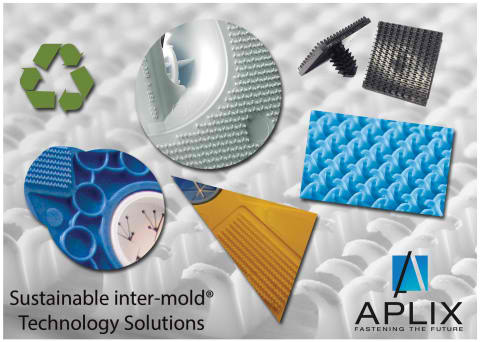

Aplix introduced its latest sustainable capabilities with the use of biodegradable additives during the inter-mold process. The "inter-mold technology" is a breakthrough patented one-step injection molding solution which allows the creation of hooks directly into plastic parts.

Aplix partnered with ENSO Plastics, a global leader of environmental plastic solutions, to utilize a specialized additive for Polypropylene, Polyethylene (including LDPE, HDPE) resins to enhance the biodegradation process of their inter-mold technology.

“As part of Aplix’s commitment to protecting the environment, we now offer a new sustainable dimension to our inter-mold technology,” stated Quresh Sachee, VP of Global Sales & Marketing.

Adding the ENSO RESTORE additive to the resin allows for the natural process of biodegradation within landfill environments of traditionally non-biodegradable plastics, returning the polymer to its natural elements reducing both waste and overall product carbon footprint. The performance is tested under recognized ASTM standards; D5526, Bio-Methane Potential (BMP) as well as D5511.

The inter-mold process is compatible with a wide range of injection-molded thermoplastics. A number of resins have been used for automotive, cleaning and medical applications including polypropylene, polyethylene, nylon, acetyl and thermo-plastic urethanes (TPU).

Aplix’s inter-mold technology is easily implemented into injection-molding machinery and does not require moving parts or add-on equipment.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login