Oerlikon Barmag, a leading manufacturer of high-tech components for the production of compound materials, is presenting its precision metering pumps at this year's PU TECH India trade fair. The event, which takes place in New Delhi from April 12 to 14, is the international polyurethane industry's premier event. Oerlikon Barmag's pumps are designed to deliver tailored solutions for the most demanding technical tasks in polyurethane applications and the paints and lacquers industry.

Processing polyurethane is a complex task that requires accurately defined, even metering of various liquid materials in numerous chemical processes. Oerlikon Barmag's metering pumps are responsible for this precise metering, ensuring high-quality end products and efficient production processes. The company's GA range of pumps is designed for conveying media with higher viscosities of up to 1,500 Pas and temperatures of up to a maximum of 225°C. They are characterized by short flow channels and highly wear-resistant tool steels, providing tailor-made solutions for applications requiring accurately defined, even metering.

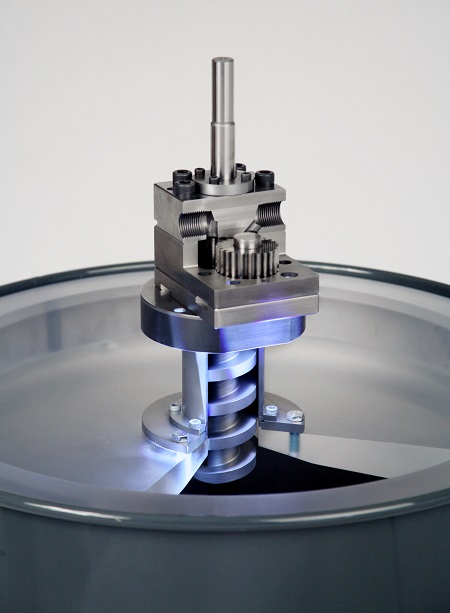

Specialist for conveying and metering high-viscosity materials: the Oerlikon Barmag drum pump.

In addition to the GA range, Oerlikon Barmag has developed a new eccentric screw pump range that is robust and durable. It is ideal for conveying highly-filled, high-viscosity, and abrasive media. The multi-stage seal system considerably increases the pump's lifespan, with the upstream shaft sealing ring protecting the slide ring seal against excessively-fast wear caused by challenging media. The optimum alignment of the drive shaft also prevents any metal debris caused by friction, ensuring considerably greater durability. This pump range is tailor-made for conveying and metering high-viscosity materials from drums, removing the need for scoop-piston pumps used to date.

Oerlikon Barmag also offers magnetically-coupled GM metering pumps for high-precision metering of toxic materials in hermetically-sealed environments. The company's shaft seals with stuffing boxes, shaft sealing rings, or slide ring seals are possible for standard applications. The GM series with the round plate package has been expanded to include an option for pressure build-up capacity for use in high-pressure technology with small throughputs and low viscosities. It guarantees the build-up of the required high operating pressures, permitting higher volumetric degrees of efficiency or a greater useable speed range. For manufacturers of polyurethane molded parts, foam slab stock, refrigeration unit insulations, and sandwich panels, this means constant process stability at lower investment costs.

Oerlikon Barmag’s eccentric screw pump is tailor-made for conveying high-viscosity, abrasive and highly-filled media.

Oerlikon Barmag's precision metering pumps offer tailor-made solutions for the most demanding technical tasks in polyurethane applications and the paints and lacquers industry. The company's products are designed to deliver high-quality end products and efficient production processes, providing customers greater productivity, increased lifespan, and tailored solutions for even the most complex processes. The company's commitment to innovation and its customers' needs ensures that it will remain at the forefront of the industry, offering cutting-edge solutions that meet the demands of the modern world.

For further information, visit www.oerlikon.com/polymer-processing.