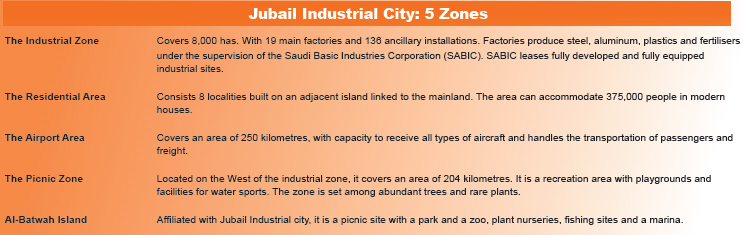

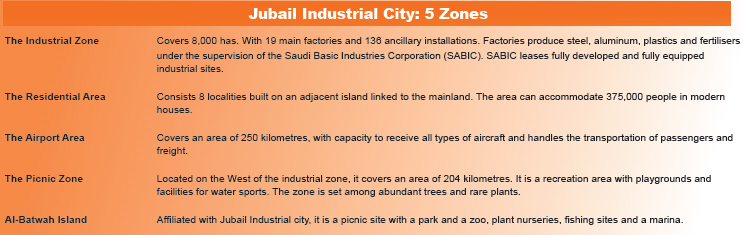

Al Jubail, a city in the Eastern province on the Persian Gulf coast of Saudi Arabia has now taken a new chapter in its history. From a small fishing village, the city in 1975 began its transformation after it was designated as a site for a new industrial city by the Saudi government. Since then, rapid industrialisation has taken place and now, the industrial city is known for being the largest industrial complex of its kind in the world - serving as most appropriate location for various petrochemical plants, fertilser plants, steel works, industrial port and a huge number of support industries. It boasts of the who's who in the industrial world and their massive projects have created a powerful industrial location that would definitely turn Al Jubail into one of the most sought- after areas to do business. To date, the Jubail Industrial City is Saudi Arabia's and the world's biggest industrial centre, hosting over 160 industrial enterprises and home to almost 170,000 full-time residents. It is a complete city with all necessary infrast ructure, hous ing, shopping, educational and medical facilities required to support its present population of almost 100,000 people. Moving on to a second industrial area

Bechtel has been working on the Jubail Industrial City project for the past 30 years and construction is still going on that the project has been tagged as the largest civil engineering project in the world today. In 2004, the Royal Commission for Jubail and Yanbu tapped the company to manage Jubail II, a $3.8 billion expansion of the city's industrial and residential areas. Jubail II will add a second industrial area to serve as location to 22 new primary industries. The project also calls for the expansion of King Fahd Industrial Port, pipeline refurbishment, increasing capacity of the cooling system, and new desalination plants to support these additional industries. The Jubail Industrial City II is divided into four phases with construction to span 22 years. The four phases is expected to cost around SR 14 billion. Phase 1 is to consist of eight blocks of industries each with several industrial plants. Phase II is expected to include four blocks of petrochemical industries plus areas to accommodate secondary and support industries. Phase III is targeted to have an additional three blocks of petrochemical industries along with secondary and support industries. Phase IV would have four industrial blocks for aluminum and other smelting plants, including additional areas for secondary industries. All the petrochemical industries planned for Jubail II are expected to receive their natural gas feedstocks from the Saudi Aramco Uthmaniyah project area.

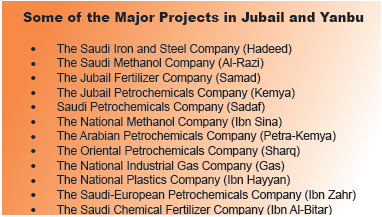

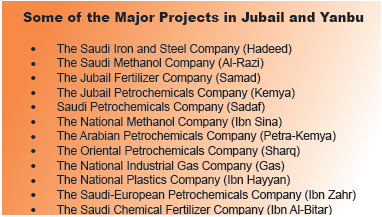

Site for world's biggest industrial projects The Al-Jubail Industrial City is set to leave its mark in the history for being the location of the world's biggest industrial projects ?with most of them benefiting the region's rapidly growing plastics industry. The Al-Jubail Petrochemical Company (Kemya), a joint venture between SABIC and ExxonMobil owns an ethylene and polyethylene plant in the industrial city. As part of the expansion, capacity was added to the existing linear LDPE plant expanding it from 615,000 tonnes per year to 850,000 metric tonnes per year. Also, a new 218,000 metric-tonne-per-year LDPE plant was constructed. This plant, Saudi Arabia's first high pressure LDPE plant, is based on ExxonMobil proprietary technology. Ibn Zahr's polypropylene plant is located in Yanpet, near Al Jubail. The facility is next to the Saudi European Petrochemical Company's existing production plant and close to the supplier of its feedstock The plant is part of the polypropylene plant expansion programme by SABIC with production capacity of 500,000 tonnes per annum. Dow Chemical Compan

Highsnobiety Sneakers Al Jubail, a city in the Eastern province on the Persian Gulf coast of Saudi Arabia has now taken a new chapter in its history. From a small fishing village, the city in 1975 began its transformation after it was designated as a site for a new industrial city by the Saudi government. Since then, rapid industrialisation has taken place and now, the industrial city is known for being the largest industrial complex of its kind in the world - serving as most appropriate location for various petrochemical plants, fertilser plants, steel works, industrial port and a huge number of support industries. It boasts of the who's who in the industrial world and their massive projects have created a powerful industrial location that would definitely turn Al Jubail into one of the most sought- after areas to do business. To date, the Jubail Industrial City is Saudi Arabia's and the world's biggest industrial centre, hosting over 160 industrial enterprises and home to almost 170,000 full-time residents. It is a complete city with all necessary infrast ructure, hous ing, shopping, educational and medical facilities required to support its present population of almost 100,000 people. Moving on to a second industrial area

