By MIFLORA M. GATCHALIAN, PhD., CEO, QUALITY PARTNERS CO. LTD (QPCL)

THE MAJOR goal of any worthy business organisation is to gain and sustain profitability. Towards this end, many approaches had been promoted but only few have consistently attained success. Through the years, at least since 1996, Quality Partners Company Ltd (QPCL) implemented various approaches to assist the industries particularly the small and medium enterprises (SMEs). These experiences revealed that a culture-based approach to total quality management (TQM), could help sustain the achievement of quality, productivity and profitability (QPP). The approach followed the acronym SUGOD (Survey-Unite-Grow-Operationalise-Develop), a Filipino word for “move-on together fast”. This paper will briefly explain how quality, productivity, profitability (QPP) can be sustained through the SUGOD for TQM approach.

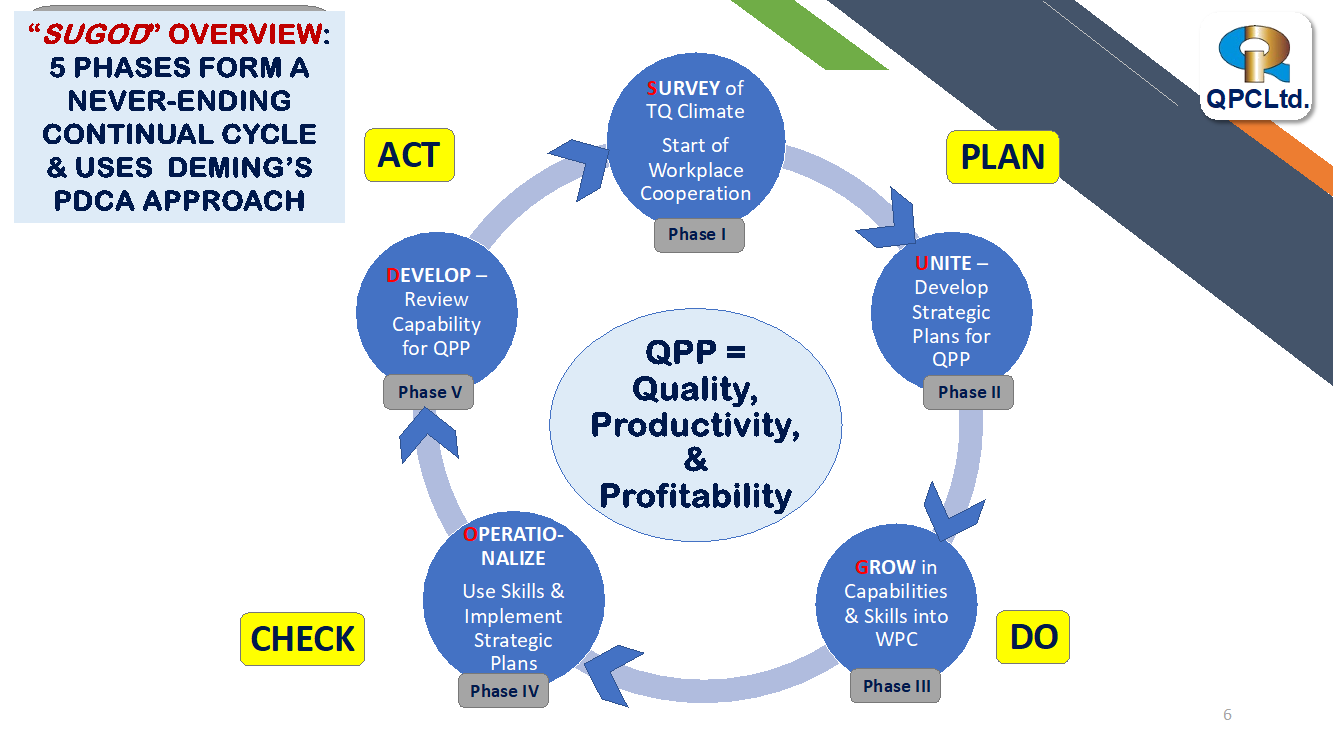

Fig.1. Phases of the SUGOD Quality Development Cycle

“SUGOD” QUALITY DEVELOPMENT CYCLE. Figure 1 presents a cyclic pattern in five (5) phases, which basically follows Deming’s famous PDCA (Plan Do Check Act), necessary to achieve continual quality improvement. Phase 1- SURVEY is involved with obtaining baseline information about the company’s major practices/resources such as the 5Ms (Manpower, Materials, Methods, Machines, Measurement). Data collected include both from a Climate Survey conducted and actual review of the company’s 5Ms. Based on the information obtained from Phase 1-SURVEY, the need to UNITE (Phase II) towards a common company direction clearly surfaces and thus, Phase II is focused on identification of opportunities for improvement. Such findings form the basis for the development of realistic strategic plans that identifies measurable goals in the form of Key Result Areas (KRAs). This also defines the specific improvement areas particularly those that pertain to employee competence which would lead to the realisation of the great importance of employee capability enhancement. This becomes the basic content of Phase III - GROW which underscores the importance of training needs identification necessary to enhance employee competence. In turn, the latter will ensure that set strategic goals will be achieved. One part of Phase III-Grow is the identification of the company’s growth factors and how these are to be achieved. Accomplishments obtained from Phases I-III are utilised for improvement of processes for implementation in Phase IV - OPERATIONALISE. This Phase is meant to employ the important changes necessary to ensure consistent quality and productivity in the company operations. Finally, all the baseline information and improvements done in Phases I-IV are fully reviewed to ensure movement towards the desired over-all improvement level. This should be properly planned in Phase V – DEVELOP so that when accurately implemented would lead to the company’s Growth and Stability. The four cycles covering Phases I to IV provide the foundation for the Company’s sustainable Growth. Hence, the cycles of improvement derived from each of the first four SUGOD Phases provide the first level improvement of the company. Furthermore, this forms the foundation for planning (Phase V-Develop) the second level of business success measured in terms of QPP to be achieved in another series of the three development cycles covering BASELINE, IMPROVEMENT and GROWTH or the acronym BIG.

