THE TRADITIONAL way of formulating, mixing and packing powder is using a ‘mixing tower’ whereby a single recipe is running from top to bottom until such time that enough has been produced and the recipe changes. This methodology is not particularly flexible if several recipes need to be produced per day, but it is easy to keep track of what is being produced. What goes in at the front end eventually moves through to the final pack.

A more flexible and agile method for mixing and packing is to apply ‘parallel processing’ using Intermediate Bulk Containers (IBCs) which allow several different recipes to be processed at any one time. Overall production output can typically be doubled with this approach as well as reducing the necessary inventory. With ‘parallel processing’, whilst the efficiency of the system is dramatically improved, the running of several recipes all at one time in closed vessels (IBCs) comes with the challenge of keeping track of which recipe is processed where and what action to perform next.

How can you keep track?

Paper-based systems for keeping track of the IBCs are generally fit for purpose. They are widely used and perfectly acceptable in the majority of cases. However, if the system expands beyond the sensible application of a paper-based system it becomes necessary to apply an automated, secure system instead.

In addition, many customers require the manufacturer to adopt such rigorous tracking that only an automatic system can provide this adequately.

MES is the answer, right?

This issue opened up the opportunity over 10 years ago for software developers to extend the capabilities of MES (Manufacturing Execution Systems). They started to promote bespoke software tracking systems to fit the specific needs of the manufacturer. This approach appears very attractive, the system will communicate with any ERP business management system and, as the jewel in the crown, it’s totally flexible, anything and everything can be included!

However, each MES system has to start from scratch. Often, once the system is installed and any bespoke issues ironed out, it has typically taken 3-4 times longer than anticipated with final costs at least doubling. In some cases, the end solution has become so complex and fragile that the users have had to revert back to their old paper based system!

A simpler solution to operate

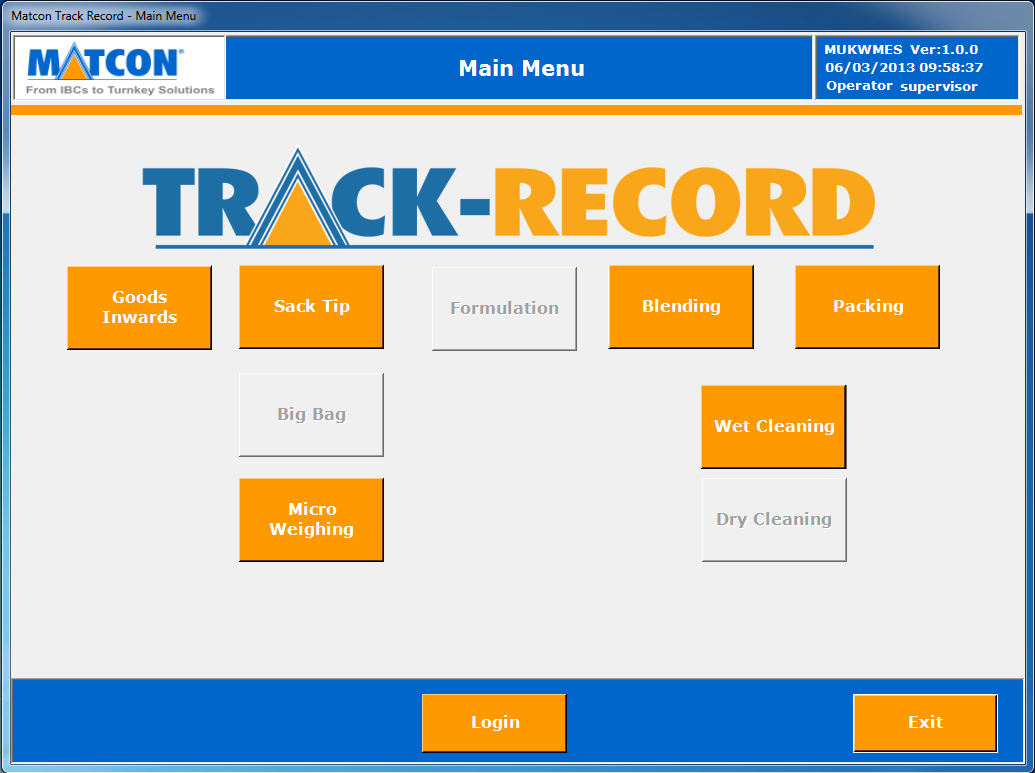

In response to this, Matcon launched a simple yet effective answer called Track-Record for use with their IBC System. It captures data from Goods Inwards through all the processing stages to Packing.

Each individual IBC is identified by RFID tags, which are ‘read’ at each process station. The system will guide operators as to the next step to be taken or will alert them if they are in danger of performing the wrong task.

A simpler solution to implement

Track Record can be installed quickly and reliably. It undergoes continuous development so you are not stuck with the version at the time of installation, all future versions and features are available as upgrades.

It can be retro-fitted to an existing Matcon IBC installation. So if your IBC system has expanded to meet demand, and you now need something more comprehensive, this can be added with minimum disruption.

It is flexible and can also be integrated into existing MES software and used on non-Matcon equipment such as sack tipping, fixed mixers and packing.

More than just tracking

Track Record provides more than just traceability of recipes and ingredients. It gives full stock control, which is up to date based on your latest batch run.

It also assists in identifying and eliminating where losses might be occurring. It will stop incorrect blending or the spoiling of a batch by inaccurate formulation. It helps to ensure that each batch is right first time, every time, for a great ROI & maximum security.

Scope of processes within TRACK-RECORD

Raw material registration

- Verify ingredient quality

- Check Lot number & Best Before date

- Generate barcodes for process safety

Manual weighing

- Reduce operator error

- Campaign by ingredients

- Graphical display of target & tolerance

- Generate barcodes for process safety

IBC filling

- Verify IBC is empty & clean

- Verify each ingredient addition

- Operator prompts remove error

- RFID coding ensure correct sequence

Blending

- Verify IBC correctly formulated

- Autodownload of recipe parameters

- Capture real-time blend data

Packing

- Interface with third party equipment

- SKU verification

- Check IBC status

- Record number of bags/sacks filled

Cleaning

- Check suitability of wash requirements whether wet or dry

- Check IBC empty

- Capture real-time wash data

Supervisory control

- Ingredient, batch & operator traceability

- Real-time & historical traceability

- Recipe creation/import

- Works Order generation

- Raw material availability control

- Removes waiting & improves OEE rates for high throughput

KEY BENEFITS

- Real-time traceability of all ingredients

- Step-by-step validation throughout the process

- Reduced human error - unique Operator identification

- Stock Control

- Right first time – every time

- Can be retro-fitted onto existing Matcon system

- Customer satisfaction through brand security

Contact Matcon for more information or if you would like to discuss how Matcon systems could improve the capability and profitability of your manufacturing processes.

Nike Magista Obra Low

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login