Global manufacturing has been struggling in recent years to address the labour shortage. The wave of automation has arrived quickly due to the significant impact of global pandemic, wars, and other "black swan" effects - and the market's industrial upgrade is about to occur. Right now, it appears that there is a major global supplier of film-blowing technology who has been quietly offering automated equipment solutions for years, aiding in the establishment of "unmanned factories," and strongly supporting these film manufacturers to successfully pass the "post-pandemic era." Chyi Yang Industrial Co., Ltd. is the super provider of this key blown film line solution.

"Lights-out manufacturing" is the key technology behind winning 80% market share

When a team of maintenance technicians entered a giant cling film factory in Shandong, China more than 10 years ago, they reached out and turned on the lights and all they could hear was the low-frequency rumble of the running machines in the blown film line. Not a single person was seen operating the machines; the factory signifies the beauty of post-modernism. It turns out that the factory had already introduced automated film-blowing technology and automated production 24/7 by means of lights-out manufacturing.

When the semi-finished products of the blown film line are moved to the rewinding process, the paper rolls could be automatically loaded and unloaded. With the large storage capacity of the paper barrel, the machine can quickly rewind the rolls and then automatically unloading them; 10 rolls of 30 metres long can be rolled in one minute, which is as precise and efficient as an automatic machine gun. The key solution behind this advanced automated production line is the work of Chyi Yang's whole plant planning and design.

The film manufacturer giant continued to grow with Chyi Yang's excellent and stable production technology of blown film line and equipment, successfully winning 80% of the market share in the region, and this success also attracted another brand to enter the market, making it an even split between the two major brands to date. Less well-known is the fact that this second startup's success also depended on asking Chyi Yang's team for help with factory planning and automated production line optimisation so they could continue to produce goods with excellent quality and efficiency.

For decades, Chyi Yang has helped clients easily transform to automation

Today, Chyi Yang's customisation technology has not only caught up with the world's largest manufacturers but has also successfully become a high standard in the Asian blown film market. The company has customers in Asia, Europe, the Americas, and Africa; Chyi Yang has entered the high-end market in Japan and the emerging East Asia, such as Vietnam and Indonesia, where its blown film lines have been used exclusively to produce film products.

Young manufacturers in Southeast Asia prefer to purchase their multi-purpose entry-level film-blowing machines that can semi-automatically rewind, cut, unload, and produce several types of film products to reduce the difficulty of entering the market.

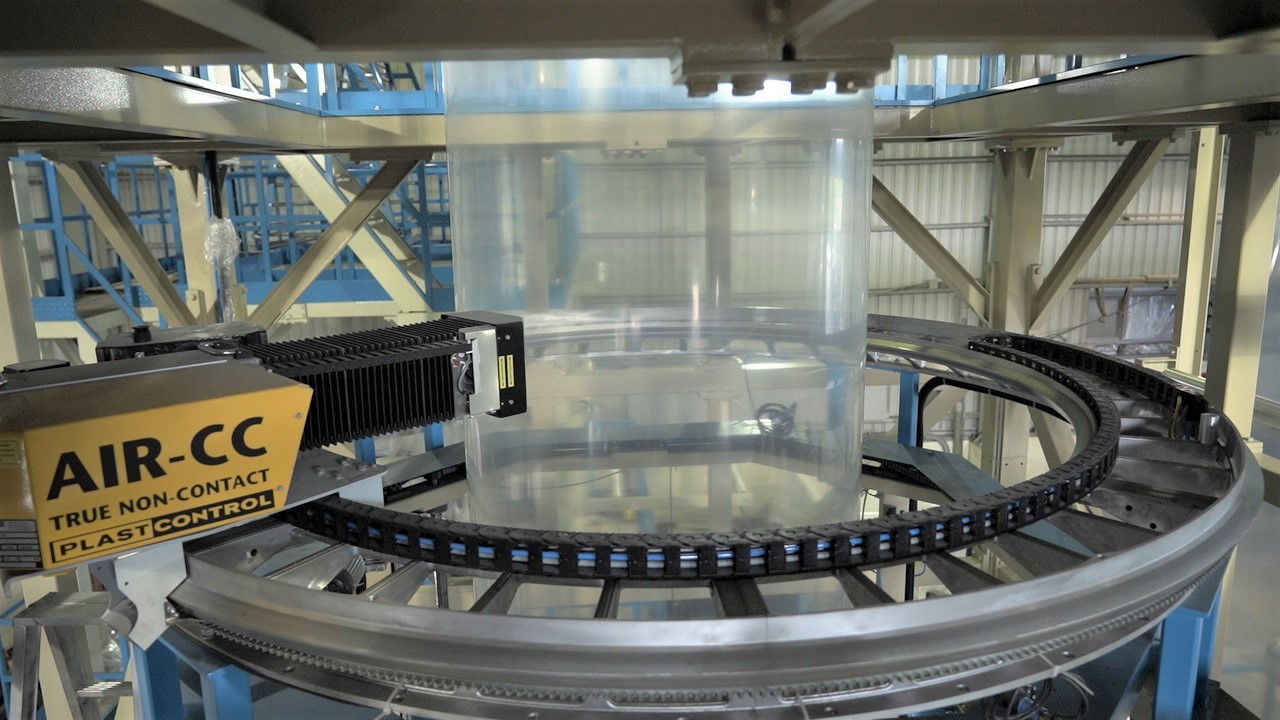

For high-end models, Chyi Yang is also taking advantage of the smart manufacturing trend and will launch the latest three- and five-layer automatic film-blowing machine in 2022, which are installed with fully automated equipment and a control system to auto-adjust and track the width and thickness of the film produced, simplifying the process that relies on human adjustment and significantly improving quality stability and consistency. Both high-end and entry-level models are developed to meet today’s blown film line users' needs, and Chyi Yang has grown and expanded with its customers along the way.

While Vietnam and Indonesia are competing to replace China as the world's factories, the highly sought-after Chyi Yang film-blowing equipment can provide stable production for 20 to 30 years, making it easier for international manufacturers to enter the Southeast Asian market. As an expert in blown film lines, Chyi Yang uses self-designed and manufactured core components such as die heads, main engines, gearboxes, and air rings; therefore, the Japanese consultant attested to the exceptional quality of the details, and the manufacturers were advised to make use of all factory machinery.

With a heart for customers, Chyi Yang has maintained its excellent reputation since its establishment in 1965, and has not only received CE certification from the European Union as early as 2001 but has now introduced automatic blown film production technology to the industry. Throughout the 6 decades, Chyi Yang has continued to strive to provide customers with more services and value beyond the surface of the quotation list.

For more information, visit: www.chyiyang.com