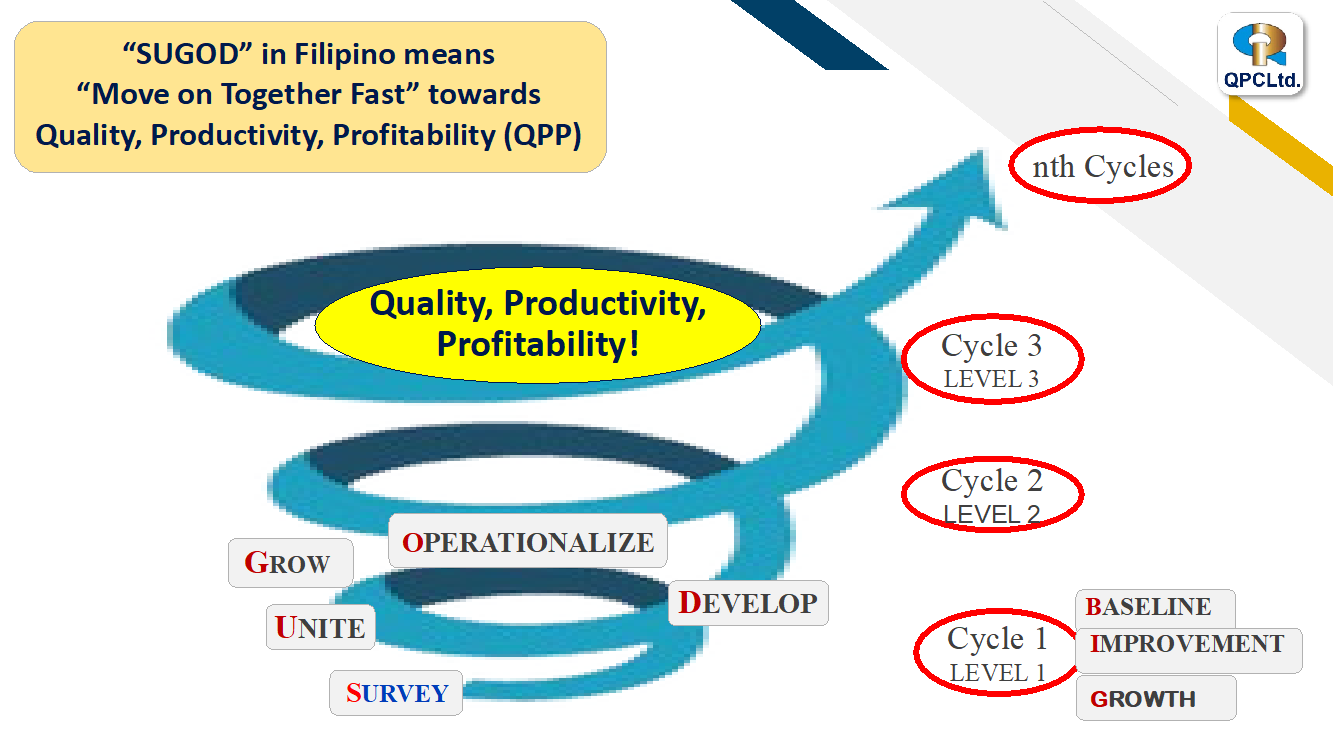

Fig. 2. Cycles of Improvement from Cycle 1: (BIG)- Baseline, Improvement, Growth

LEVELS OF QPP PER SUGOD CYCLE COMPLETION. Shown in Figure 2 are the LEVELS of growth and development of QPP in the Company with every cycle completed. The major goal of SUGOD for TQM is to provide the avenue for Total Quality Management to be eventually achieved at the shortest time possible. It is expected that for every SUGOD cycle completed, the company’s level of quality, productivity and profitability (QPP) moves up to a higher plain of business success. At this point, effective measures of progress in quantifiable terms should already be utilised by management and staff. Generally, at Phase IV, “statistical thinking” development is strongly encouraged and thus, measurement methods, as well as, basic statistical tools and techniques are introduced and utilised for the 4Ms being reviewed and subsequently improved. Such measures provide the basis upon which growth trends are observed and identification of weaknesses and strengths are also derived. Findings provide the groundwork upon which decisions are made to identify the focus of growth and development targets. The latter serve as the point of reference as the company moves on to a higher level of successful QPPs targeted to be achieved in another series of SUGOD cycles.

