By FRANK MÖLLERING

Head, R&D Department, Nutriswiss AG, Switzerland

NUMEROUS studies have shown in recent years how important omega-3 fatty acids are for our minds and bodies. The consequence of this increased awareness is a booming market. One particularly important area of application is infant formulas. The fatty acid DHA (docosahexaenoic acid) is considered to be essential for the first years of development, so much so, in fact, that it’s a mandatory component in some regions such as the EU1. In other countries such as Malaysia and China, DHA and arachidonic acid (ARA) are optional but desirable additives because of the health benefits they offer for infants2,3. In these special applications, if not in every food, quality plays a critical role. Omega-3 oils oxidise extremely quickly and, like any crude oil of plant or animal origin, can become contaminated during cultivation and/or transport. These valuable fatty acids are derived from vegetable, algae or fish oils, and it’s especially the latter that pose the greatest challenge in terms of neutralising their inherent fishy odour and taste. A company that specialises in these demanding oils is the Swiss refinery, Nutriswiss. Using experience and state-of-the-art technology, they’ve found a balance by using processes that are both gentle and as thorough as possible.

Purity you can taste

Most food operators are extremely well informed about the hurdles that have to be overcome when using oils containing polyunsaturated fatty acids such as omega-3 and omega-6. When they come into contact with oxygen in the ambient air, an oxidation reaction takes place that induces decomposition. The consequences of this conversion manifest themselves as off notes and an unappealing taste, especially with fish oils. The ketones and aldehydes that are formed as the oil breaks down produce a dark colour and, sometimes, a strong “fishy” smell and taste. But it’s not just sensory properties that make a good omega-3 oil, purity is also crucial.

Thanks to increasingly precise analytical methods and the results of numerous scientific studies, the detection limits for contaminants are constantly lowering. Subsequently, the levels of legally permitted amounts of residues have become much more stringent around the world.

When it comes to products for babies or other sensitive groups, expert knowledge is key; ensuring that any impurities present in the raw material are minimised and preventing both the formation of process contaminants and the loss of valuable fatty acids is essential.

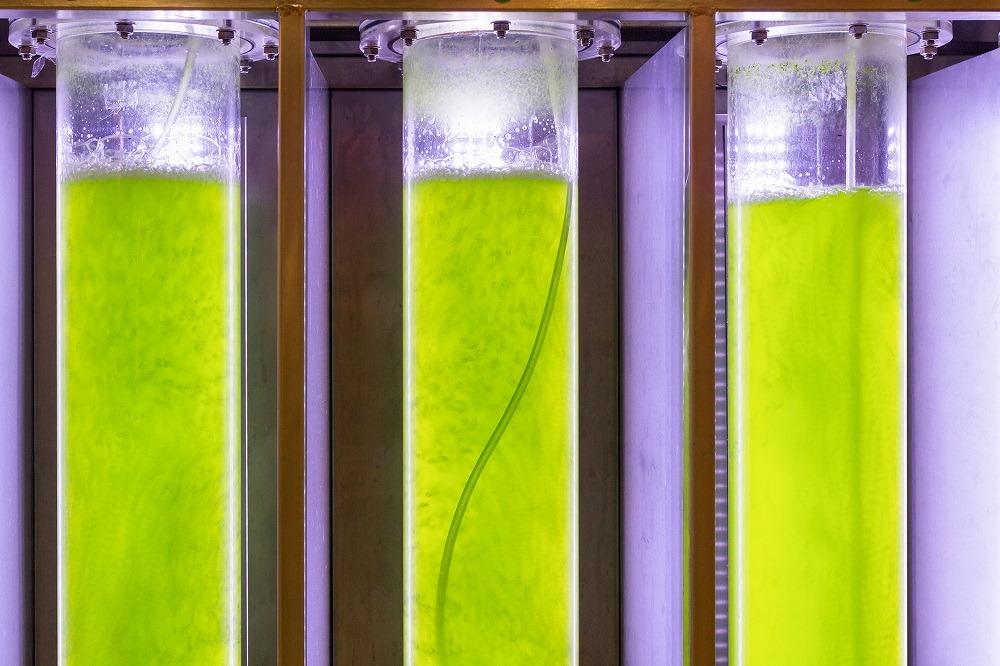

Oil from microalgae is a high-quality source of omega-3 but requires particularly careful handling. (Photo © 123rf/Akhararat Wathanasing)