Al Jubail, a city in the Eastern province on the Persian Gulf coast of Saudi Arabia has now taken a new chapter in its history. From a small fishing village, the city in 1975 began its transformation after it was designated as a site for a new industrial city by the Saudi government. Since then, rapid industrialisation has taken place and now, the industrial city is known for being the largest industrial complex of its kind in the world - serving as most appropriate location for various petrochemical plants, fertilser plants, steel works, industrial port and a huge number of support industries. It boasts of the who's who in the industrial world and their massive projects have created a powerful industrial location that would definitely turn Al Jubail into one of the most sought- after areas to do business. To date, the Jubail Industrial City is Saudi Arabia's and the world's biggest industrial centre, hosting over 160 industrial enterprises and home to almost 170,000 full-time residents. It is a complete city with all necessary infrast ructure, hous ing, shopping, educational and medical facilities required to support its present population of almost 100,000 people. Moving on to a second industrial area  Bechtel has been working on the Jubail Industrial City project for the past 30 years and construction is still going on that the project has been tagged as the largest civil engineering project in the world today. In 2004, the Royal Commission for Jubail and Yanbu tapped the company to manage Jubail II, a $3.8 billion expansion of the city's industrial and residential areas. Jubail II will add a second industrial area to serve as location to 22 new primary industries. The project also calls for the expansion of King Fahd Industrial Port, pipeline refurbishment, increasing capacity of the cooling system, and new desalination plants to support these additional industries. The Jubail Industrial City II is divided into four phases with construction to span 22 years. The four phases is expected to cost around SR 14 billion. Phase 1 is to consist of eight blocks of industries each with several industrial plants. Phase II is expected to include four blocks of petrochemical industries plus areas to accommodate secondary and support industries. Phase III is targeted to have an additional three blocks of petrochemical industries along with secondary and support industries. Phase IV would have four industrial blocks for aluminum and other smelting plants, including additional areas for secondary industries. All the petrochemical industries planned for Jubail II are expected to receive their natural gas feedstocks from the Saudi Aramco Uthmaniyah project area.

Bechtel has been working on the Jubail Industrial City project for the past 30 years and construction is still going on that the project has been tagged as the largest civil engineering project in the world today. In 2004, the Royal Commission for Jubail and Yanbu tapped the company to manage Jubail II, a $3.8 billion expansion of the city's industrial and residential areas. Jubail II will add a second industrial area to serve as location to 22 new primary industries. The project also calls for the expansion of King Fahd Industrial Port, pipeline refurbishment, increasing capacity of the cooling system, and new desalination plants to support these additional industries. The Jubail Industrial City II is divided into four phases with construction to span 22 years. The four phases is expected to cost around SR 14 billion. Phase 1 is to consist of eight blocks of industries each with several industrial plants. Phase II is expected to include four blocks of petrochemical industries plus areas to accommodate secondary and support industries. Phase III is targeted to have an additional three blocks of petrochemical industries along with secondary and support industries. Phase IV would have four industrial blocks for aluminum and other smelting plants, including additional areas for secondary industries. All the petrochemical industries planned for Jubail II are expected to receive their natural gas feedstocks from the Saudi Aramco Uthmaniyah project area.  Site for world's biggest industrial projects The Al-Jubail Industrial City is set to leave its mark in the history for being the location of the world's biggest industrial projects ?with most of them benefiting the region's rapidly growing plastics industry. The Al-Jubail Petrochemical Company (Kemya), a joint venture between SABIC and ExxonMobil owns an ethylene and polyethylene plant in the industrial city. As part of the expansion, capacity was added to the existing linear LDPE plant expanding it from 615,000 tonnes per year to 850,000 metric tonnes per year. Also, a new 218,000 metric-tonne-per-year LDPE plant was constructed. This plant, Saudi Arabia's first high pressure LDPE plant, is based on ExxonMobil proprietary technology. Ibn Zahr's polypropylene plant is located in Yanpet, near Al Jubail. The facility is next to the Saudi European Petrochemical Company's existing production plant and close to the supplier of its feedstock The plant is part of the polypropylene plant expansion programme by SABIC with production capacity of 500,000 tonnes per annum. Dow Chemical CompanHighsnobiety Sneakers

Site for world's biggest industrial projects The Al-Jubail Industrial City is set to leave its mark in the history for being the location of the world's biggest industrial projects ?with most of them benefiting the region's rapidly growing plastics industry. The Al-Jubail Petrochemical Company (Kemya), a joint venture between SABIC and ExxonMobil owns an ethylene and polyethylene plant in the industrial city. As part of the expansion, capacity was added to the existing linear LDPE plant expanding it from 615,000 tonnes per year to 850,000 metric tonnes per year. Also, a new 218,000 metric-tonne-per-year LDPE plant was constructed. This plant, Saudi Arabia's first high pressure LDPE plant, is based on ExxonMobil proprietary technology. Ibn Zahr's polypropylene plant is located in Yanpet, near Al Jubail. The facility is next to the Saudi European Petrochemical Company's existing production plant and close to the supplier of its feedstock The plant is part of the polypropylene plant expansion programme by SABIC with production capacity of 500,000 tonnes per annum. Dow Chemical CompanHighsnobiety Sneakers

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login