Waterborne UV curable coatings – Eco-Friendly coatings – have been developed to replace conventional UV curable coatings with VOC emissions. The challenges of waterborne UV curable coatings have two aspects. One is that discoloration may occur when resins are exposed to Ultra Violet (UV) light radiation from natural sunlight. Waterborne UV-curable light stabilizers are applied to the surface for protection. The other is yellowing during curing process. This problem will affect customer’s product quality and therefore increase product costs.

The novel light stabilizer (NLS) is developed specifically for waterborne UV curable coats to reduce yellowing during curing process. Design of Experiment (DOE) was used in this study. Test data showed that the NLS in a waterborne clear UV curable coating would not have negative impact to cure speed. The results confirmed that increasing the concentration of NLS in the top coat can effectively reduce yellowing during curing process. Furthermore, data also showed that by increasing the coating thickness, the yellowing during curing process can not be improved to some degrees.

UV curing processes have been used extensively in many different industries such as packaging, printing inks and protective coatings for wood, plastics and metal etc. However, UV curable coating has odor, emits monomers and does not guarantee zero VOC emission. On the other hand, UV curable waterborne coating has both the advantages of waterborne coating and UV curable coating such as non-toxic, pollution-free, and safety in use. In recent years, research and development in this area has grown faster.

In the dry fast system, UV curable coatings play an important role. Light stabilizers package can include UV absorbers (UVA) and hinder amine light stabilizers (HALS) which are known to prevent coating damages caused by UV irradiation. On the other hand, photo initiator absorbs UV energy to initiate curing processes. UV absorber absorbs UV energy to prevent coatings damages. As a result, UV absorber and photo initiator are competing against each other for UV energy and create a negative impact to the cure speed.

This article demonstrates Everlight's recent development on liquid NLS for waterborne UV-curable coating. Our objectives are effectively reduce yellowing during curing process and eliminate negative impacts to the curing speed.

Experiment results

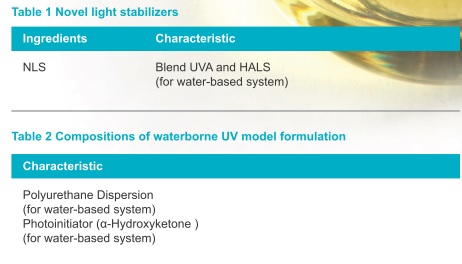

The model formulation used in this study was Novel Light Stabilizers (NLS) and compositions of waterborne UV curable coating. Their detail compositions are shown in Table 1 and Table 2. Design of Experiment (DOE) was used to design test runs as well as to analyze test data. DOE technique allows the team to validate the data.

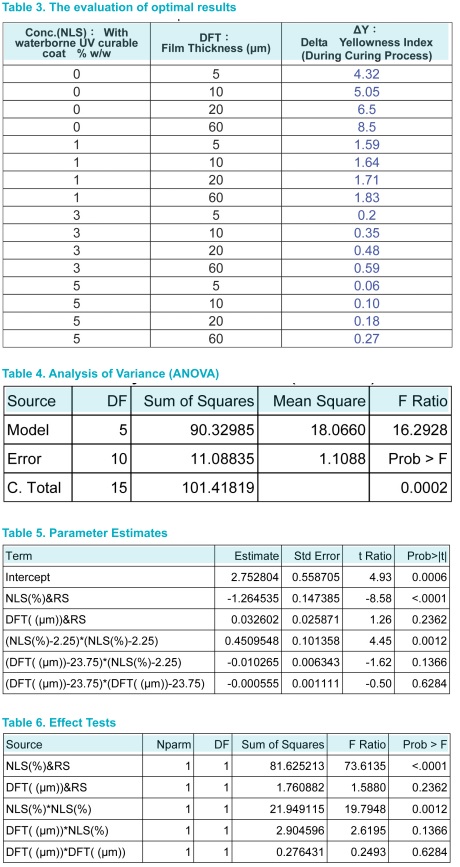

Optimal results (as shown in table 3) were used to identify factors that reduce yellowing. –Concentration of NLS (novel light stabilizer) and DFT (dry film thickness). Analysis of variance (as shown in table 4), Parameter estimates (as shown in table 5) and effect tests (as shown in table 6) are analyzed from table 3. Mathematical model derived from data indicates two factors NLS and DFT exhibit some degrees of influence to reduce yellowing.

The

ΔY = 2.75 - 1.26*(NLS%) + 0.032*DFT + 0.451*((NLS% - 2.25))2 ± 2*1.05 -----------equation(1)

NLS is developed specifically for water borne UV curable coats. Test data showed its negative coefficient that NLS in a waterborne clear UV curable coating can get good performance. For NLS, the effect of reducing yellowing during curing process was about 79%(see Table 7).

Film thickness is the less significant factor in this study (see eq. 1). Test data is showed Its positive coefficient that DFT of waterborne clear UV curable coating can’t get good performance. For DFT, the effect of reducing yellowing during curing process was only about 0.6%(see Table 7).

The prediction profiler (as shown in Figure 8) show that effect of reducing yellowing of NLS and DFT after curing process test. The data also suggested that by increasing 3.44% NLS in waterborne UV curable coat and 5μm coating thickness can get the best performance (Delta Yellowness Index ΔY=-0.76) ( as shown in Figure 8).

Response surface methodology (RSM) is a collection of mathematical and statistical techniques for empirical model building. By careful design of experiments, the objective is to optimize a response (output variable is ΔY) which is influenced by several independent variables [input variables are NLS (%) and DFT]. The highlighted area from this model which is the optimal result in reducing yellowing during curing process.

Waterborne based UV curable coatings were made with wire-wound rod on coated Leneta charts. The dry film thickness (DFT) was 60 μm and heated in an oven at 50℃ for 10 min. The next were cured under a 1 x 150w/cm high-pressure Hg lamp. Cure speed was recorded when coating left no visible marks after a finger nail scratched across the coating surface a few times.

The final results confirmed the team"s objectives which NLS package is effectively reducing yellowing during curing process and not having impacts to cure speed. Furthermore, data also suggesting by increasing thickness is not improved yellowing problem.

Setting the future trend

Eco-friendly coatings are the future trend in the coating development. In this article which highlighted the benefits of using NLS in waterborne UV-curable coating system and make it possible to the formulator to choose from.

Coating manufactures may still need to run the experiments to confirm its coating systems compatibility. Also, a tailor made UV absorber and light stabilizer package can be offered for special needs.

- By Yung-Chi Yang, Ming-hua Lai, Yu-Shu Sung , Yin-Ting Lai, Chung-Han Lu, Hsiao-Fang Chiu, Chih-Hsien Chein, Steven Lee and Dr. Yao-Hsing Huang

Everlight Chemical Industrial Corporation

6th Fl, 77 Tun-Hua S. Rd. Taipei, Taiwan R.O.C

Tel: +886-3-4837682; Fax: +886-3-4837683; gigi@ecic.com.tw; www.everlight-uva.com

Air Force 1 Foamposite

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login