Susceptible to contaminants

For apolar lipids, which are vulnerable to fat-soluble contaminants, there are inherent risks throughout the entire process chain. During cultivation, transport and certain pre-processing steps, mineral oil hydrocarbons (MOSH/MOAH) and solvent residues may be formed or accumulate.

Of all the common omega-3 sources, microalgae cultured by fermentation under controlled conditions in tanks have the lowest contamination levels and a high fatty acid content (up to 50% of the cell dry weight). Plants such as rapeseed or linseed can incorporate environmental contaminants, mycotoxins and certain plant toxins, as well as high-molecular weight pesticides, fungicides or herbicides that were used during cultivation.

Fish oils can also be polluted, for example, with polychlorinated biphenyls (PCBs) or dichlorodiphenyltrichloroethane (DDT), which is still present in the environment despite a global ban. Even more critical, however, is their tendency to rapidly undergo oxidation, which can only be stopped or reversed with sophisticated refining techniques. All omega-3 oils require customised treatments and a higher degree of care than ordinary oils to preserve their essential fatty acids, micronutrients and vitamins.

Nutriswiss specialises in refining speciality oils and those that have to be particularly pure for special applications. (Photo © Nutriswiss)

Method of choice

Classic refining processes take place at temperatures between 180 and 250 °C. Heat accelerates the degradation of the polyunsaturated fatty acids and leads to the formation of contaminants, including glycidol and chlorine-fatty acid esters such as 3-MCPD. To prevent this, Nutriswiss has established various innovative processes. They expose the raw materials to minimal thermal stress while maximising yields and minimising impurity levels.

This approach can even be used to treat oils that are heavily contaminated or when an extremely pure end product is required. Free fatty acids, plasticisers and pesticides are removed to an extent that cannot be achieved with conventional technology. Similarly, MOSH/MOAH levels can also be significantly reduced. Companies that want to minimise contamination risks from the outset can rely on Nutriswiss’ own, cost-effective raw material sourcing service.

Challenging processes

Nutriswiss purifies, neutralises, bleaches, filters, deodorises, modifies and mixes crude oils from a wide range of sources. The company enjoys an excellent reputation worldwide, especially as a supplier of high-purity oils and niche products. To cite an example, one of the most commonly used indicators of the degree of oxidation is the anisidine value. In the case of fish oils, the removal of secondary oxidation products makes it possible to reduce the anisidine value to less than 10 and, in some cases, less than 5, which corresponds to premium quality.

Added to this is the sensory neutrality and the light-yellow colour, which is similar to that of rapeseed oil. To ensure that the key product data and sensory profile meet the requirements for pharmaceutical or special nutrition products, the refining steps are carefully planned and monitored. For instance, the composition of a baby food formulation, including the optimum ratio of omega-3 and omega-6, can be developed according to specific customer requirements.

And, although fish oils still rank highly as a source of omega-3s, algae’s position in this market is set to become more prominent in the future. Thanks to years of experience in this industry, Nutriswiss is ideally equipped to meet the world’s increasing demands for refined fish and algae oils.

References

1 Delegated Regulation (EU) 2016/127 of the Commission of 25 September 2015.

2 P.U.(A) 437/85, FOOD REGULATIONS 1985, incorporating the latest amendment: P.U.(A) 208/2020, p 155: http://fsq.moh.gov.my/v6/xs/page.php?id=72.

3 USDA Foreign Agricultural Service, “China: China Notifies Infant Formula Standard,” 25 June 2021: https://www.fas.usda.gov/data/china-china-notifies-infant-formula-standard.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login