Blow moulding or blow forming remains a popular technique in manufacturing plastic products and plastic parts. In the upcoming K 2010, new range of blow moulding machines are expected to draw interests and create demand for their flexibility, lower energy consumption, speed and high production capacity. Krones AG will be surprising visitors to this sectoral meet-up with an oven concept called FlexWave for the Contiform stretch blow-moulding machine - a new and innovative heating technology. FlexWave scores primarily with its significantly lower energy consumption compared to the infra-red technologies currently available on the market. It also achieves an unprecedented degree of process flexibility, independently of preform colour, PET material or proportion of recyclate.

The stretch blow-moulding machines from the Contiform series synergise technical sophistication and long years of experience in mechanical engineering. To clients' specific requirements, the machines are available in a choice of different sizes and model variants. This enables Krones to cover the entire spectrum of bottles involved, from 0.1 all the way up to 5.0 litres. Depending on the container size concerned, the Contiform can reach a maximum output of 72,000 containers an hour. Wilmington Machinery, a manufacturer of high speed rotary coextrusion blow moulding systems and structural foam injection moulding machinery, is showcasing its new and very popular small bottle (SB) high speed rotary blowmoulding systems for producing bottles size from 80 to 1000ml. The technology has been expanded to accommodate dual parison capability allowing production rates up to 500-1000 bottles per minutes. The SB technology is ideally suited to monolayer or multilayer containers for food, dairy, juice and liquid yogurts applications. The success of this technology is due to the simplicity of handling the bottles at very high speeds and the bottle weight reductions because of the very tight weight variation and material distribution capabilities of the blow moulder. Wilmington Machinery also produces a line of larger rotary blow moulders for 1litre to 5 litre containers for liquid detergents, cooking oil, motor oil and food applications. These system are available with up to 30 cavities and can also be adapted to dual parison. US-based Wilmington Machinery is a 40 year old company specialising in the design, manufacturing and support of high speed rotary blow moulding machinery for packaging, high output structural foam moulding machinery and proprietary plastic processing machinery for numerous companies.

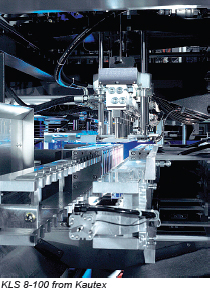

Long-stroke machine with high capacity Kautex Maschinenbau is introducing its new model KLS 8-100 high performance blow moulding machine at K 2010. This new long-stroke extrusion blow moulding machine with new machine guarantees high production capacity. With its integrated leak detection, automatic article weight checking and visual article inspection system, the machine is capable of identifying off-spec production materials, which are automatically placed in the reject bin. The KLS 8-100 can also continuously measure and display energy usage and efficiency. Coupled with the company's inbuilt preventive maintenance system, the new machine allows for complete monitoring of the manufacturing process. Jomar Corporation is also exhibiting two new Injection Blow Moulding (IBM series) machines, the Model 85S HYBRID and the Model 20. The new 85S HYBRID features an electric screw drive rather than a hydraulic drive unit. The electric screw drive, incorporated with Jomar's accumulator system, enables reduction from the standard 75 HP motor down to a 30 HP motor. Energy consumption is reduced by 36% compared with the standard Jomar machine that has the vertical plastifier and by 50%Nike Zoom Kobe IV

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login