At Plast Eurasia, scheduled from December 3-6, Arburg is expected to stress its role as an all-around partner to the plastics processing industry via its range of products extending from the additive manufacturing of one-off parts and small-volume batches from qualified standard granulate to the automated injection molding of mass-produced items.

Two examples of this application range is the first-time presentation of the Freeformer to the Turkish market, while an automated, high-speed IML injection molding application with a hybrid Allrounder will demonstrate its performance capability aimed at the packaging sector.

Engin Malcan, Managing Director at Arburg Turkey, said that Arburg is well-positioned to meet the growing requirements of the Turkish market with innovative technology. "As the second-largest plastics manufacturer in Europe, Turkey is increasingly demanding the kind of high-end solutions that we can provide. Europe meets Asia at the Plast Eurasia and the Istanbul Exhibition Centre, providing the ideal opportunity to present our technology in detail and to make contact with customers and other interested parties."

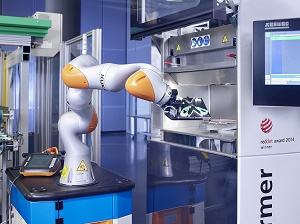

The trade exhibition is celebrating its 25th anniversary this year and thus provides an ideal location for the launch of Freeformer in Turkey. Freeformer is Arburg's innovative system for additive manufacturing. It was developed by Arburg on the basis of decades of expertise in machine construction and plastics processing as well as practical knowledge of the needs of the plastics processing industry. The system uses the patented Arburg Plastic Freeforming (APF) to produce fully functional plastic parts from inexpensive standard plastic granulates based on 3D CAD data without a mold - just one of the advantages over other additive manufacturing processes. At the exhibit, a special support material will be used as the second component which makes it possible to achieve unusual or complex part geometries.

Another demonstration is the automated production cell for producing 0.8-liter containers with handles that is specificially tailored to the dynamic packaging market. The hybrid Allrounder 720H with 2,900 kN clamping force and size 1300 injection unit used for thin-walled production comes in a special "Packaging" version. The two-cavity mold and the automation system for inserting the labels and removing and stacking the thin-walled moulded parts come from Turkish IML specialists and Arburg cooperation partners Erkoҫ and Roboplas from Istanbul. The cycle time is around 4.9 seconds.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login