Path to a Greener Tomorrow──

Chyi Yang's CFV Solutions of Precision and Sustainability

International Plastics News for Asia | Chi-Chuan Cheng

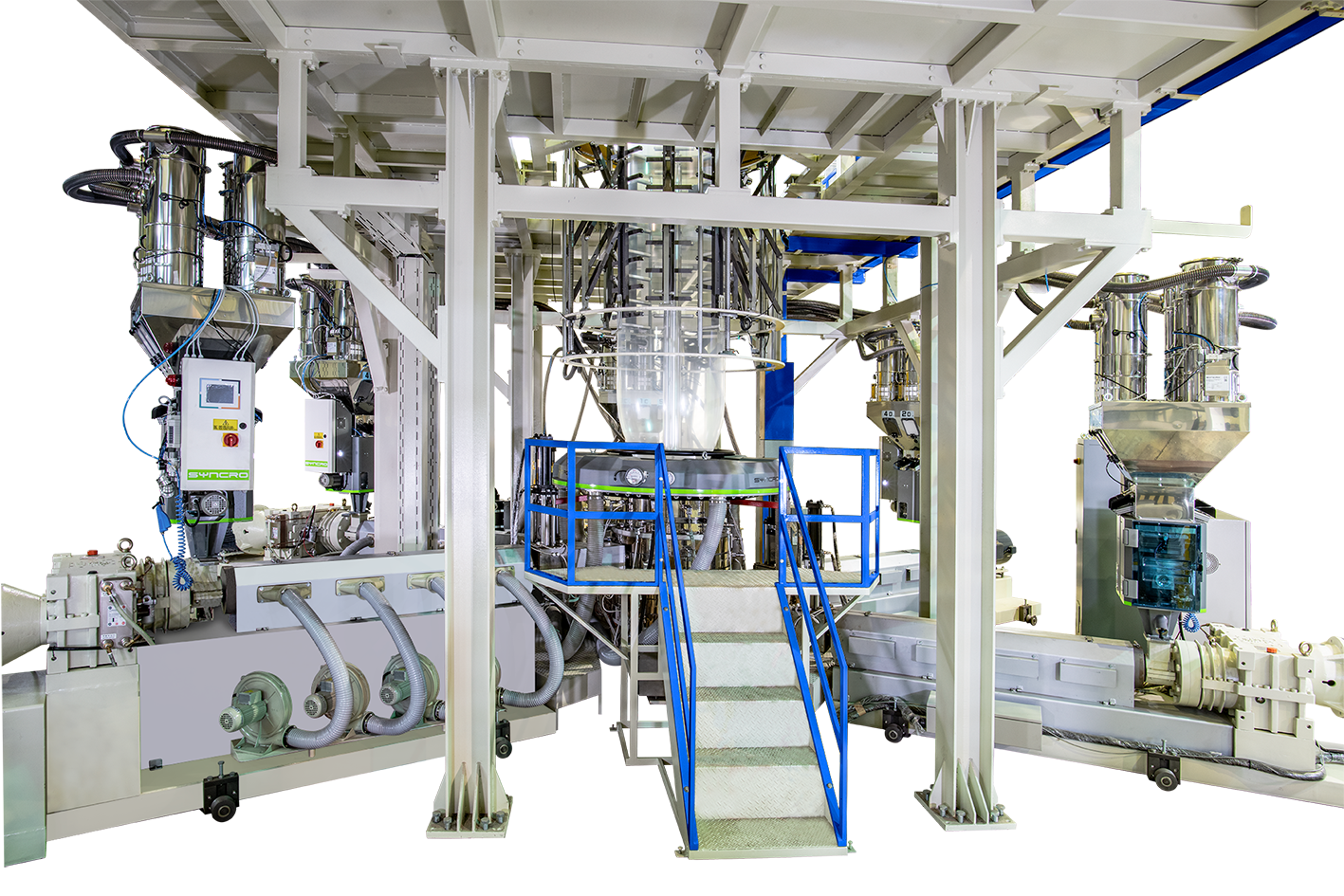

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

Are you ready for the CFV standards?

