A beef carcass trimming system has delivered inc reased yield and throughput with full traceability

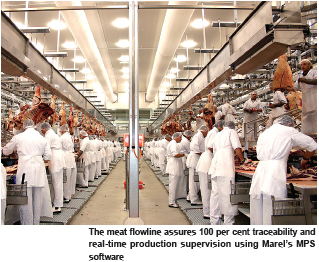

A beef carcass trimming system has delivered inc reased yield and throughput with full traceabilityWITH increasing demands for full traceability along with greater efficiency, meat processor Gilde Norge BA decided to modernise their operations at Throndheim and Egersund in Norway. Whilst the beef processing plant at Gilde Vest Egersund was as efficient as any other that used traditional methods of deboning and trimming, all that changed when traceability became imperative in the meat industry. Their choice was a complete Marel trimming flowlines and traceability systems with continuous flow throughout the process. Two of the most important facets of the new meat flowline are 100 per cent traceability and real-time production supervision using Marel's MPS software. This technology allows total control over production, quality and yield, while plant managers also have a real-time overview of each individual carcass going through the plant, enabling traceability back to the farm on the one hand, and back to each worker on the other. In other words, from incoming raw material to packing and inventory. Operations manager Inge Mykelburst has run the new plant in Egersund from the beginning. "When we decided to install a new trimming system, there were many factors that we needed to consider: increased food safety with traceability was one of the most important ones," says Mr Mykelburst. "The Marel trimming flowline is the core equipment that helped us achieve that goal." Trimming line ensures food safety The trimming flowline is fed with hind- or forequarters that are scanned into the system, and the data is entered into the Marel MPS production control software that runs the process. The product is monitored every step of the way making it possible to trace it back to it's origin. Once a quarter has been deboned, it moves through a Marel registration station on its way to trimming.

"The Marel Trimming line has worked very well for us. We're happy about both the way we can monitor yield and throughput in real-time - and trace each individual piece of meat back to its origin," says Mr Mykelburst. "Which is one of the most important issues of food safety in the meat processing industry." When a quarter enters a trimmer's station, the computer monitor automatically displays instructions on what to cut and trim. After cutting the pieces, the trimmer guides them to their designated chutes. The meat is then transported on a conveyor to a flow scale that weighs each piece, and then allocates it to the Marel grader. After grading the meat is either vacuum packed and ready for shipment, or moved to the beef aging room, which is automatically controlled with an advanced inventory system from Marel's Danish subsidiary, Carnitech. The final products has a bar code that has information on origin, trimmer ID and process date and treatment as well as other product information. New methods catch on More than a year on since installation, the innovative trimming system at Gilde Vest has run very efficiently. "We know that quality doesn't come cheap, but we believe we have the best system available for the price we paid. And it's proven very effective: in one year we've had only one day of downtime, which is better than I could have ever hoped for," says Mr Mykelburst. Initially the system changed the way each worker operated. The new method required an adjustment period, but today the trimmers can't imagine ever having done things differently. "Our trimmers had to adapt to a new method of working, but to them it is a much better way. Before, they had all the meat stacked in front of them, and had to work on just one, large trimming table," explains Mr Mykelburst. "Now, each trimmer gets a quarter delivered to his station, and finishes it before the next one is delivered. "This improves badidas Mutator

"The Marel Trimming line has worked very well for us. We're happy about both the way we can monitor yield and throughput in real-time - and trace each individual piece of meat back to its origin," says Mr Mykelburst. "Which is one of the most important issues of food safety in the meat processing industry." When a quarter enters a trimmer's station, the computer monitor automatically displays instructions on what to cut and trim. After cutting the pieces, the trimmer guides them to their designated chutes. The meat is then transported on a conveyor to a flow scale that weighs each piece, and then allocates it to the Marel grader. After grading the meat is either vacuum packed and ready for shipment, or moved to the beef aging room, which is automatically controlled with an advanced inventory system from Marel's Danish subsidiary, Carnitech. The final products has a bar code that has information on origin, trimmer ID and process date and treatment as well as other product information. New methods catch on More than a year on since installation, the innovative trimming system at Gilde Vest has run very efficiently. "We know that quality doesn't come cheap, but we believe we have the best system available for the price we paid. And it's proven very effective: in one year we've had only one day of downtime, which is better than I could have ever hoped for," says Mr Mykelburst. Initially the system changed the way each worker operated. The new method required an adjustment period, but today the trimmers can't imagine ever having done things differently. "Our trimmers had to adapt to a new method of working, but to them it is a much better way. Before, they had all the meat stacked in front of them, and had to work on just one, large trimming table," explains Mr Mykelburst. "Now, each trimmer gets a quarter delivered to his station, and finishes it before the next one is delivered. "This improves badidas Mutator

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login