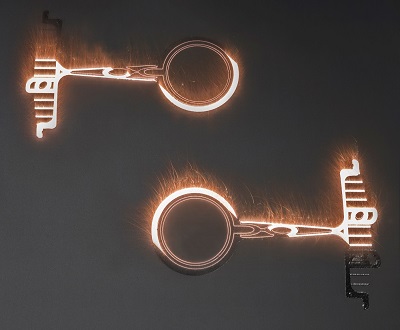

Bionic cabin holder “bracket” of the Airbus A350 XWB made of titanium, manufactured using the LaserCUSING process (Image courtesy of: Composing Ansgar Pudenz / German Future Prize)

Key words include: functional integration, lightweight construction potential, bionics and topology, conservation of resources, waste reduction, geometrical freedom, single shot production, reduction of assembly work, timely production, also "on-demand" and improvement of the cost structure, e.g. by unmanned manufacturing 24 hours a day. The laser melting process has been made first choice in numerous sectors in relation to conventional machining strategies by the current challenges posed by manufacturing. According to manufacturing experts, automation, quality, a wide range of materials, integration in the production environment and potential build speeds are essential characteristics of additive manufacturing in the digital era. Additive manufacturing in a digital process chain is consistently based, not least, on the "Industry 4.0" strategy.

Significance of laser melting to aircraft construction

Laser melting with metals is gaining in significance in aircraft construction as part of an additive manufacturing strategy. Here too, the typical reasons for the selected process are quicker throughput times, more cost-effective components and previously unknown freedom of design. Two new key words, "lightweight" and "bionics" point to an emerging trend: The design approaches of developers in aircraft construction are changed by an additive process. In terms of aircraft design, future components will be able to absorb specific lines of force and yet still be able to fulfill the demands of a lightweight construction approach. In general, laser melting technology is capable of manufacturing safety-related components that are even better, lighter and more durable than conventional components manufactured today. Moreover, the material properties are slightly different.

Prof. Dr.-Ing. Claus Emmelmann, CEO, Laser Zentrum Nord GmbH, Hamburg, said, "Materials produced using laser additive manufacturing have greater rigidity while, at the same time, less ductility; however this can be enhanced with the right heat treatment."

Furthermore, the process is distinguished by sustainability and resource conservation with simultaneous improvements to the cost structure.

Geometrical freedom and lightweight construction potentials as driving factors

The arguments for the laser melting of metals in aircraft construction are geometric freedom and weight reduction. The "lightweight construction" approach is intended to help airlines operate their aircraft more economically. The achievable weight reduction results in a tendency towards lower fuel consumption or the potential to increase load capacities of aircraft. A new aircraft design requires thousands of flight test installation (FTI) brackets, produced in very small quantities. Additive "layer manufacturing" allows designers to come up with new structures. The additively manufactured components are in fact more than 30 % lighter than conventional cast or milled parts. In addition, the CAD data are the direct basis for an additive build job. The omission of tools reduces the costs and shortens the time until the component is available for use by up to 75 %. Since tools are not required in the process, it is now possible at an early stage to produce functional samples of components that are similar to series produced components. This is done without upfront costs for tools. This means that sources of error can be identified in the early stages of the design process in order to optimize the processes within the project. Peter Sander, Head of Emerging Technologies & Concepts, Airbus, Hamburg: "Previously we budgeted around six months to develop a component – now, it's down to one month."

Bionics in the component or product design

Laser melting with metals allows extremely fine, even bone-like, i.e. porous structures to be produced. "Future aircraft components will therefore have a ‘bionic’ look” is what Peter Sander expects. It is not without reason that over millions of year’s nature has produced optimized functional and lightweight construction principles which minimize the amount of resources required in a clever way. Airbus is currently analyzing solutions found in nature in a structured manner with regard to their applicability. By relying on "intelligent exposure strategies" of the laser, it can apply layers to a component in a strategic manner in order to produce custom properties in terms of structure, rigidity and surface quality. Peter Sander: "Initial prototypes indicate great potential of a bionically motivated approach. The process is expected to launch something of a paradigm shift in design and production."