With environmental standards increasing annually, the manufacturing industry is facing pressure to decrease carbon emissions and enhance energy efficiency to meet the Carbon Footprint Verification (CFV) requirements of the market. CFV refers to the use of scientific methods to calculate the carbon emissions of an enterprise or organization's activities in accordance with international standards, such as ISO 14064 and the Greenhouse Gas Protocol. This includes all aspects of a company's production and supply chain transportation. As a result, the use of scientific data by multilayer blown film manufacturers to understand their points of high carbon emissions and plan their strategies for carbon reduction has become the latest trend in the market.

One of the critical steps in the CFV process is "Direct Greenhouse Gas Emissions (Scope 1)". This step is especially important for the blown film industry, as it necessitates both technological innovation and environmentally friendly production methods. With this in mind, Chyi Yang assists its clients in leveraging smart manufacturing technologies and digital system software tools to achieve carbon reduction based on lean management principles. This is done by reducing unnecessary waste, improving line efficiency, optimizing energy efficiency, and increasing the use of recycled materials; such a layout not only reduces carbon emissions but also achieves digital transformation. Therefore, the introduction of Chyi Yang's forward-thinking design of a 5-layer / 7-layer blown film machine provides a ray of hope for the bag-making and film-making industry. This industry is known for its complexity in terms of process and recycling, but with this innovative machine, it can now strive to achieve the goal of reducing carbon inventories.