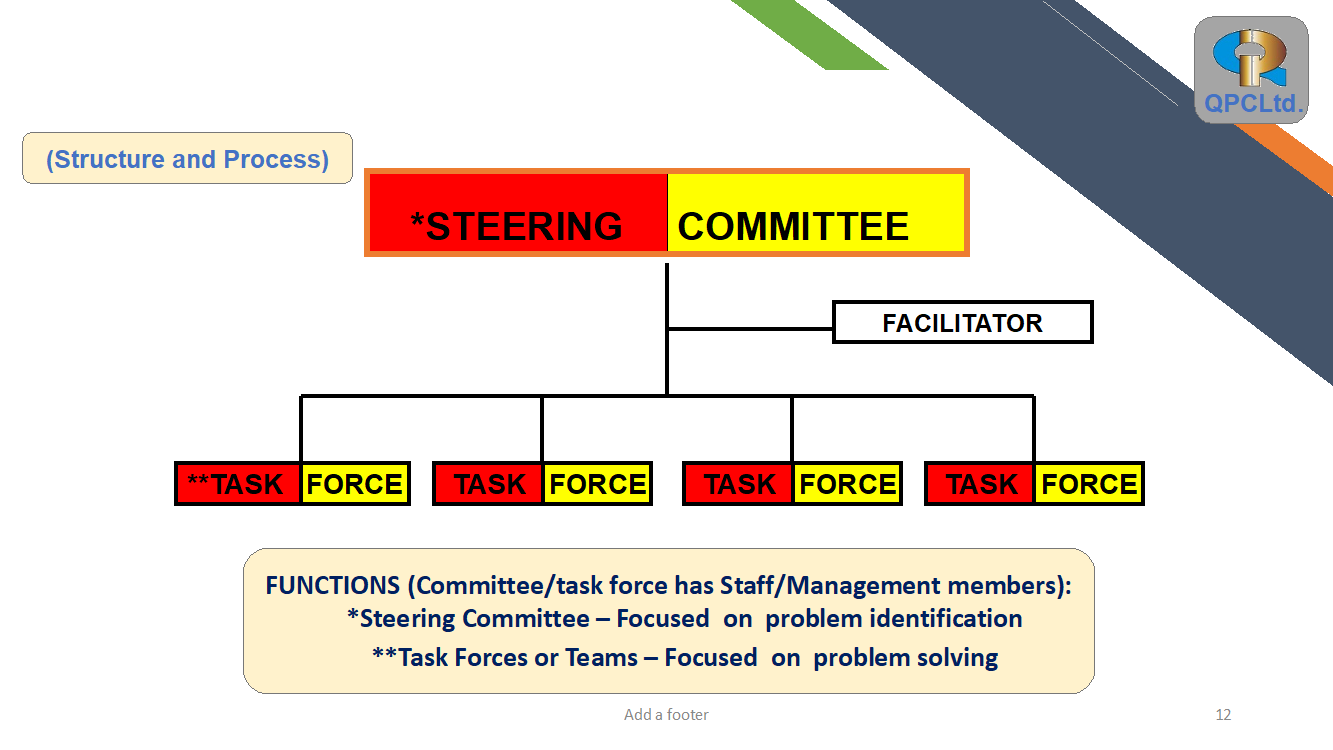

Fig. 3. The structure and process of the Workforce Steering Committee

Sustaining quality, productivity and profitability. The ultimate goal in the quest for Total Quality Management (TQM) is to have a sustainable progress towards the achievement of continual growth in Quality, Productivity and Profitability (QPP). One of the successful practices towards this end is the organisation of a Workforce Steering Committee (WSC), a major channel towards total quality, developed under the SUGOD for TQM approach. Figure 3 presents the structure and process of the WSC which requires Management (red color) and Staff (yellow) to jointly work together. The Steering Committee (SC) is composed of representatives from Management who are appointed by the Company Leader and from the Staff who are elected by fellow employees. They are expected to identify problems or areas needing improvement and the creation of Task Forces (TF) to work on them. The structure requires an external Facilitator especially at the start of WSC to provide guidance in the proper organisation and initial implementation of functions. The Task Force (TF) is a team of three (3) or more members also composed of Management and Staff and given the responsibility to solve problems or to lead in desired improvement activities both assigned by the SC. To ensure companywide participation in problem-solving: (a) the TF is disbanded as soon as their recommended problem solution is approved for implementation by the SC ; and (b) everyone in the company is required to be a TF member at least once in a year. Depending on the size of the organisation, a TF member cannot be a member twice as long as there are still employees who have not participated. The objective is for a companywide participation as members of TFs all year round.