Airbus A350 XWB (Image courtesy of: Airbus)

Airbus A350 XWB (Image courtesy of: Airbus)

Quality as a significant parameter

For aircraft manufacturers, monitoring during the component's build process is one of the most important aspects of the industrial application. Peter Sander: "In practice, "inline process monitoring" with the QMmeltpool QM module from Concept Laser means the system uses a camera and photo diode to monitor the process within a very small area of 1x1 mm². The process is then documented." In 2016 this module will be extended by QMmeltpool 3D. The former, time-related 2D monitoring of the build process becomes a position-related 3D landscape. Instead of exclusively time-related data, the system now additionally delivers position-related signals for definitive allocation, comparable to a computer tomography (CT). These signals make it possible to generate 3D datasets of the part and its structure. A highly accurate 3D landscape of the component is thus created. This allows QMmeltpool 3D to provide local indication of defects in the component. As a result, subsequent inspections and tests can be reduced to a minimum. Furthermore, the data are available directly after the build process, which also saves time. Other QM modules for active quality assurance are QMcoating, QMatmosphere, QMpowder and QMlaser. They measure or monitor, for example, the laser output and also the optimum layer structure of the metal powder and document the entire manufacturing process seamlessly. An additional feature in terms of quality assurance is the capability to work in a closed system to ensure the process remains free of dust and contamination. All disruptive influences that could have a negative influence on the process are intended to be eliminated this way. Frank Herzog: "These days it's accurate to call this a regulated manufacturing process that provides repetition accuracy and process reliability." Prof. Dr.-Ing. Emmelmann emphasizes by saying: "The QA software now enables us to monitor and document key data, such as laser parameters, melt pool parameters, as well as the composition of the inert gas atmosphere. Disruptions due to contamination can be eliminated." Concept Laser can call itself a pioneer in this field too, since the company has been working on different quality improvement/monitoring modules since 2004.

"Green technology" conserves resources

Milling of aircraft parts results in up to 95% recyclable waste. With laser melting, the user receives components with "near-final contours," and the process produces only about 5 % waste. "In aircraft manufacturing, we work with the "buy to fly ratio", and 90 % is a fantastic figure. This is, of course, also reflected by the energy balance", according to Prof. Dr.-Ing. Claus Emmelmann. This makes the process especially attractive when using valuable and expensive aircraft materials, such as titanium. A tool-less manufacturing strategy saves time and improves the cost structure. Targeted energy consumption and conservation of resources are features of the laser melting process. Frank Herzog: "LaserCUSING is a green technology and improves the often discussed environmental footprint of production."

LaserCUSING process in use (Image courtesy of: Concept Laser)

LaserCUSING process in use (Image courtesy of: Concept Laser)

Spare parts supply 2.0: Timely, decentralized and "on demand"

Spare parts constitute a new playing field for "additive aeronauts". In future it will be possible to manufacture them "on demand" at decentralized locations without the need for tools. In the event of a component failure, the spare part can be produced directly on site. Decentralized production networks can be created and global and regional strategies are possible. This minimizes transport distances and, above all, delivery times. As a consequence, maintenance-related downtimes and inspection times for aircraft are reduced. In future it will be possible to significantly reduce the large spare parts depots with parts rarely used that are currently essential given the long life cycles of today's aircraft. A reduced capital commitment increases flexibility and especially the time needed to obtain safety-related components. This is especially attractive given the cost pressure in the aviation industry.

Outlook

Laser melting as a 3D printing technology results in "more intelligent components" which exceed the performance characteristics of conventionally manufactured components in almost every dimension. In particular, in the aerospace industry, manufacturing experts are already speaking of a change in paradigms. Although, due to the batch size structures, the aerospace industry is currently pioneering additive manufacturing, an initial effect on almost all industrial sectors is expected, due to the increase in build rates and build envelope sizes. The key areas in this respect are the automotive industry, dental and medical technology and the tool and machine tool industry. Not least, new business models are created by decentralized production networks as represented, for example, by the Laser Zentrum Nord GmbH. This will also make it possible to return the value created by production from low-wage countries to traditional development and industrial locations in Europe or the USA in order to increase the innovative power and speed there.

Heel Shoes Boat Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login