Must-know: Eco-efficiency multilayer blown film production

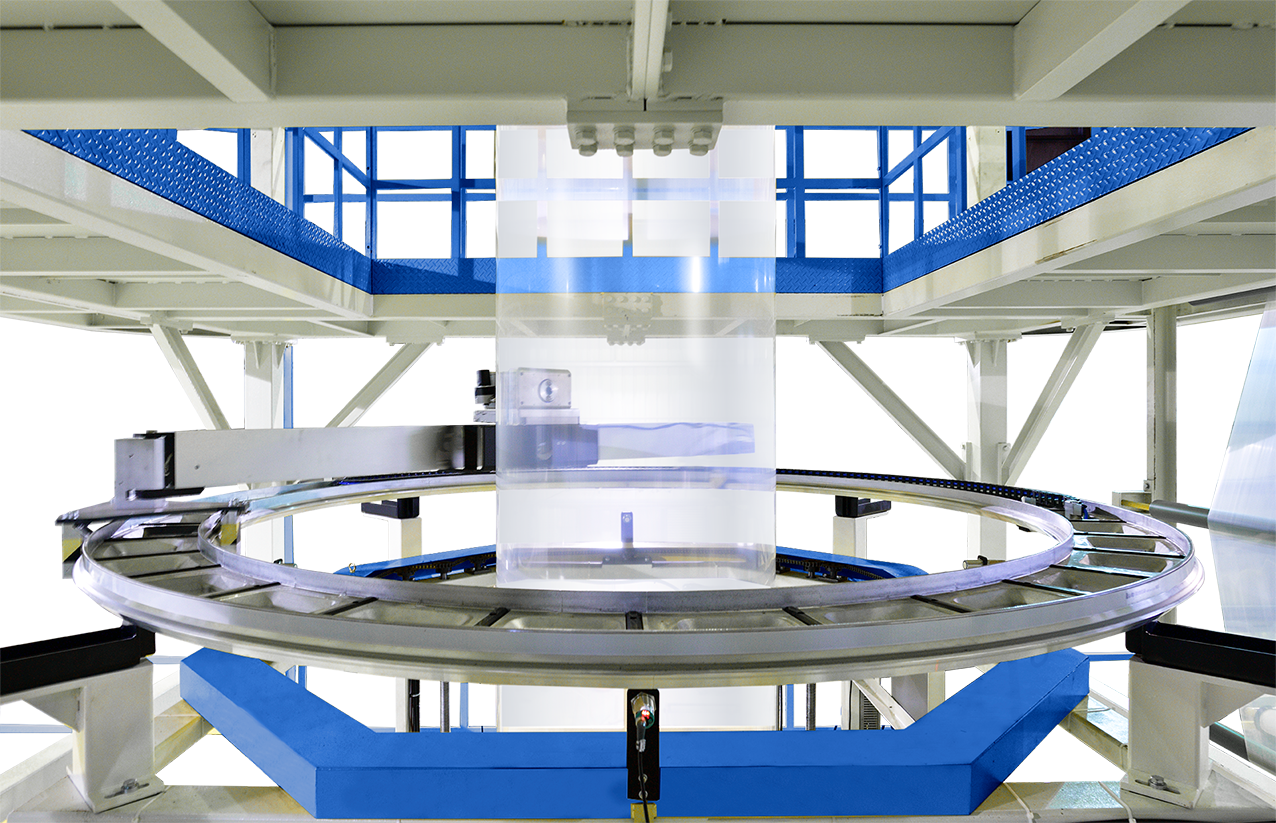

Chyi Yang's 5-layer / 7-layer blown film machine has revolutionized the recycling of trimmed waste. Instead of the usual problem of manufacturers struggling to accurately measure the weight of recycled film debris, which makes it challenging to estimate the percentage of waste that can be reused, Chyi Yang's multi-layer blown film machine model can effectively address this issue. The machine is capable of heating the waste, extruding it through a small screw, cutting it, air cooling it, and granulating it, among other functions. It automatically sucks the waste back into the weighing system for recycling. At the same time, manufacturers can use its precise formula calculation function to establish more accurate formula addition ratios during the 24-hour non-stop operation of the machine. The combination of these two features can effectively reduce waste and enhance the efficiency of the circular economy. The utilization of this add-on for the multilayer blown film machine not only reduces waste in the production process but also yields excellent results in the CFV's step 2 (carbon reduction).

In addition, Chyi Yang's high-speed multilayer blown film machine can also assist manufacturers with big data analysis, adjust production parameters according to process conditions, automatically control the ratio and addition of various raw materials, automatically refill materials after pre-setting, check the adequacy of raw materials, and provide immediate reminders and replenishment, which can greatly reduce downtime and frequency, improve yield and productivity, and shorten lead time, and at the same time, reduce the impact of the manual operation on the formula, which can, in turn, improve the yield rate of the multilayer blown film machine production line. By leveraging digital transformation to optimize the production process, Chyi Yang's multilayer blown film machines not only significantly decreas the overall power consumption of the production line, but also cut labor costs through fully automated production line, which in turn help customers to achieve the goal of green transformation.

Manufacturing challenges in a net-zero era

The global issue of greenhouse gas emissions is becoming increasingly serious. To address the threat of extreme climate change, governments are proposing net-zero emission targets for the period between 2025 and 2030. In light of the CFV trend, the manufacturing industry must quickly adjust its strategies to meet the challenge of adhering to international environmental trends and increasingly strict regulations. Particularly in Europe and the US, there is an increasing demand for environmentally friendly products. This has created an urgent need to reduce carbon emissions in the manufacturing of multilayer blown film products.

Chyi Yang's new 5-layer / 7-layer blown film machine is an ideal solution for reducing carbon emissions and energy consumption. With decades of experience in technology innovation and customized design capabilities, Chyi Yang has helped many customers meet environmental protection standards. The machine not only ensures high production efficiency but also contributes to sustainable development and green transformation.

Benefiting from the high quality and efficiency of Chyi Yang's multi-layer blown film machines, many leading plastic manufacturers in Southeast Asian markets, such as Indonesia and Vietnam, have chosen to collaborate with Chyi Yang to establish a complete production line of multi-layer blown film machines. For decades, Chyi Yang’s committed to assisting more manufacturers in accelerating the trend of net-zero transformation and paving the way for the sustainable development of enterprises. This is not only a responsibility and a commitment to future generations, but also an initial opportunity that manufacturers must seize in order to face future market competition.

CHYI YANG INDUSTRIAL CO., LTD

E-mail: cymw@cymw.com.tw

Website: https://www.chyiyang.com/about-chyiyang

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login