THURNE High Speed Slicing Systems introduces a dedicated slicer for cheese applications.

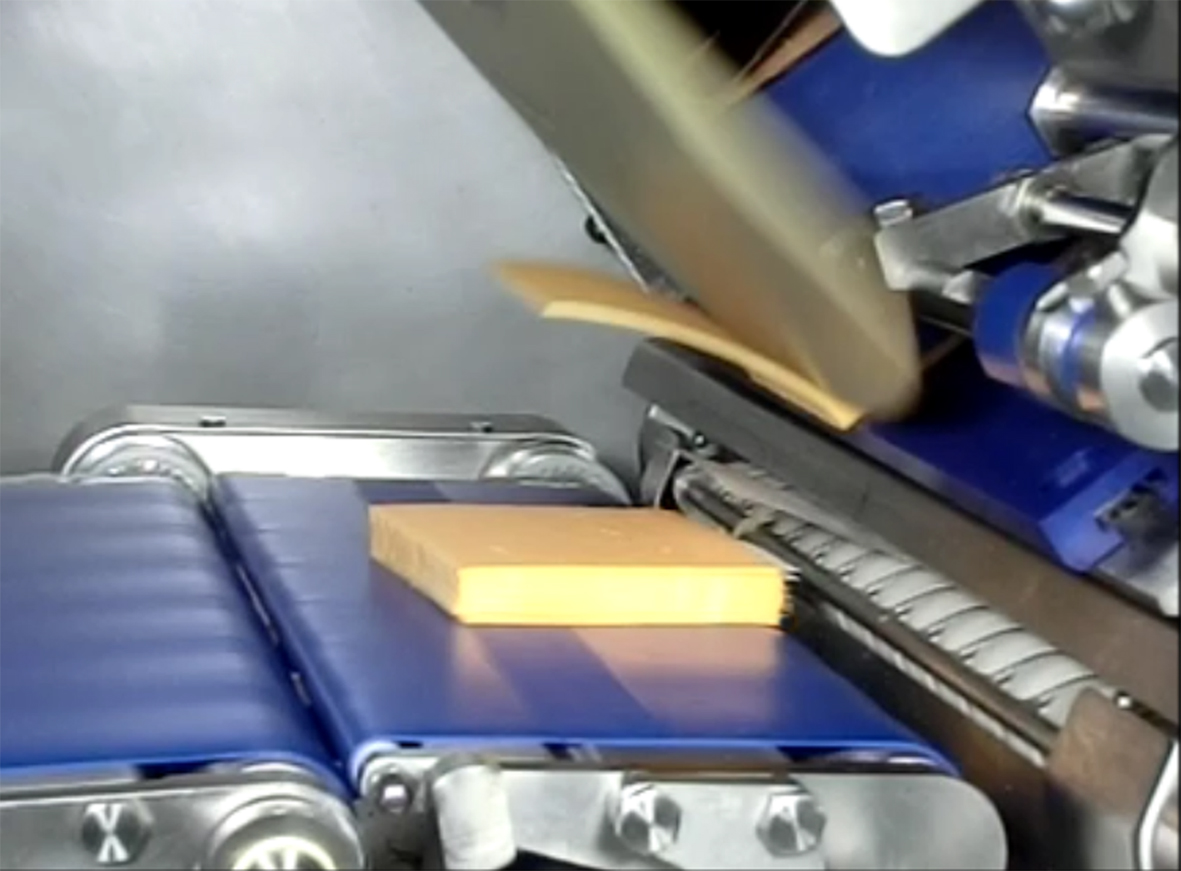

Based on the proven compact Polyslicer 1000 platform, the new CS 1000 features a range of cheese specific components and blades that reduce friction, providing better slice thickness control and ensuring high quality product presentation.

The machine is available with both orbital and involute head for slicing of stacked (<100mm) and shingled retail and food service packs at high speeds up to 1500 rpm. An optional Interleaver, which can be added as a retrofit if required, supports multi-lane interleaving of shingles and stacks up to 80mm at speeds up to 700 slices per minute.

“Our Interleaver works differently from other systems in the market”, explains Chris Howard, VP Sales, “the product and the interleaving material are cut by two separate cutting mechanisms, enabling us to choose the product blade best suited to the hardness and texture of the cheese to be sliced. This circular or involute blade will deliver consistent product placement and pack presentation and – without reducing its edge by also cutting paper or film – stay sharp and perform well for longer.”

Having a separate cutting mechanism for the interleaving material also has the added benefit of enhanced control over the positioning of the paper or film, as well as providing easy access for fast reel changes, maintenance and cleaning.

The slicer will be on show at the International Cheese Technology Expo in Milwaukee, WI, USA, 12–14 April 2016, where Thurne based in Norwich, UK, will join Middleby sister brand RapidPak on booth 1103.

Air Max 90 Classic

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login