AUTOMATED packaging is driving technology and product trends at the 22nd China International Exhibition on Packaging Machinery & Materials to be held from March 9 to 11, 2015 at Area A, China Import and Export Fair Complex in Guangzhou, Guangdong in China.

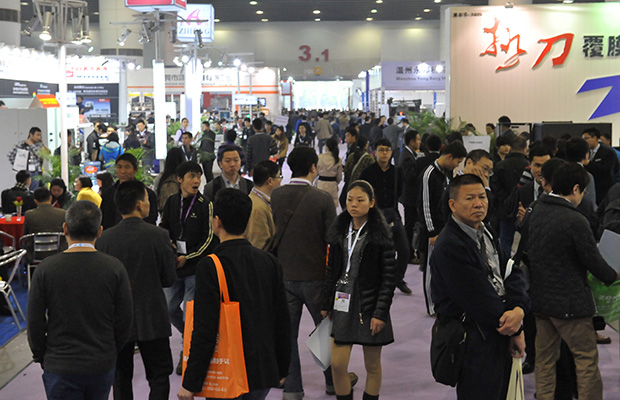

Sino-Pack 2015 will gather together more than 600 exhibitors from over 20 countries and 35,000 trade visitors in its 40,000 sqm exhibition space.

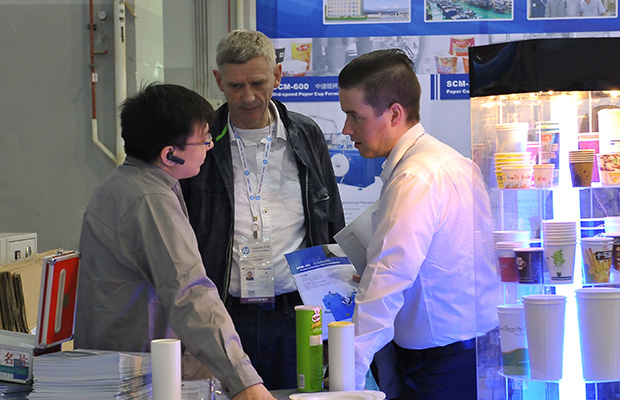

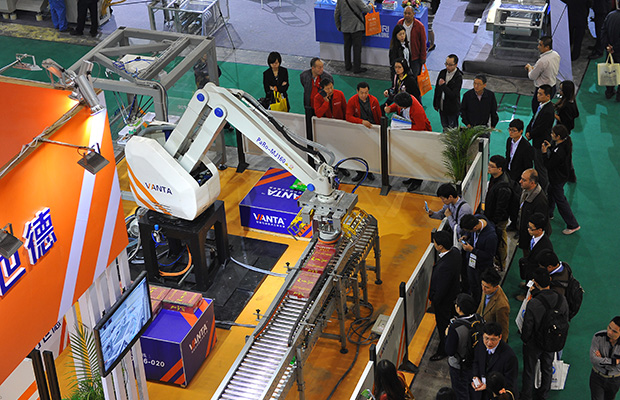

Local manufacturers will showcase recent innovations and breakthroughs in efforts to keep pace with technological developments in the global packaging industry. To heighten visitors’ trade show experience, there will be live demonstrations of the latest packaging machineries such as intelligent packaging equipment and packaging robots. Companies will also be able to get personalised solutions to increase their competitiveness.

Leading companies will fill more than 80% of exhibition space. These include FANUC, ABB, KUKA, Staubli, Triowin, GSK, SIASUN, Go-Well, Enmair, Tech-Long, Gurki, Omori Changkong, Yinhui, Metler-toledo, Ishida, Schmalz, Softlink, Best Crown, Nordson, Youngsun, Hualian, E-shrink, Zhongcheng, Songben, Xutian, Dachuan, Bohui, Fullmore, To-U, SITI, Multiwigh, Excellair, Packmate, Alphpack, Yuanxu, V-Pack, WINSTAR, Chyan, Hitachi, Viedojet, Mingyu, Makrotek, Sunine, KGK, and Mingjia.

Global demand for packaging machinery posts an annual growth of 5.3%, according to a report from the National Bureau of Statistics of China, General Administration of Customs, and Department of Commerce of PR China. This represents a huge market for China, whose packaging machinery industry records an annual growth of 16%.

China is currently the world’s number one manufacturer and exporter of packaging machineries. Manufacturers agree trends point to increased automation and intelligent packaging.

Over 35,000 trade visitors are expected to attend Sino-Pack 2015 in Guangzhou

Exhibitor highlights

Shanghai FANUC (booth 1220) has been specialising in robotic technology since 1974. It is currently the only company in the world to use robots in manufacturing robots. It became the first company worldwide to sell more than 200,000 robots in June 2008. In 2011, it ranked number one by selling over 250,000 units.

Fanuc produces robots and intelligent equipment, and provides vision–guided integrated robotic systems. Its over 20 series of robotic products can withstand loads of 0.5 kg to 1.35 tons and can be used in various phases of the construction process, including assembly line, material handling, welding, casting, painting, and palletising.

Automation comes alive at Sino-Pack 2015

ABB Engineering (Shanghai) Ltd at booth 1120 serves as ABB Group’s global robotics headquarters and its robotics research, development, and production base. The company uses advanced robot production lines to deliver complete, safe, and sustainable solutions for the automotive, foundry, metal fabrication, plastics, packaging and palletising, and electrical and electronic equipment industries.

ABB Group achieved $42 billion in sales revenue in 2013. It has more than 100 production bases worldwide and over 150,000 employees. The company’s new ABB IRB 1200 robot boasts material handling capability, a flexible OS, and compact mechanic rhythm.

Shenyang SIASUN Robot & Automation Co. Ltd (booth 1806) has the largest robot production base in China and five holding subsidiaries in Beijing, Shanghai, Hangzhou, Shenzhen, and Shenyang. It is constructing two automation industrial bases in Hangzhou and Shenyang, which it plans to turn into the world’s most elite technology centre for automation and intelligent equipment using robots to manufacture robots.

The company’s SRB360/500A robot series features maximum flexibility for heavy-lifting. It packs 500 kg maximum capacity for level handling, and 2,525 mm maximum radius reach.

Southern China’s main industrial base for computer numerical control (CNC) systems, GSK CNC Equipment (booth 1515) is a leading supplier of machine-controlled CNC solutions in China. GSK offers CNC systems, servo drives, servomotors, and industrial robots. It handles production and research development on injection molding machines with precise CNC systems, CNC machine tools marketing and engineering, and CNC personnel training program.

The only company in China producing industrial robots at large volumes, Shanghai Triowin Technology Co. Ltd (booth 1212) offers its Triowin robots and equipment. Its new factory can produce 2,000 units of material-handling robots per year. Triowin is the sole China company that can compete with international industry leaders from Japan, Germany, and Sweden. It has obtained CE certification. Exports go to Europe and North America.

Sino-Pack 2015

Venue: Area A, China Import and Export Fair Complex in Guangzhou, Guangdong

Organiser: Adsale Exhibition Service Ltd

T: +86 21 5187 9766 *299

F: +86 21 6469 3665

E: pfp@adsale.com.hk

W: www.ChinaSinoPack.com

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login