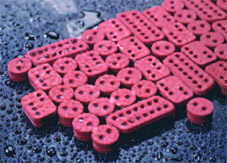

Mass dampers are metal/silicone elastomer composites (Fig. 1). A mass damper can be thought of as a spring/mass system that is tuned to resonate with the vibration that is to be cancelled out. The silicone elastomer acts as the spring and the metal core as the oscillating mass. The factors speaking in favor of silicone for this application are resistance to temperature extremes and long-term mechanical durability. Mass dampers can be made by injection molding. Charging air hoses (Fig. 2) are laminated from different materials (e.g. a fluorinated polymer liner, a silicone intermediate layer, textile reinforcement and a silicone outer sheathing). Silicones' big advantage here is their excellent high-temperature stability. Charging air hoses are produced discontinuously in a multi-stage process, with the hose blank being extruded. After cutting to size, the hose blanks are shaped on metal mandrels and then vulcanised in autoclaves. Liquid silicone rubbers Liquid silicone rubbers (LSR) can be injection molded. They are preferred for producing silicone elastomer moldings in large quantities and/or for very delicate articles. Examples include sealants for cable connectors (weatherpacks, see Fig. 3). Fluid-exuding grades are outstanding here. The exuded silicone fluid improves the seal quality and, by reducing friction, facilitates insertion of cables.

Mass dampers are metal/silicone elastomer composites (Fig. 1). A mass damper can be thought of as a spring/mass system that is tuned to resonate with the vibration that is to be cancelled out. The silicone elastomer acts as the spring and the metal core as the oscillating mass. The factors speaking in favor of silicone for this application are resistance to temperature extremes and long-term mechanical durability. Mass dampers can be made by injection molding. Charging air hoses (Fig. 2) are laminated from different materials (e.g. a fluorinated polymer liner, a silicone intermediate layer, textile reinforcement and a silicone outer sheathing). Silicones' big advantage here is their excellent high-temperature stability. Charging air hoses are produced discontinuously in a multi-stage process, with the hose blank being extruded. After cutting to size, the hose blanks are shaped on metal mandrels and then vulcanised in autoclaves. Liquid silicone rubbers Liquid silicone rubbers (LSR) can be injection molded. They are preferred for producing silicone elastomer moldings in large quantities and/or for very delicate articles. Examples include sealants for cable connectors (weatherpacks, see Fig. 3). Fluid-exuding grades are outstanding here. The exuded silicone fluid improves the seal quality and, by reducing friction, facilitates insertion of cables.

An important field of application for liquid silicone rubber grades are as the soft component in hard/soft composite moldings. Fig. 4 represents a plug housing. The hard component may be of metal, glass, ceramic or various plastics (e. g. PA,PBT,PET or PEEK).There are big advantages to producing hard/soft composite parts using a self-adhesive, fast curing liquid silicone rubber grade. A self-adhesive LSR requires neither an undercut nor a primer for anchoring the two components. Because liquid silicone rubber (such as Elastosil LR 3070) bonds very rapidly to the thermoplastic substrate, thermoplastic/ silicone elastomer composites can be produced in a single operation by a fully automated two-component injection molding process. Such a process can produce, for example, multifunctional steering-wheel switches or membranes for electropneumatic transducers (Fig. 5). Fluorinated silicone rubber grades The outstandiNike Air Max 90

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login