Let’s explore very large-scale 3D printing with pellet materials. There are cost effective advantages to printing with pellets. By reducing material costs significantly, it enables you to undertake ambitious large-scale projects without breaking the bank. Pellet materials are more affordable compared to traditional filament spools. Pellets make 3D printing more economically viable for large-scale projects and mass production.

In general, large scale 3D printing allows for faster production times compared to traditional methods. When combined with efficient pellet materials, you can accelerate your prototyping and manufacturing processes, leading to quicker turnaround times and shorter time-to-market for your products. Pellets can be heated and melted more rapidly than filament, resulting in faster printing speeds.

Very large-scale 3D printing with pellet materials offers a vast range of applications. From architectural models and furniture to industrial prototypes and custom components, the possibilities are endless for very large scale production. Whether you need flexibility, durability, or heat resistance, affordable pellet materials offer a diverse range of characteristics to meet your specific project requirements.

Pellet materials come in a diverse range of options, including various plastics, composites, and even metal-filled pellets. This versatility allows for printing parts with specific mechanical, thermal, or aesthetic properties to meet various application requirements. Also creating custom material blends opens up possibilities for engineering with unique material properties tailored to specific project needs.

Using pellet materials can contribute to eco-friendly practices. Many pellet materials are recyclable and reduce waste during the 3D printing process, making your projects more sustainable, allowing for a closed-loop approach to 3D printing.

Unlock the potential of large-scale 3D printing with pellet materials to create life-sized objects and structures that were previously challenging or expensive to produce. Reach out to Ugogo3D to learn more about large scale 3D printing.

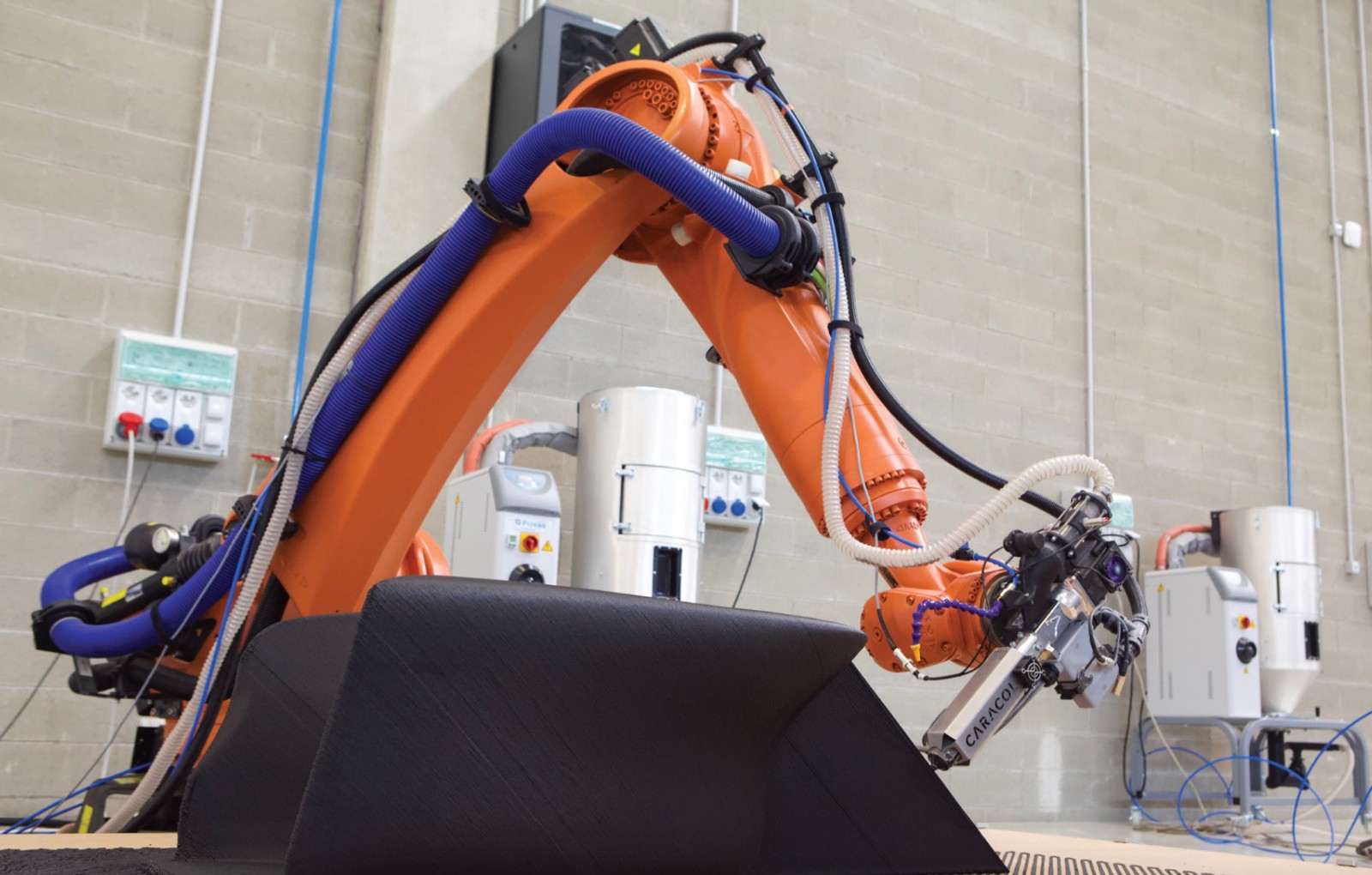

CARACOL- The perfect choice for pellet extrusion

The Caracol Heron Robotic 3D printers offer a range of advantages that make them a compelling choice for various applications. Here are some of the key advantages:

Caracol 3D printers are highly versatile and can print in a wide variety of pellet materials, including plastics, ceramics, and composites. Caracol is even introducing a Direct Energy Deposition (DED) metal solution later this year. The material versatility allows for the creation of diverse and complex geometries on a very large scale to meet different industry needs.

The Caracol Heron printers create life-sized objects, architectural structures, and other sizable components. This capability is especially beneficial for projects that require substantial dimensions. The Heron is available in: 2 meter, 3 meter and 4 meter systems and offers a rail system allowing printing of unlimited length.

Being robotic, Caracol’s printers are mobile and can operate in various environments. They can be deployed in manufacturing facilities, construction sites, or even remote locations, making them adaptable to different production requirements.

One of the most amazing features of Caracol 3D printers is its advanced control systems and high-quality sensors that achieve precise and accurate printing. This ensures that the final products meet tight tolerances and exact specifications. Other robotic systems can be difficult to use but not the Caracol. The best part is that it is easy to use which aides in productivity.

The robotic arm of Caracol printers can move in multiple axes, enabling the printing of intricate and complex geometries that may be challenging for traditional 3D printers. This capability expands the design possibilities for engineers and designers.

With the ability to operate continuously and at high speeds, Caracol robotic 3D printers can significantly reduce production time compared to conventional manufacturing methods. The Caracol can Print up to 40 kilograms of material per hour which is exponentially faster than large scale filament 3D printers.

The precise control and pellet usage of Caracol printers help reduce material waste during the printing process, leading to cost savings and a more sustainable manufacturing approach.

Caracol robotic 3D printers provide a comprehensive set of advantages that enhance efficiency, precision, and flexibility in the additive manufacturing process. Their ability to print large-scale objects, work with various materials, and operate autonomously makes them a valuable tool for diverse applications, from rapid prototyping to large-scale production in various industries.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login