For the manufacture of superior quality masterbatches with exceptional efficiency and cost-effectiveness, Coperion provides an all-inclusive production system. This comprehensive package incorporates an STS 35 Mc11 twin screw extruder, a Coperion K-Tron S60 volumetric single screw feeder, and an SP 100 EN strand pelletizer from Coperion Pelletizing Technology.

Every single process step within the system is impeccably synchronized for seamless integration and maximum productivity. The system is replete with numerous features designed to optimize the masterbatch processing efficiency. Notably, its design promotes ease of cleaning for quick recipe modifications. Thanks to an attractive price-performance ratio, the Coperion masterbatch system ensures a quick return on investment.

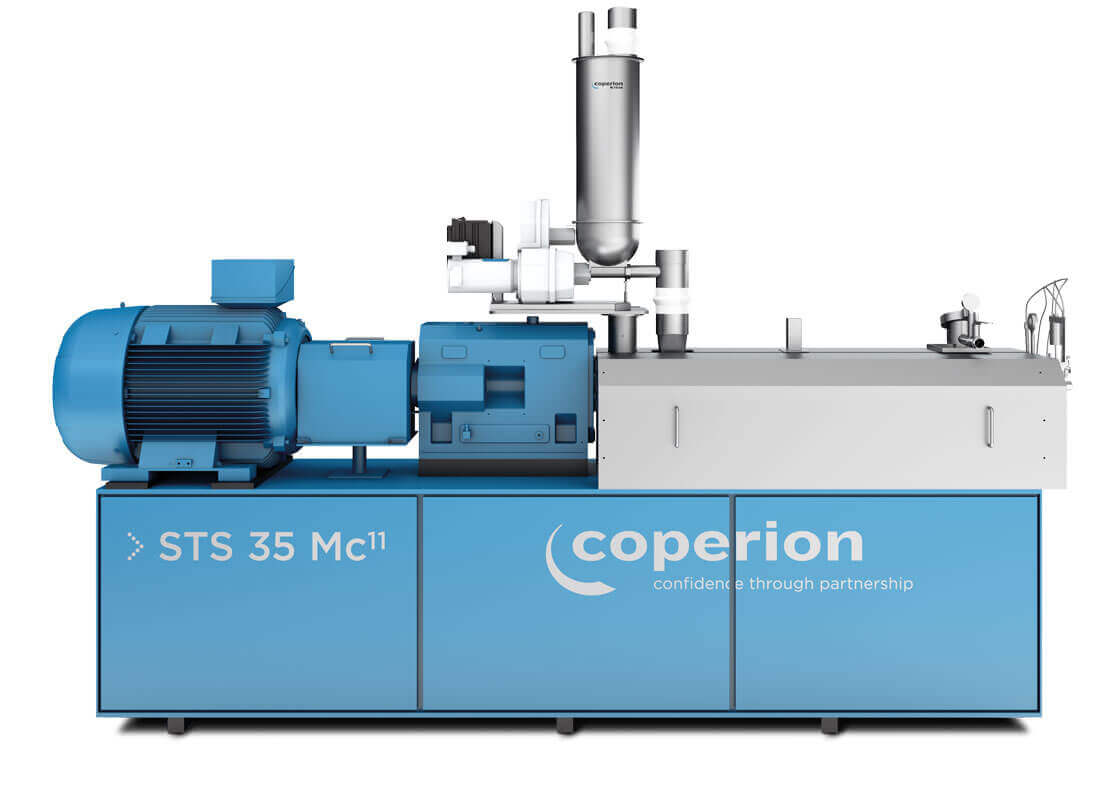

Twin screw extruder STS 35 Mc11 in masterbatch design

Screw diameter of 35 mm [1.38 in]

Max. specific torque of 11.3 Nm/m³

Do/Di = 1.55 (outer to inner screw diameter) - across the entire STS Mc11 series, identical to Do/Di of the ZSK Mc18 series

Throughput rates up to 300 kg/h

Main drive, Coperion gearbox, safety coupling and control cabinet from European manufacturers

Compact design, dust-free and easy to clean thanks to smooth surfaces

Water supply and electrical wiring are integrated and physically separated in the base frame

Feed hopper in quick-change design for fast disassembly

Self-cleaning, co-rotating twin screws with tight screw profile for fast product and color changes

Die head in masterbatch design: easy to clean and features improved heating system and optimized flow geometry

Attractive price-performance ratio

Short delivery times between 4-5 months

Over 350 systems installed worldwide

S60 volumetric single screw Coperion K-Tron feeder

Continuous operation for consistent, accurate feeding of ingredients

Gentle product handling of the horizontal agitator and feeding screw

Interchangeable feeding tools

All parts in contact with the product made of stainless steel

Fast disassembly and very good cleanability of the feeder

Strand pelletizer SP 100 EN

One-side bearing Working width 100 mm [3.94 in]

Up to 20 strands

Throughputs up to 650 kg/h - depending on the recipe

Easy access for quick cleaning

Vibration isolation

Many other useful options, such as pellet length regulation, drive for top feed roll, die head cooling, transmission signal to extruder control, customized base frame, etc.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login