Precision is almost taken for granted. Indeed, the volatility of the market has intensified customers' interest in flexible grinding and hard turning solutions that allow them to address future changes.

Flexibility is also a key characteristic of our machines and solutions and it is achieved through various means, including modular design, software, versatile machining capabilities, integration with automation systems, and fast changeovers.

Here are some examples of flexibility that you can find in our centerless, vertical, internal and external grinding machines.

Estarta - Centerless grinding machine (read more)

- Motorised wheel cover opening

- OptiDress: up to 70% reduction in non-productive dressing time

- Automatic taper correction

- Automatic workrest blade clamp and height positioning

VG - Vertical grinding machine with moving table (read more)

- System 3R for clamping parts out of the machine, optimising part changeover times and subsequent adjustment

- C-axis: customised quick change clamping system

- Dressing system: customised dressing turret

- B-axis: robot with an endless portfolio of grinding wheels, turning, measuring, deburring, drilling....

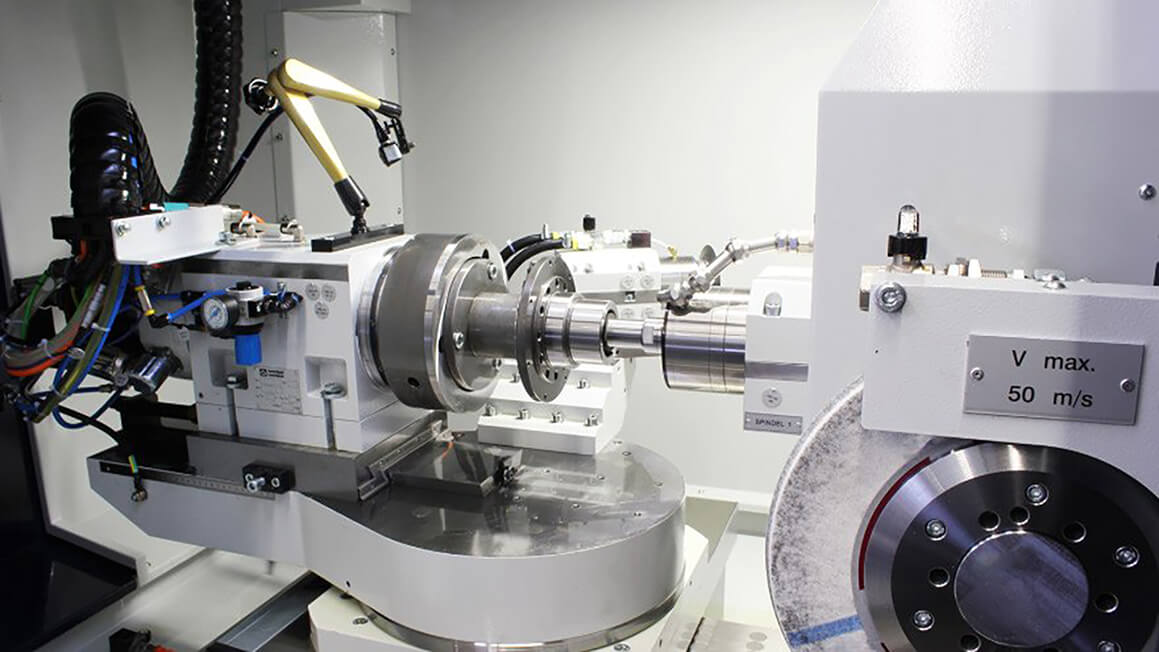

IRD - Internal, external and radius grinding machine (read more)

- Customised quick change clamping system

- Workhead: swivelling B0 and B1 axis for grinding a wide range of workpiece types

- Wheel and part auto set-up

- Radius, non-round, threads and jig grinding operations, all in one HMI

CG - Compact grinding machine for high production (read more)

- Automatic set-up for dressing a new grinding wheel

- Automatic wheel changing cycle

- Z and X axis reference block for wheel touch offset to avoid manual setting

- Mobile wide range in-process measuring system with no need to do new set-ups

- Wide range tailstock (quill ranges from 80 to 170 mm)

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login