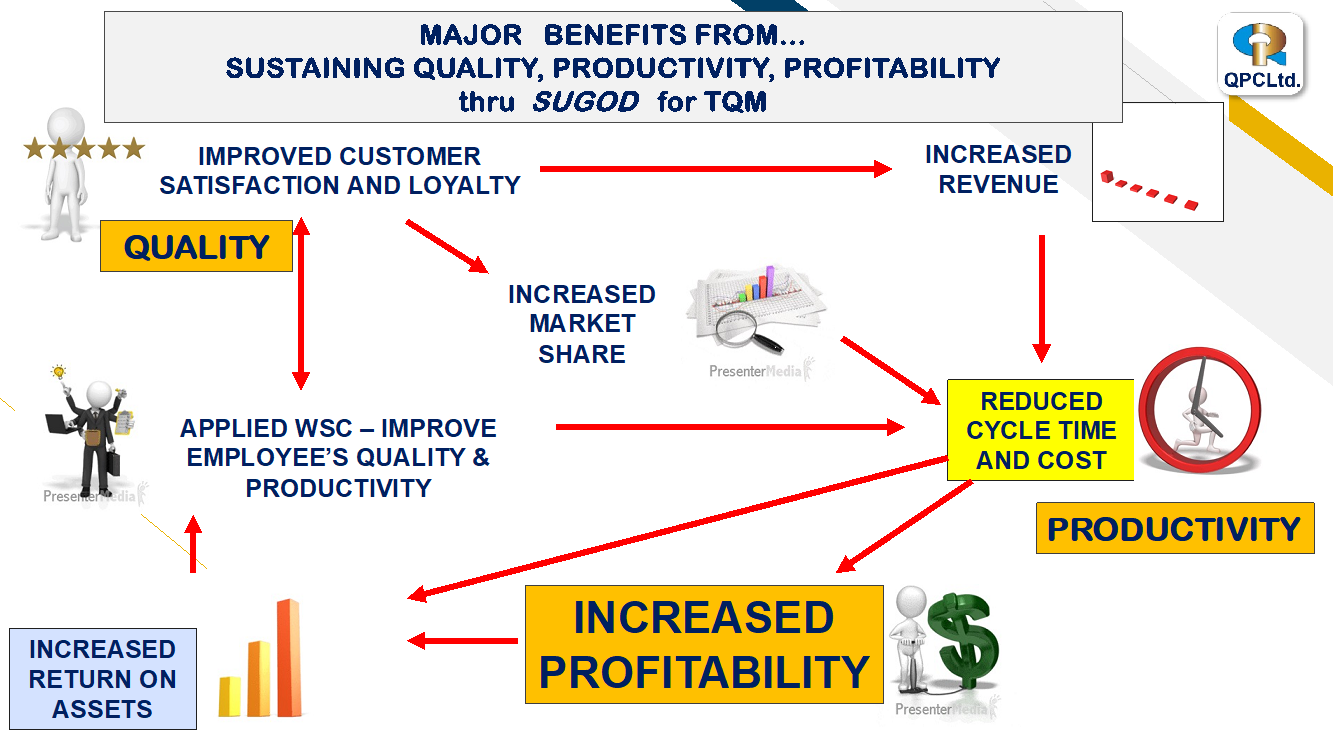

Fig. 4. The benefits obtained from sustaining quality, productivity and profitability

Role of WSC in sustaining QPP. The SC has a term of 3 years after which a new set of management and staff members is organised in the same manner and their practices continue to support the Company. Furthermore, while in WSC, the SC creates the TFs and disband them after task completion, the SC is also given the responsibility to create “Standing Committees”, with a 3-year tenure which is renewable. These committees are created to respond to employee-needs requiring long-term attention such as: (a) Employee Family Health and Welfare: (b) Children Education and Development and other needs to benefit the employees as well as their family and community. When the employees and their families are cared for by the company, the effect is generally towards enhancement of their performance at work. Likewise, this results to their improved contributions to quality and productivity, which in turn reduce production cost and improve customer satisfaction that ultimately leads to higher profitability. As long as WSC, a major creation of SUGOD for TQM, continues to actively perform their functions , sustainability of QPP is assured

Overall effect of WSC on QPP sustainability under SUGOD for TQM. When fully activated, the WSC becomes the moving spirit of the Company providing assurance of everyone’s sustained participation either in problem-solving activities or in major areas which promote the improvement of quality, productivity and profitability. The detailed description of how WSC works towards a sustainable TQM is discussed in Gatchalian (2022). Figure 4 provides a graphic presentation of the effects of quality and productivity on increasing profitability.

