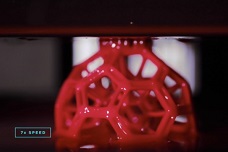

CARBON3D delivers a breakthrough technology for layerless 3D printing with its new Continuous Liquid Interface Production technology (CLIP).

CLIP is designed to grow commercial-quality parts from a pool of resin by harnessing light and oxygen instead of printing them layer by layer. This innovative approach to polymer-based 3D printing ups the ante in state-of-the-art 3D printing in three ways: It boasts a game-changing speed that is 25 to 100 times faster than conventional 3D printing. It produces objects of commercial quality with consistent mechanical properties. It works with a wide range of polymeric materials.

The technology, which was introduced at the TED conference this month, and as the cover story in the journal Science, features a special window transparent to light and permeable to oxygen like a contact lens. This window controls the oxygen flux and enables CLIP to create a “dead zone” in the resin pool just tens of microns thick or about 2 to 3 diameters of a red blood cell to prevent photopolymerization. From just above this dead zone emerges the physical object continuously while a series of cross-sectional images of a 3D model plays into the resin pool from underneath.

The technology, which was introduced at the TED conference this month, and as the cover story in the journal Science, features a special window transparent to light and permeable to oxygen like a contact lens. This window controls the oxygen flux and enables CLIP to create a “dead zone” in the resin pool just tens of microns thick or about 2 to 3 diameters of a red blood cell to prevent photopolymerization. From just above this dead zone emerges the physical object continuously while a series of cross-sectional images of a 3D model plays into the resin pool from underneath.

Unlike the traditional mechanical approach, CLIP uses a tunable photochemical process to rapidly transform 3D models into physical objects. It carefully balances the interaction of UV light—which triggers photo polymerization—and oxygen—which inhibits the reaction—to grow objects continuously faster than traditional 3D printing.

Watch Carbon 3D Demo

In addition, CLIP produces consistent and predictable mechanical properties that are smooth on the outside and solid on the inside as opposed to conventionally made 3D printed parts whose mechanical properties vary depending on the direction the parts were printed.

According to Carbon3D CEO and co-founder Dr. Joseph DeSimone, “Current 3D printing technology has failed to deliver on its promise to revolutionize manufacturing. Our CLIP technology offers the game-changing speed, consistent mechanical properties and choice of materials required for complex commercial quality parts.”

In another development, the company has announced a partnership with Sequoia Capital to lead its Series A round of financing in 2013 along with Northgate Partners, Piedmont Capital Partners, and Wakefield Group.

Silver Lake Kraftwerk led the Series B round of financing in 2014 with Northgate Capital and Sequoia Capital, for a total of $41 million to commercialize the technology.

Carbon3D board member and Sequoia Capital partner Jim Goetz said: “If 3D printing hopes to break out of the prototyping niche it has been trapped in for decades, we need to find a disruptive technology that attacks the problem from a fresh perspective and addresses 3D printing’s fundamental weaknesses. When we met Joe and saw what his team had invented, it was immediately clear to us that 3D printing would never be the same.”

According to Adam Grosser, Carbon3D board member and managing director at Silver Lake Kraftwerk, “We had studied the additive manufacturing ecosystem comprehensively and had concluded that the promise far exceeded the current reality in the marketplace. When we witnessed the CLIP process, we believed we had found a company that had invented a solution to speed, quality, and material selection. We are proud to work alongside Carbon3D to create a new category of 3D manufacturing.”

Girls Air Jordan 1

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login