Polyplastics Co. Ltd. has developed unique CAE analysis technology that predicts the occurrence of vacuum voids in injection moulded products made of DURACON® POM. This new CAE tool can predict the risk of voids forming before creating the mould, and thus helps to reduce trial samples, shorten the development cycle, and reduce energy usage.

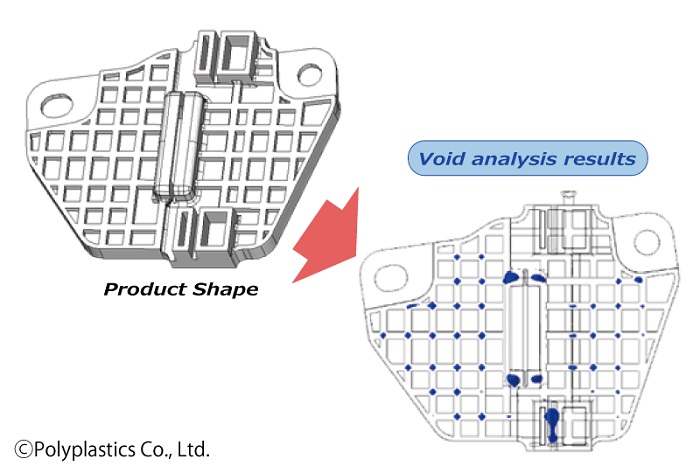

Polyplastics’ void prediction technology takes into consideration changes in variables including temperature and pressure during the resin solidification process when using DURACON® POM. This technology verifies the shape, moulding conditions, and effects of changes in the gate position in advance, and visualizes the size of voids as well as the positions in which they will form.

One type of moulding defect is hollow pockets, called voids, which form near the centre of thick injection moulded products. Parameters such as volume shrinkage that is produced as output from flow analyses had conventionally been used for void prediction, but the accuracy of this method has been problematic since the actual phenomenon can’t be recreated.

The new void prediction technology is an entirely new method that links flow analysis with structural analysis to predict the formation of voids according to strain arising inside moulded products, taking into consideration mould shrinkage, elastic modulus, and distribution of pressure in the resin solidification process. Since it can predict voids with high accuracy before the mould is built, this technology promises to reduce the development cycle, cut down on product development costs, and reduce energy consumption for simulations.

Polyplastics is offering the new technology as part of its overall technical support for current POM customers.