Walter is expanding its Tiger·tec® Gold range with two new PVD-coated grades, WKK25G and WSM35G. This is the Tübingen-based company's response to the persistent trend towards steels with difficult cutting properties and stainless steels, such as in the energy and aviation industries. The WKK25G is designed to machine cast iron workpieces. It meets the most stringent requirements for process reliability (e.g. in the automotive sector) and is suitable for highly abrasive materials and difficult operating conditions, such as interrupted cuts or for wet machining. The WSM35G can be used universally with ISO materials from groups M and S (e.g. austenitic stainless steel or nickel-based alloys). It is designed to enable users to achieve long tool life, especially under good conditions and during wet machining.

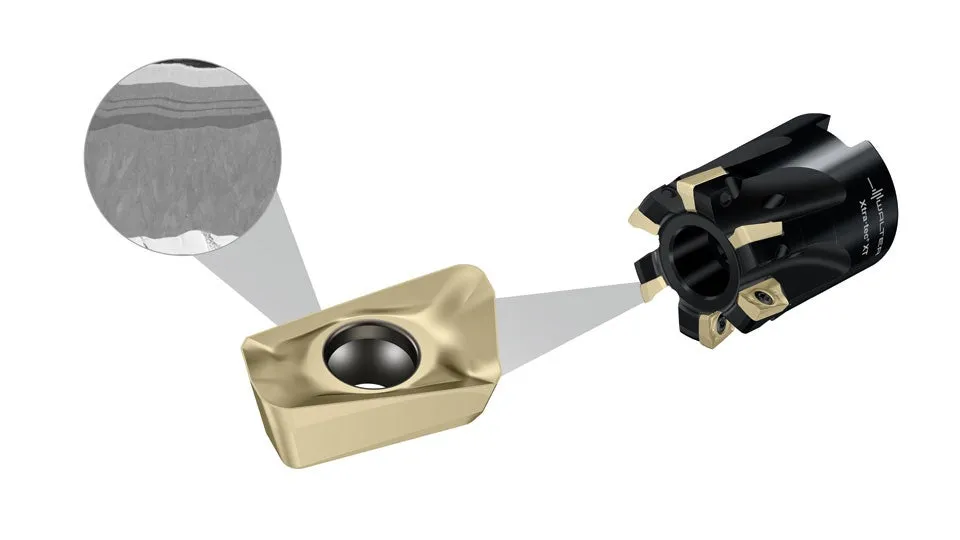

Both new developments use the same technical platform as their successful predecessor: The Walter Tiger·tec® Gold grade WSP45G. Its perfect balance between wear resistance and toughness is based on the only PVD Al2O3 technology of its kind in the world to date with a multi-layer structure: TiAlN layer for high wear resistance, Al2O3 for high temperature resistance and ZrN top layer for minimised friction and best wear detection. A new coating generation that ensures excellent cutting edge stability and therefore tool life, as well as high process reliability, even in complex applications. Successful applications include engine housing parts made from Inconel or titanium in aircraft construction and machining engines and turbochargers in automotive construction. In these applications, Walter managed to increase the tool life compared to previous cutting tool materials by 30% or more.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login