Conclusion

An approach with the acronym SUGOD (Survey, Unite, Grow, Operationalise, Develop) was introduced as a credible means towards the achievement of Total Quality Management (TQM). The major factor which greatly contributed to sustainability of the TQM quest for quality, productivity profitability (QPP) was the creation of the Workforce Steering Committee (WSC). This provided the avenue for assurance of continual improvement through the joint efforts of Management and Staff working together to achieve both total employee involvement in the quest for continuous improvement towards the achievement of QPP.

References

Bostingl, John Jay. 1997. QWL. National governor’s conference on quality in education. November 8-11, 1997. Dearborn, MI. p. 459-476

Corrigan, James P. 1995. “The Art of TQM”. Quality Progress, July 1995. P61-64. American Society for Quality (ASQ), 611 E. Wisconsin Ave. P.O. Box 3005, Milwaukee, WI 53201 –3005

Gatchalian, M.M. 2015. Filipino “SUGOD” (move-on together): Roadmap/Framework for a Sustainable Quality Improvement. Proceedings. 1st International Academy for Quality World Quality Forum (IAQ-WQF). October 26-28, 2015 . Kempinski Hotel, Budapest, Hungary,

Gatchalian. Miflora M. 2022. Workforce Steering Committee: Key to Sustainability of Total Quality. Proceedings . 27th APQO International Conference 2022. Colombo Sri Lanka.

Mamon. Mario O. 2014. Workplace Cooperation. The LMC (now WPC) and EKI’s Turn-around Experience. Proceedings. 2nd National Seminar Workshop. U.P. ISSI. University of the Philippines, Diliman, Quezon City

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login