from Rockwell Automation offer integrated safety with systematic capability up to SC 3. The modules are TÜV certified up to SIL 3, PLe, Cat. 4. They also can be mounted in the same I/O bank with standard FLEX 5000 I/O modules to reduce system costs and complexity.

The FLEX 5000 analog safety I/O modules are ideal for process applications where speed or frequency measurement, temperature, pressure, or flow sensor monitoring are required for functional safety protection. Potential applications include emergency shutdown, burner management, turbine control, compressor control, oil and gas auxiliary boilers, high-pressure protection, lighting, and ventilation management.

With these new modules, the FLEX 5000 product family now includes a complete portfolio of discrete and analog fail-safe I/O modules for a wide range of applications. Users can simply choose the I/O that meets their operational needs.

FLEX 5000 I/O can also reduce downtime by providing easier access to additional process diagnostics via highly integrated HART in the Studio 5000 Logix Designer application. They can reduce overall footprint by allowing the direct termination of field signals. And they can save engineering time via tight integration with instruction sets in PlantPAx 5.0 and above systems.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login